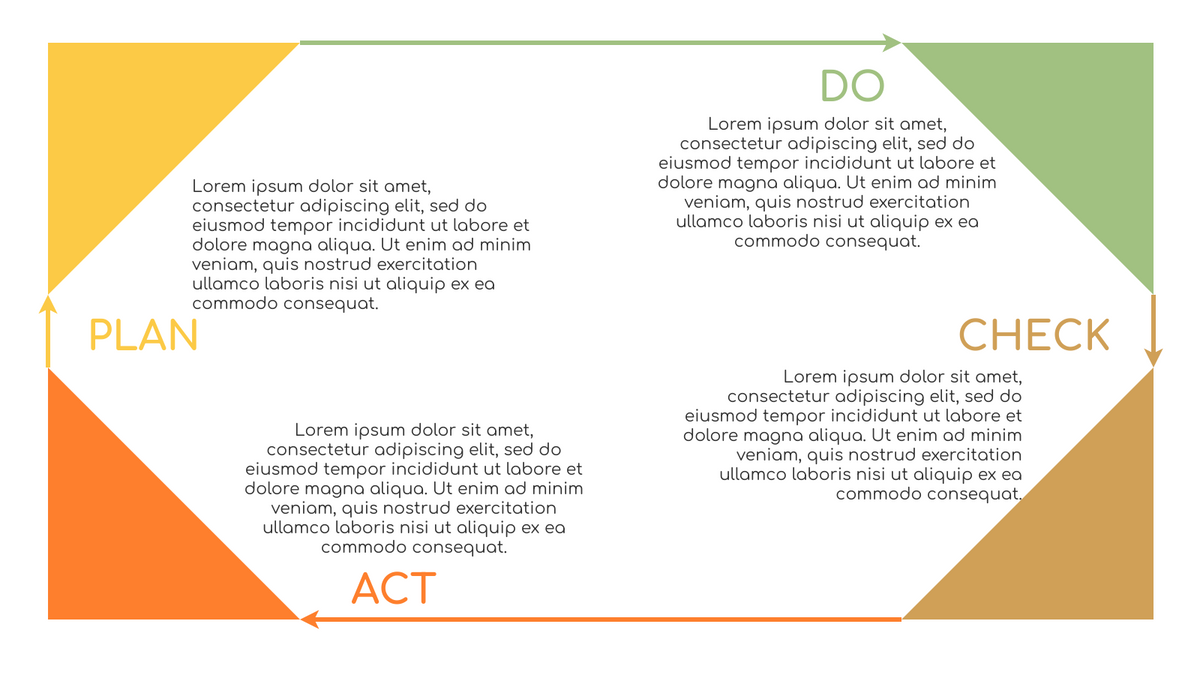

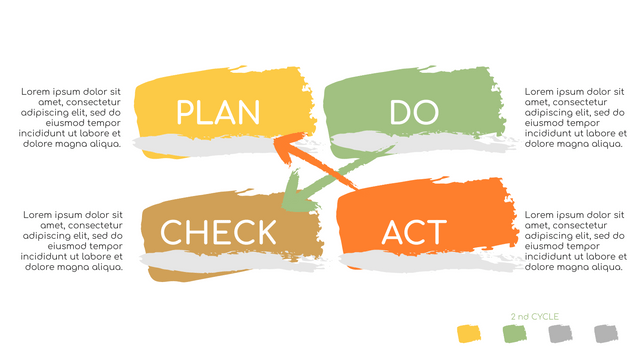

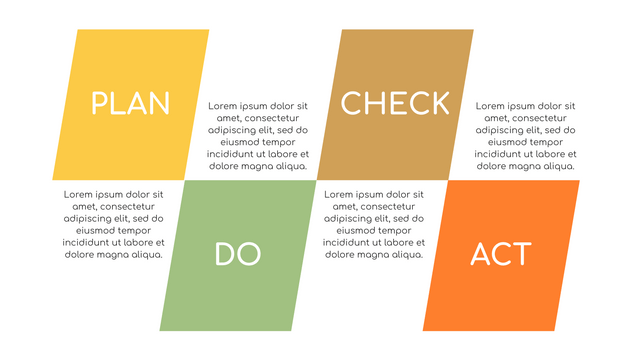

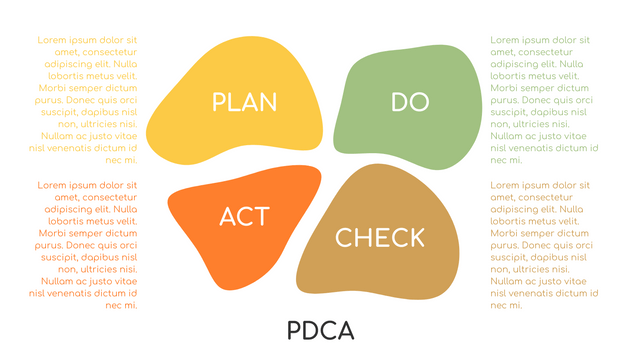

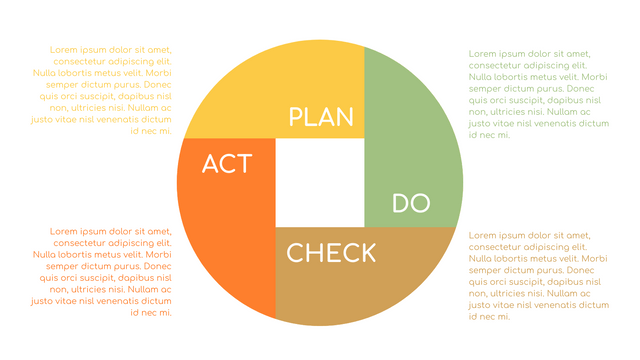

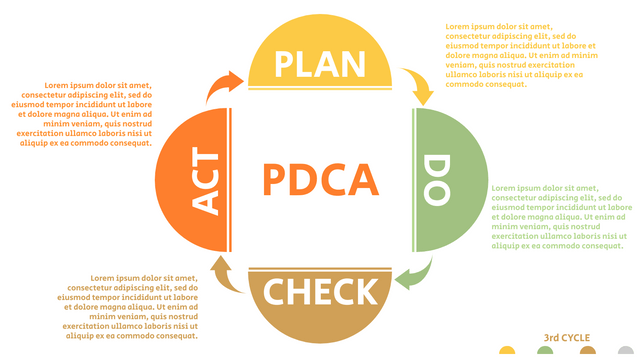

