Where did PDCA come From?

The PDCA Cycle is also known as the Shewhart or Deming Cycle, names that give recognition to its authors. Walter Shewhart was the founder of the system in the 1920s, but it was only in the 1950s that the model became popular, particularly in Japan, thanks to the American Professor. William Deming.

Initially, the PDCA cycle was developed to be applied in the administration of quality management, being a recommended method for the continuous improvement of quality, but its use was improved and today PDCA is one of the main tools for the understanding of the administrative process and for problem solving. The method underwent several changes during its more than 90 years of existence and can be adapted to be used in any type of company, regardless of its size or focus.

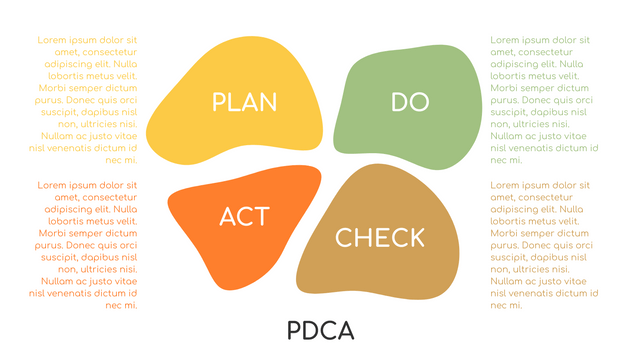

What is PDCA?

The PDCA cycle is a common tool used by enterprises to continuously improve processes and solve problems that are not easily discoverable. Often, these problems have also gone through several failed attempts to resolve them. The PDCA cycle helps accelerate and improve the company's activities by identifying problems, causes, and possible solutions.

