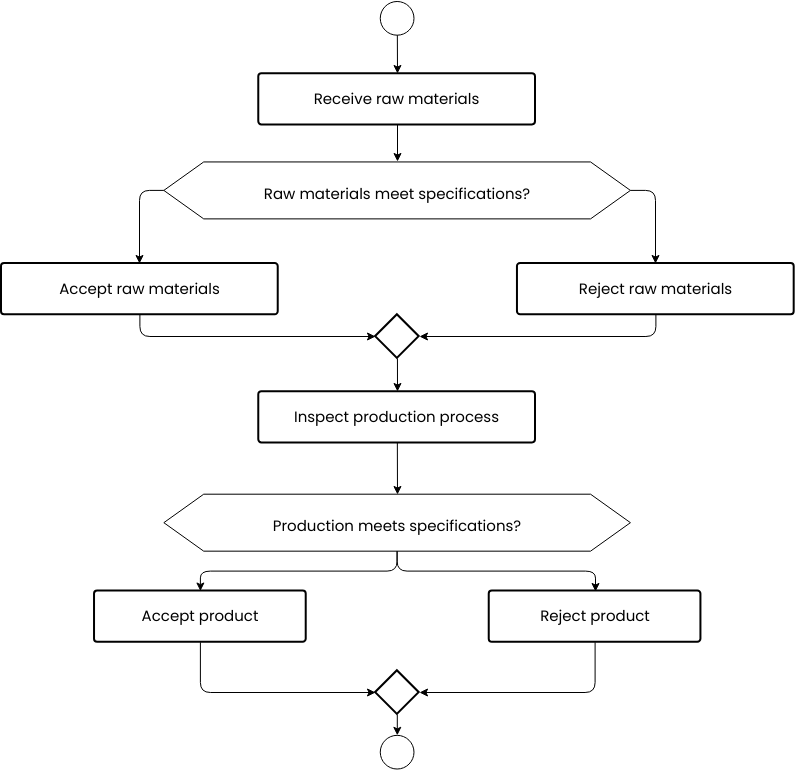

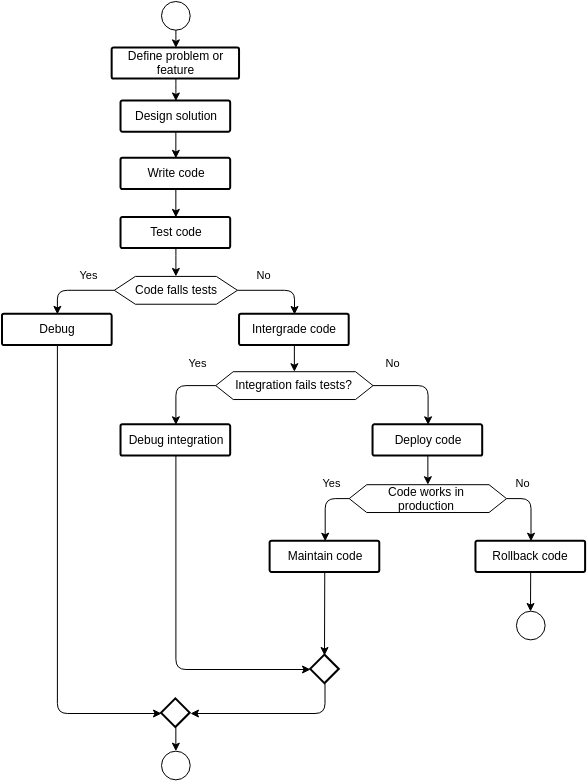

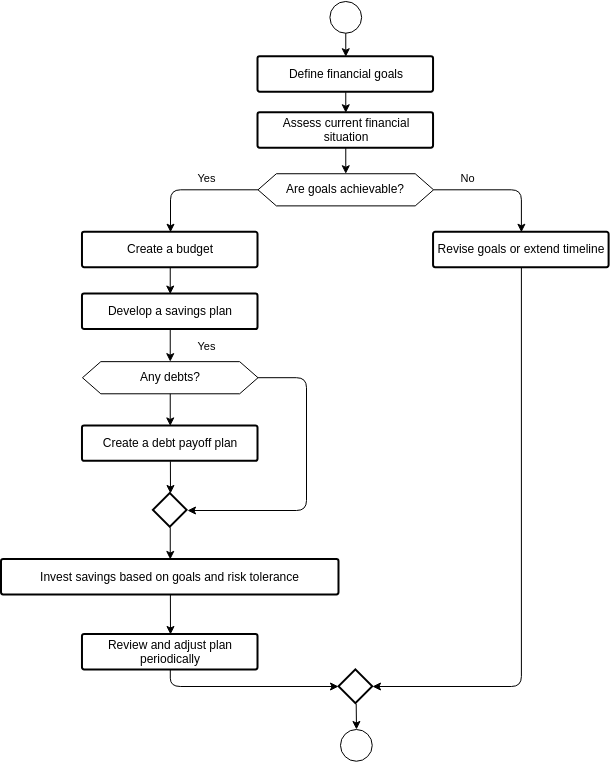

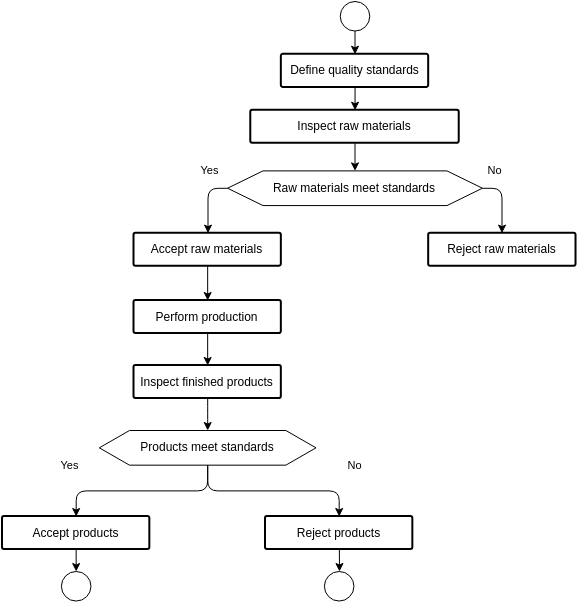

Quality control is an essential aspect of any manufacturing process. To ensure that the final product meets the required quality standards, a quality control flowchart is often used. The flowchart outlines the various steps involved in the manufacturing process and the quality control measures that need to be taken at each step.