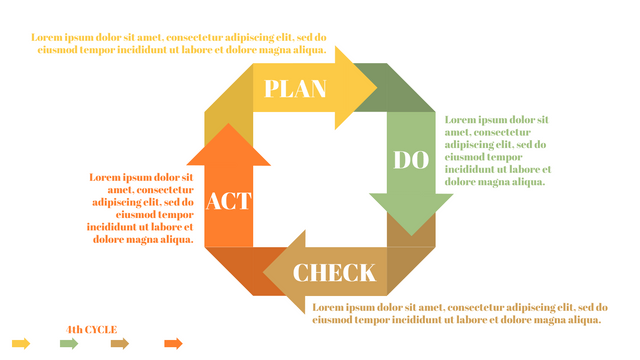

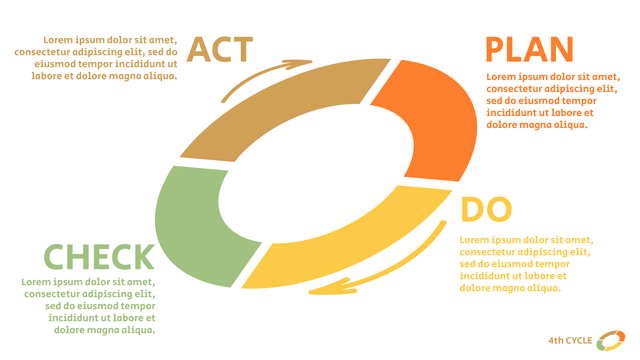

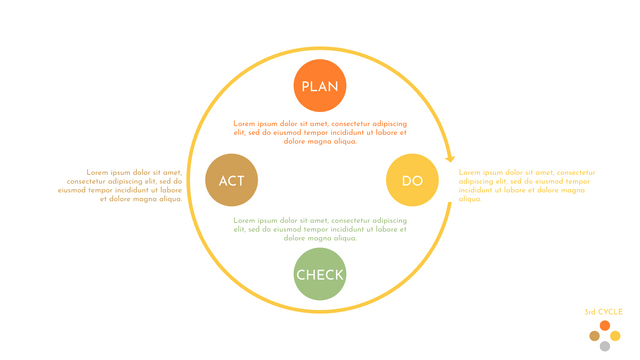

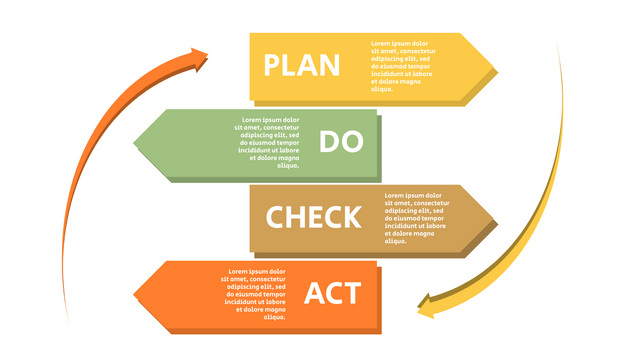

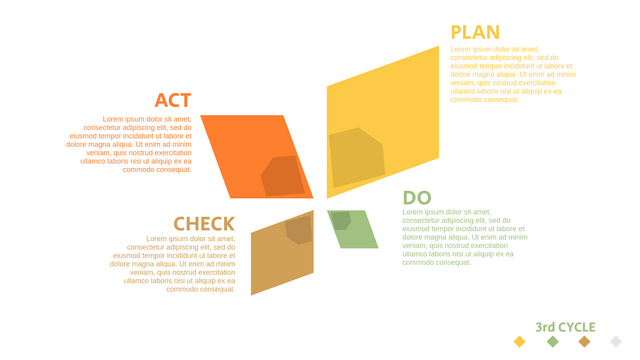

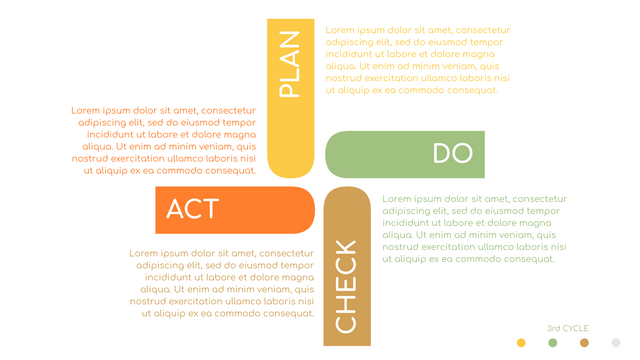