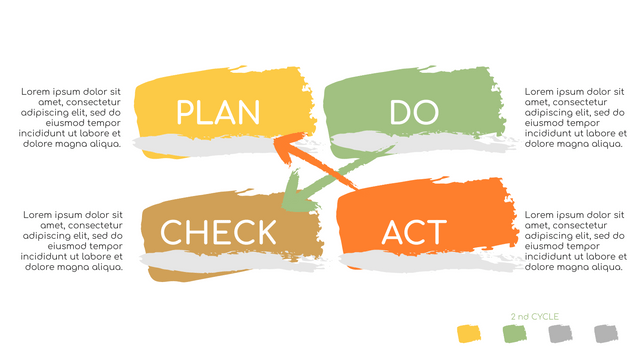

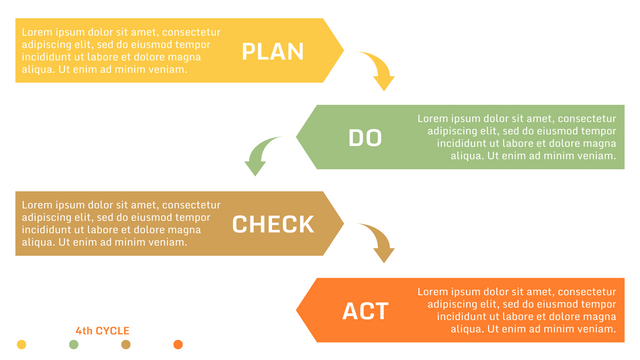

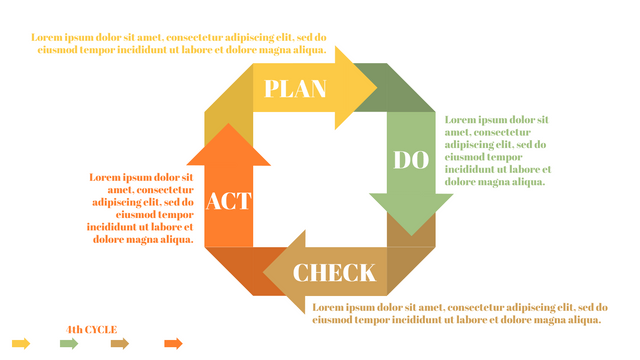

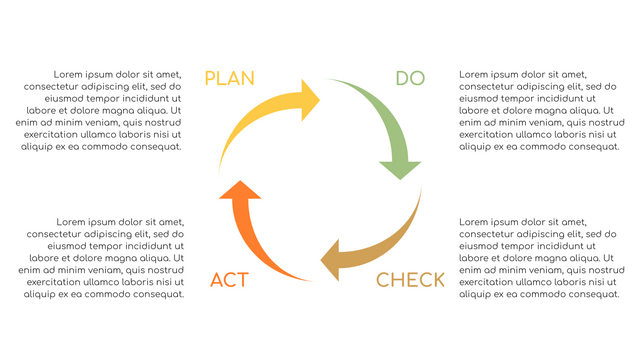

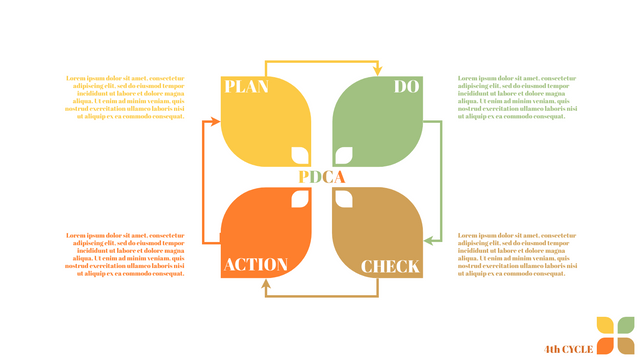

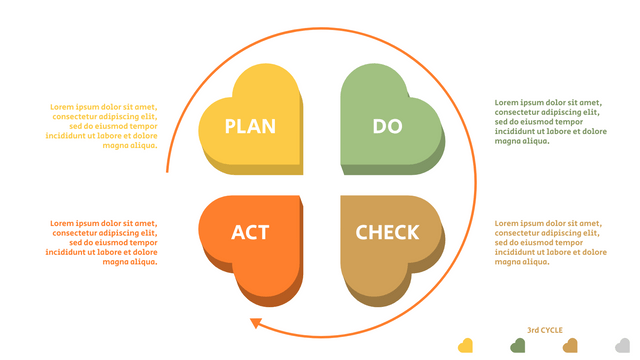

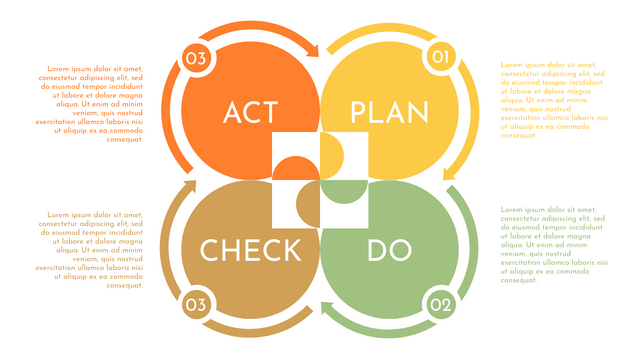

It's an iterative process that leads to continuous improvement and experience over time. Therefore, PDCA can be said to be a positive improvement cycle, providing an improvement result each time, providing a result for further improvement in the next cycle, making PDCA a a way to continuously solve problems and achieve greater success.