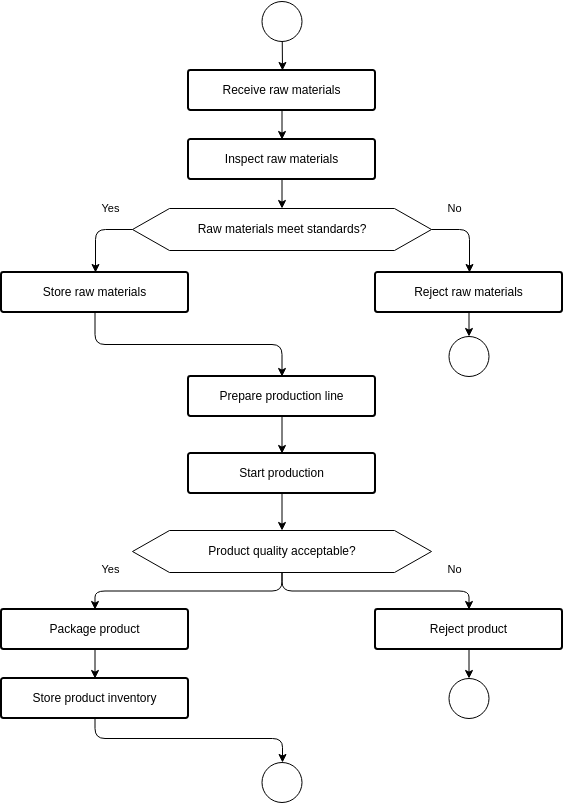

The first step in the quality control flowchart is to receive the raw materials. This involves checking the quality and quantity of the raw materials that are delivered to the manufacturing facility. Any discrepancies or defects must be reported and resolved before the raw materials are accepted for use in the production process.