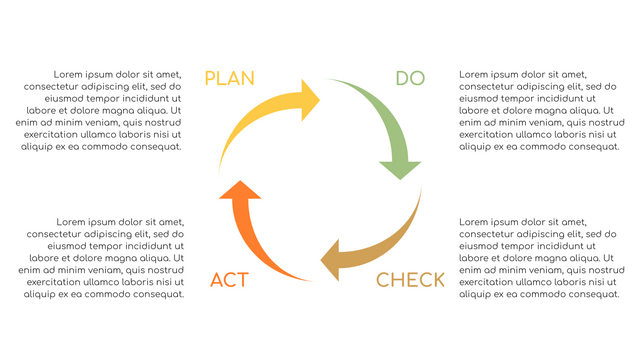

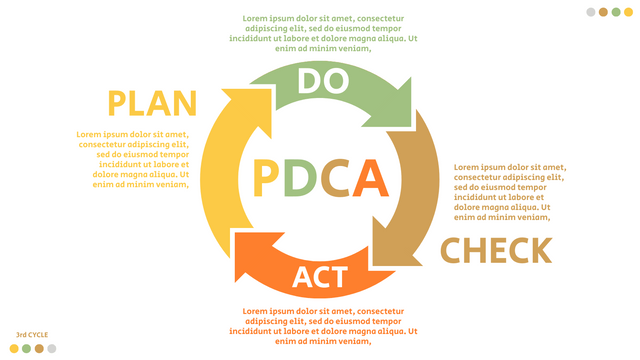

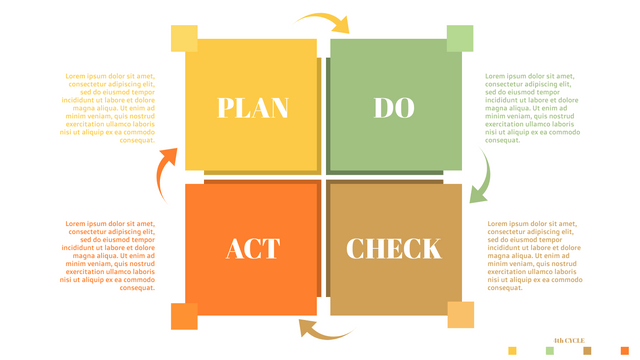

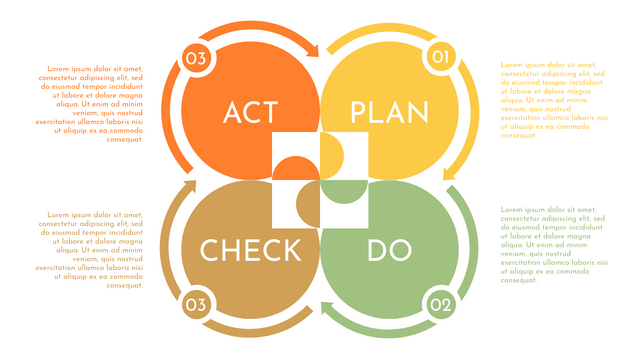

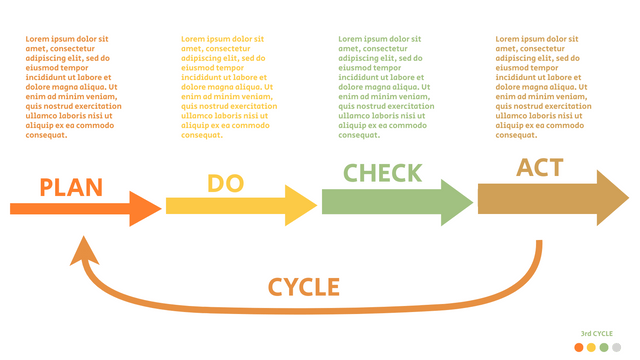

A PDCA cycle based on the scientific method of proposing a change in a process, implementing the change, measuring the results, and taking appropriate action. It also is known as the Deming Cycle or Deming Wheel after W. Edwards Deming, who introduced the concept in Japan in the 1950s.