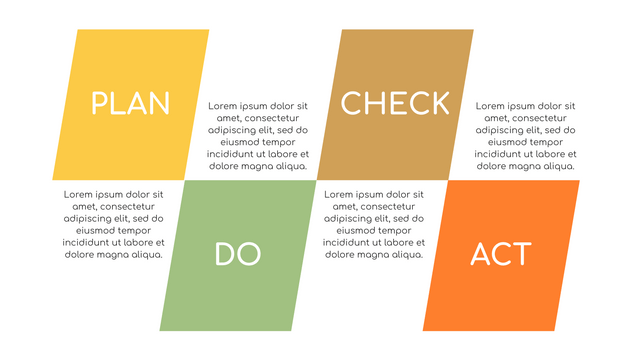

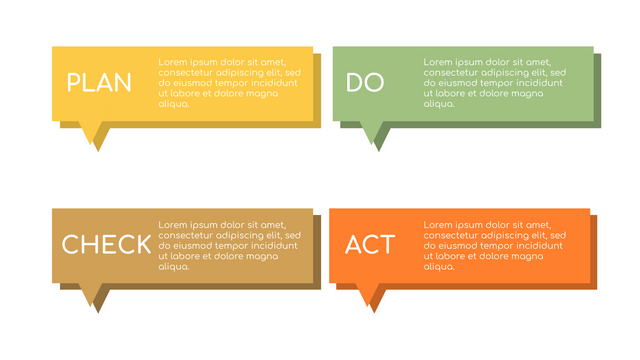

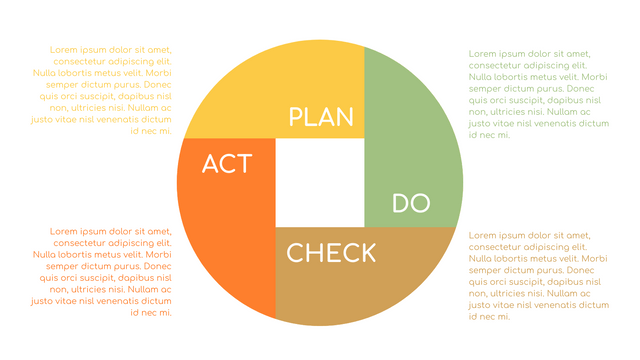

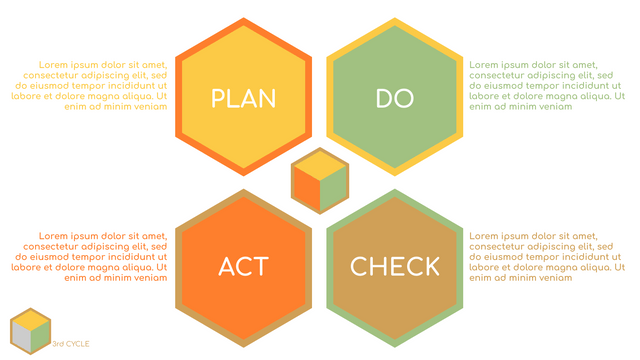

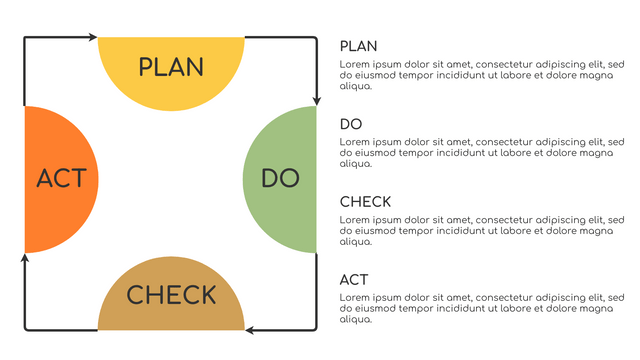