The next step is to accept the raw materials. This involves verifying that the raw materials meet the required quality standards and are suitable for use in the production process. This step is critical, as it ensures that the final product will meet the required quality standards and that any issues with the raw materials are identified and resolved before production begins.

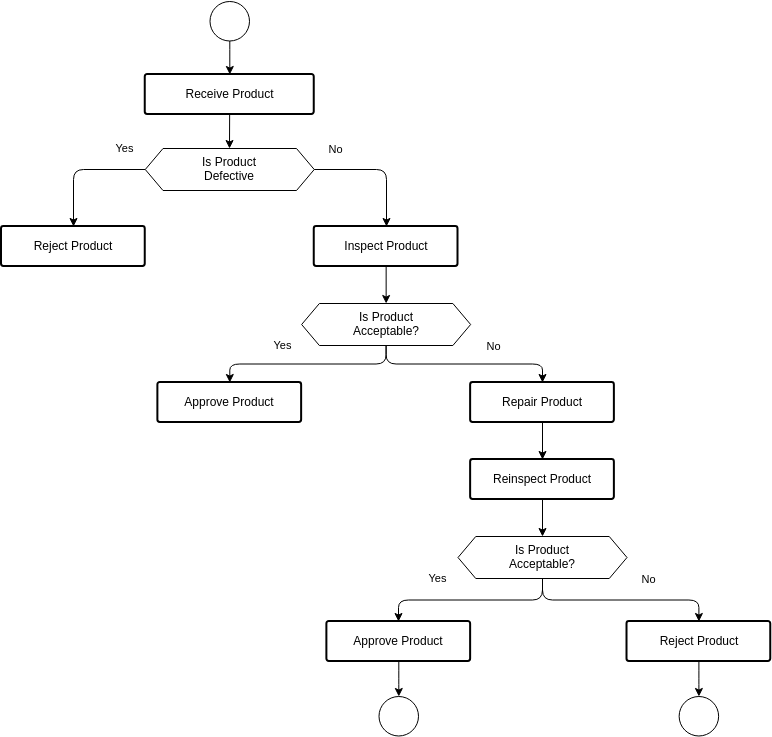

The third step in the quality control flowchart is to inspect the production process. This involves monitoring the production process to ensure that it is being carried out according to the required standards and specifications. Any deviations or issues must be identified and resolved as soon as possible to prevent any impact on the final product's quality.

The fourth step is to accept the product. This involves checking the final product to ensure that it meets the required quality standards and specifications. This is the final step in the quality control process, and it is critical to ensure that the product is of the required quality and that any issues are identified and resolved before the product is shipped to customers.

Benefits of creating this flowchart

Creating a quality control flowchart can provide numerous benefits for manufacturing processes. By outlining the steps involved in the manufacturing process and the quality control measures to be taken at each step, manufacturers can improve product quality, increase efficiency, and ensure consistency. This helps to build trust with customers and improve the company's reputation. Additionally, following a standardized quality control flowchart can help manufacturers to comply with regulations and industry standards, demonstrate their commitment to producing high-quality products, and identify areas for continuous improvement.

Overall, a quality control flowchart is an essential tool for ensuring the manufacturing process is carried out consistently, efficiently, and to the required quality standards. By regularly reviewing and updating the flowchart, manufacturers can identify inefficiencies, make changes to improve efficiency, and ensure ongoing success and growth for the company.

earching for some flowchart templates? Go to Visual Paradigm Online and select some designs for customization now!