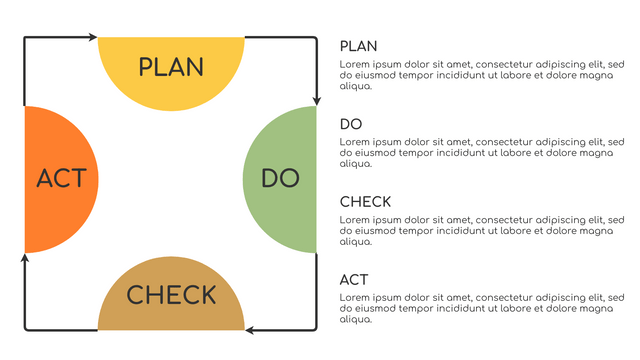

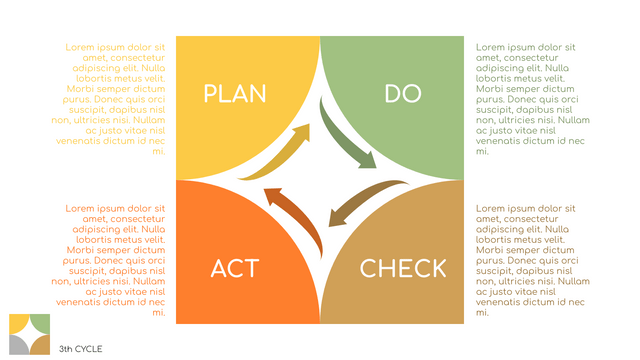

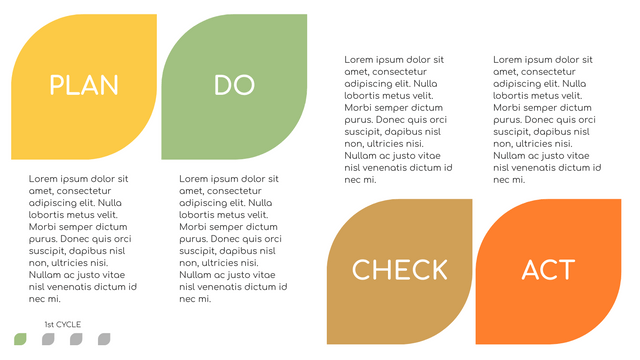

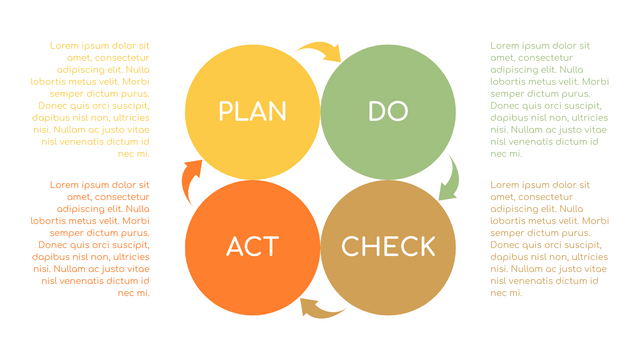

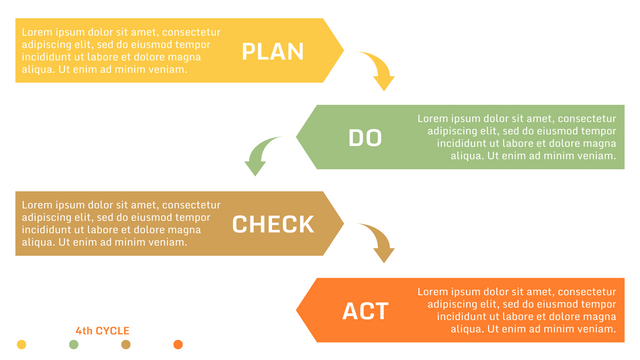

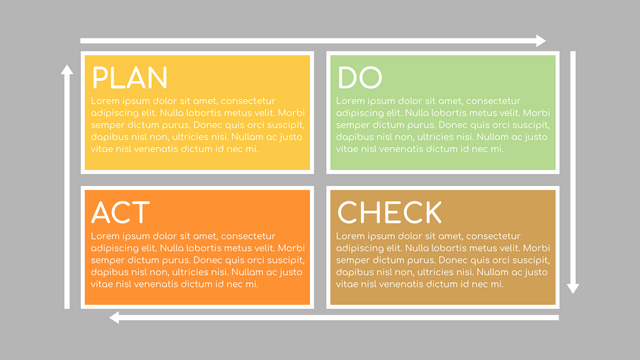

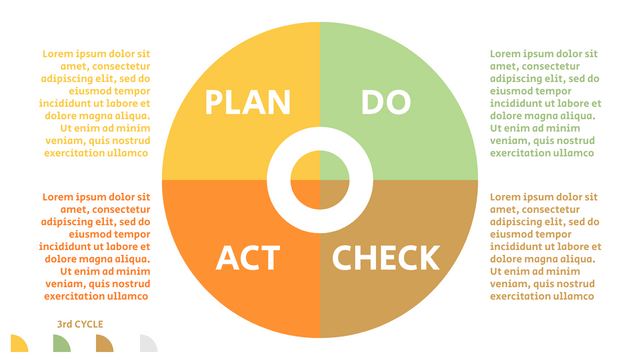

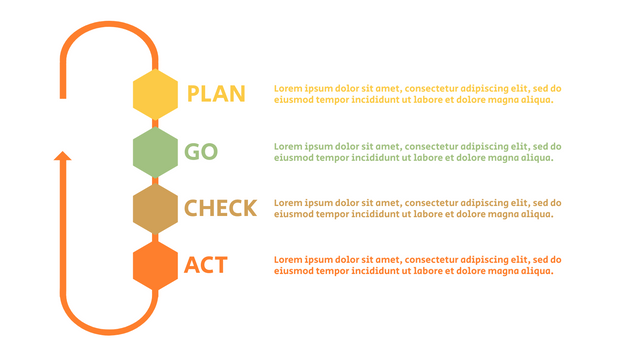

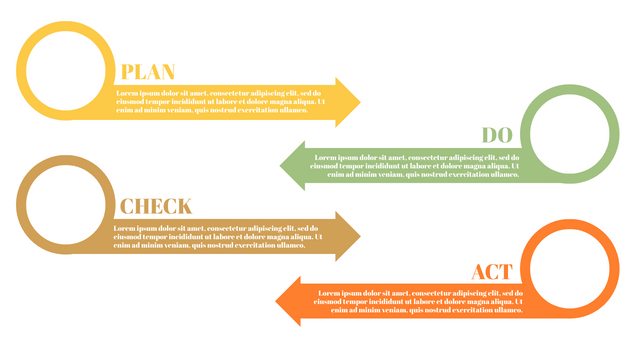

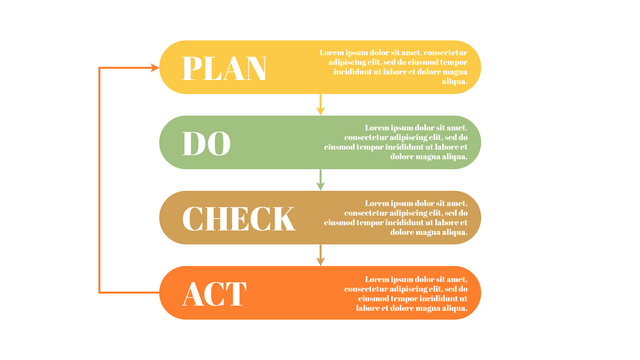

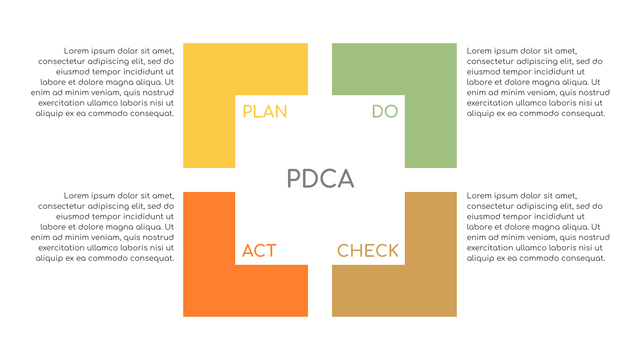

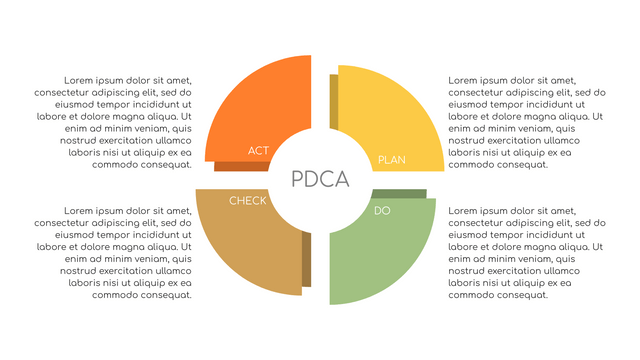

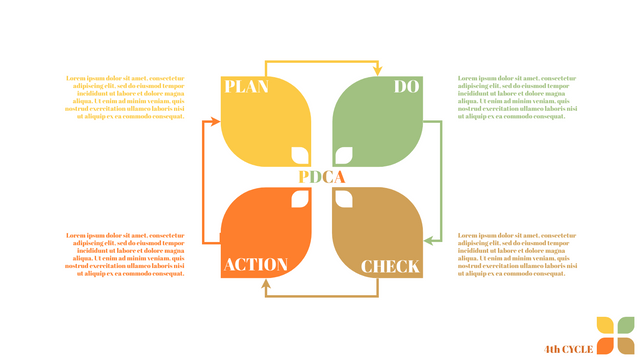