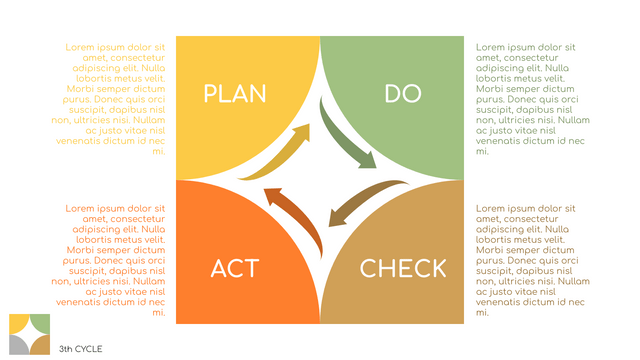

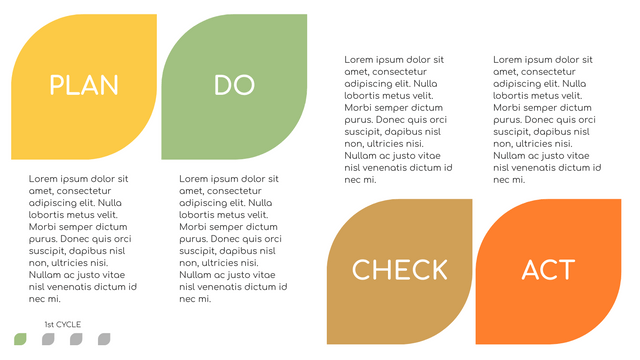

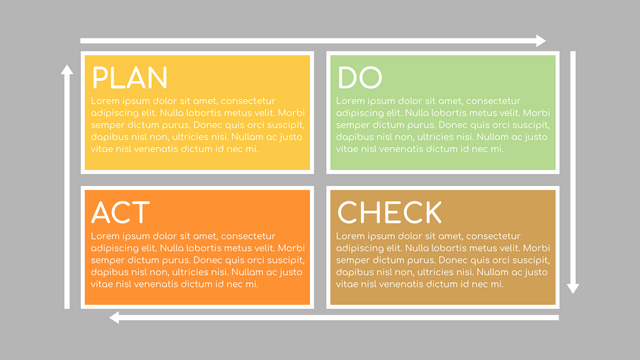

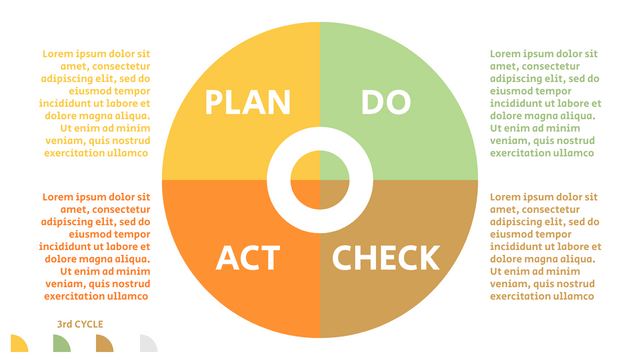

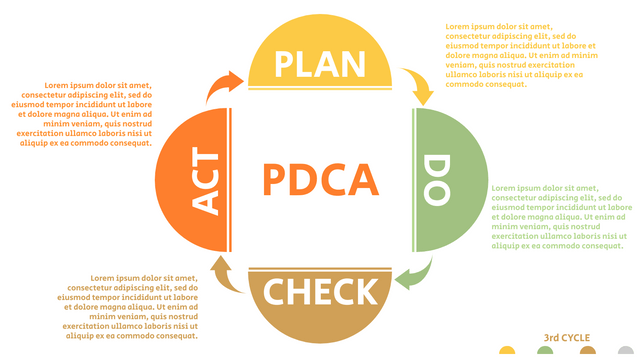

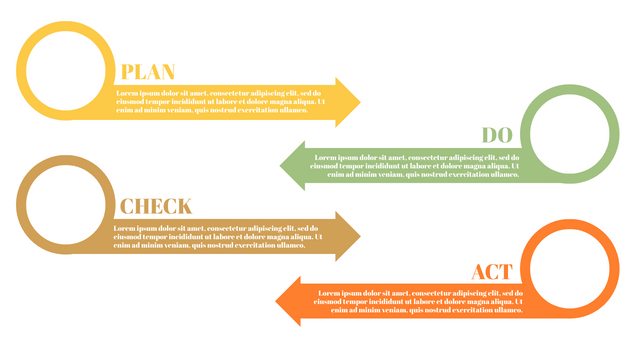

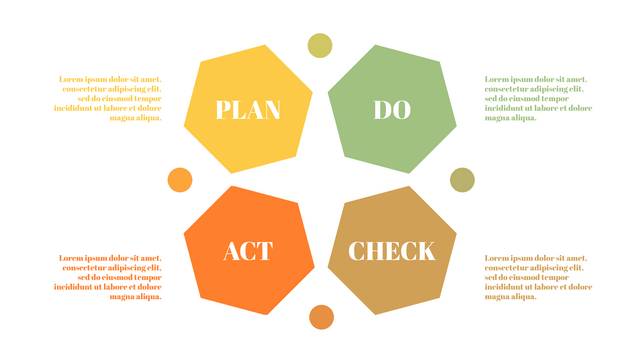

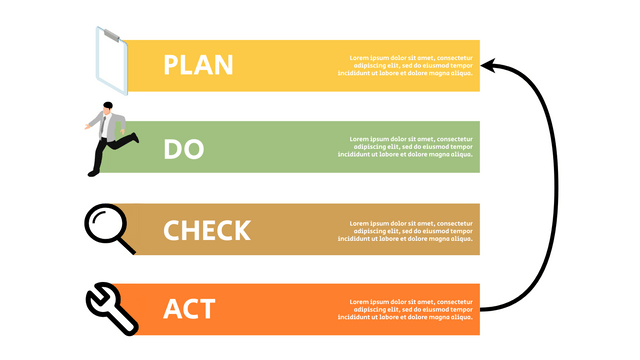

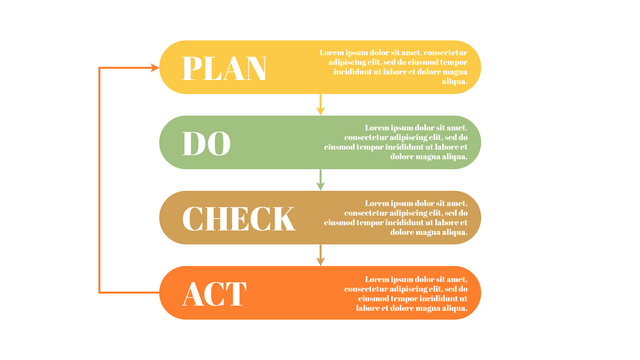

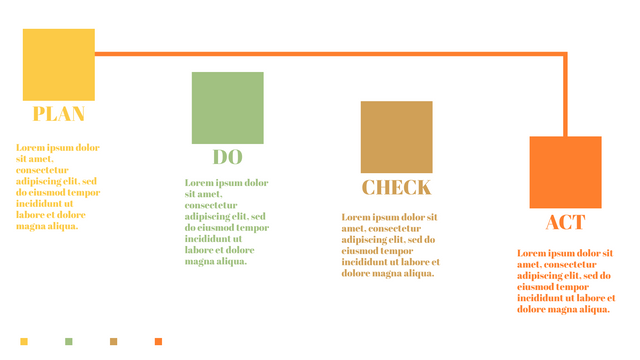

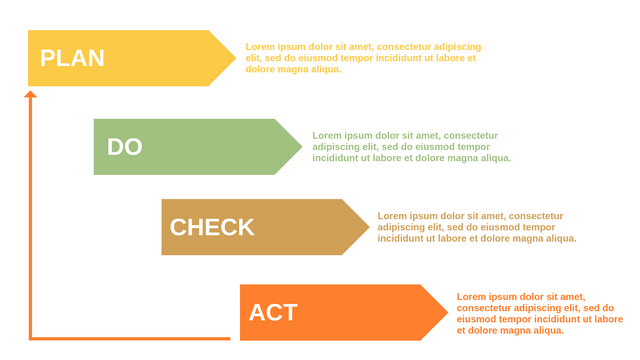