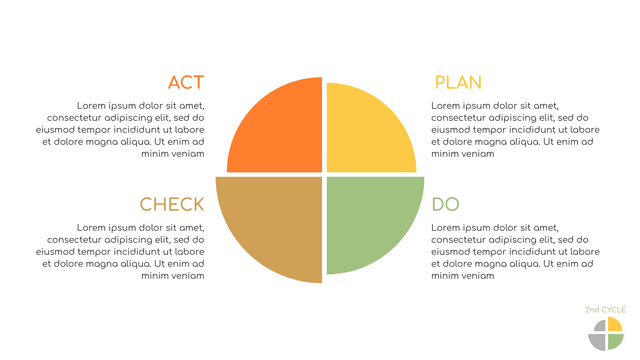

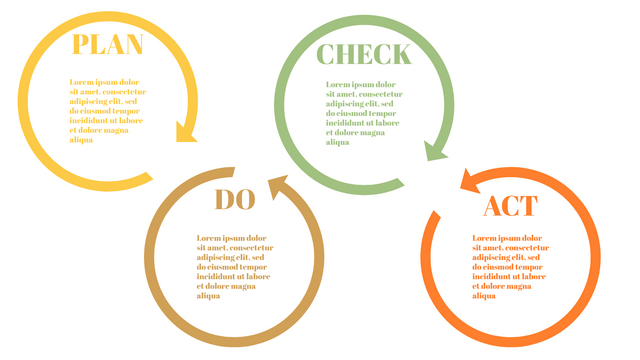

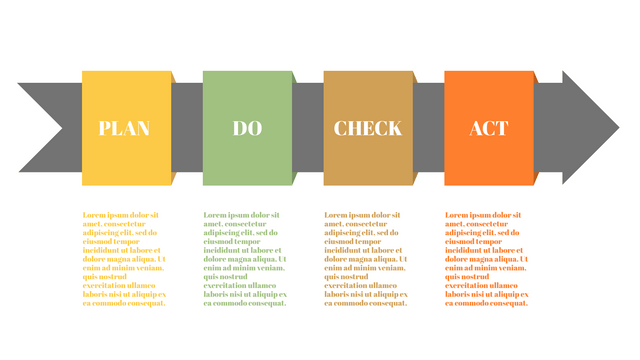

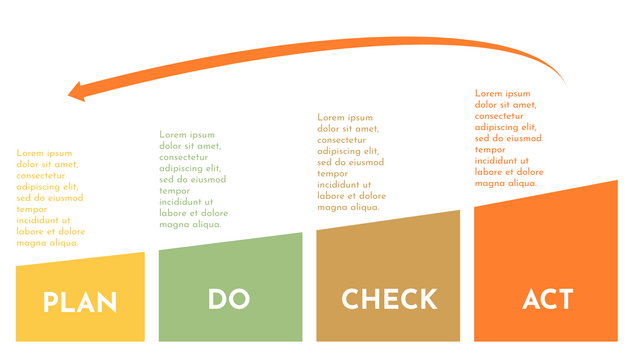

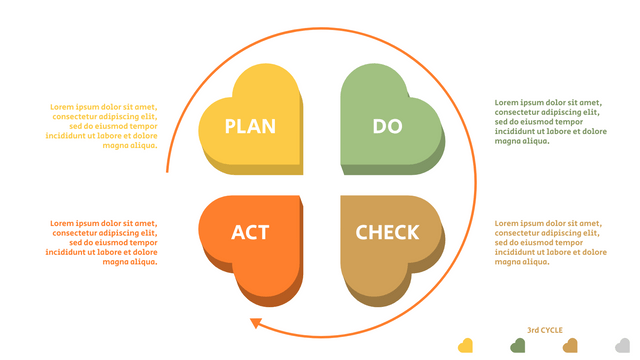

PDCA cycle is a four stage model providing a framework for developing, testing and implementing changes leading to quality improvement. The meaning of PDCA is as follows:

P (PLAN) - plan;

D (Do) - implementation;

C (Check) - inspection;

A (ACT) - action, processing the results of the summary inspection, and affirming successful experience Appropriate promotion and standardization; the lessons of failure are summarized, and the unresolved problems are put into the next PDCA cycle.

More than 20 years ago, the Japanese Federation of scientists and engineers (JFSE) expanded the PDCA to seven steps. PDCA cycle cane be corresponded to seven steps as follows:

Select and describe problem.

Study present system.

Identify possible causes.

Plan and implement solution.

Evaluate effects.

Standardize solution.

Reflect on process and develop future plans