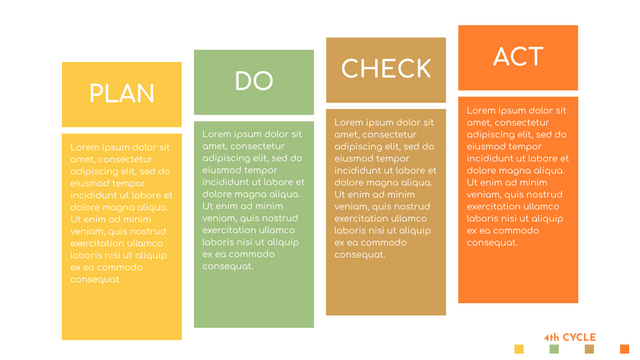

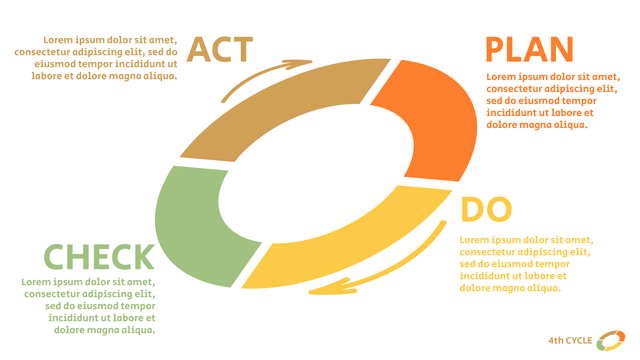

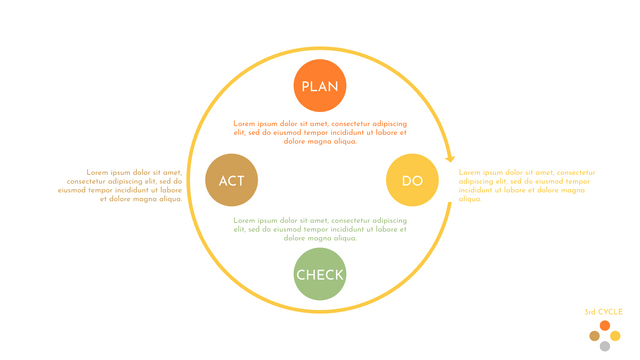

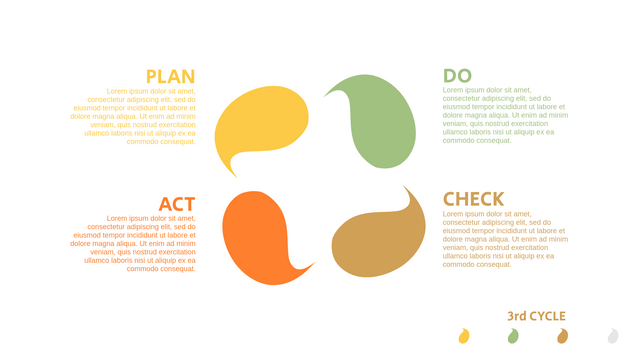

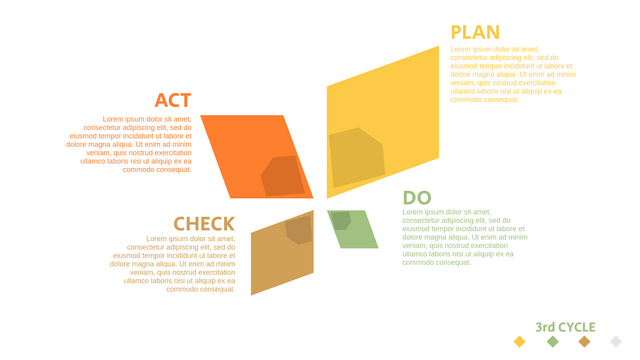

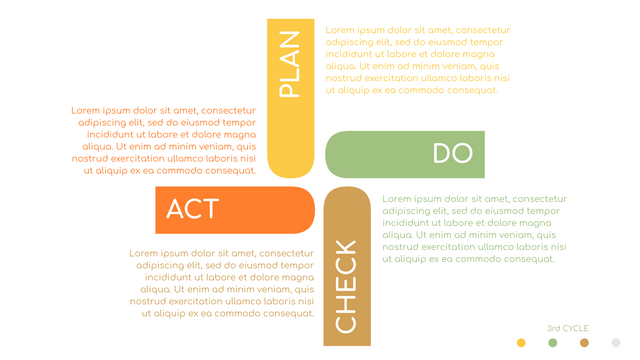

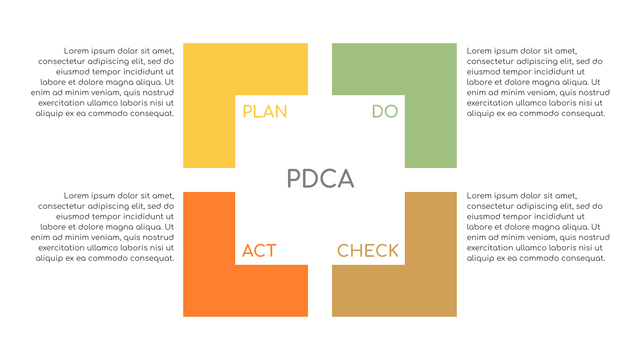

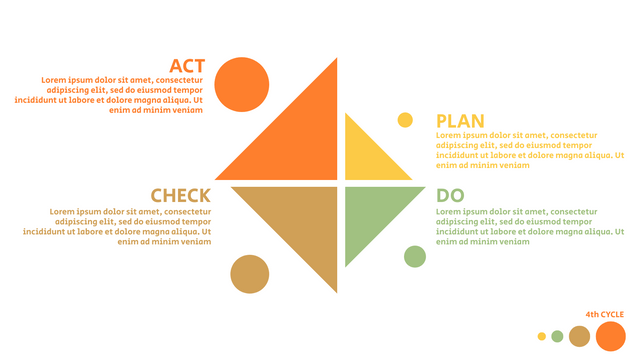

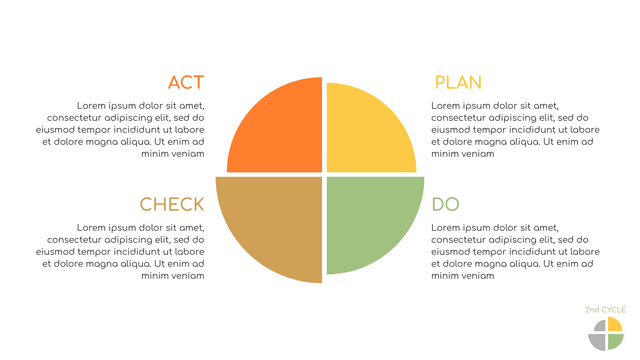

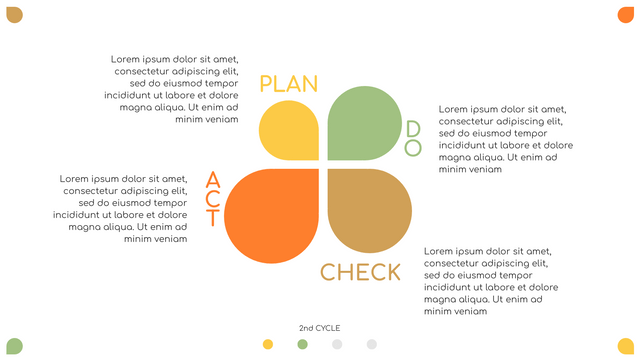

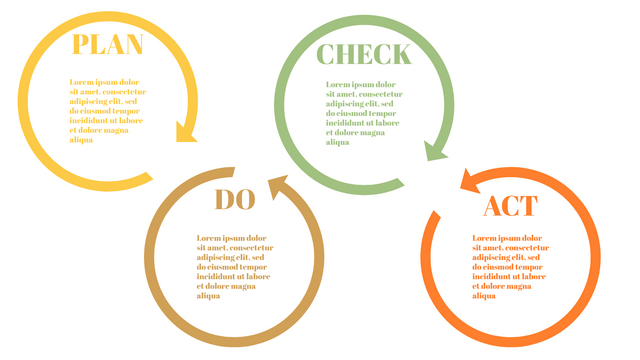

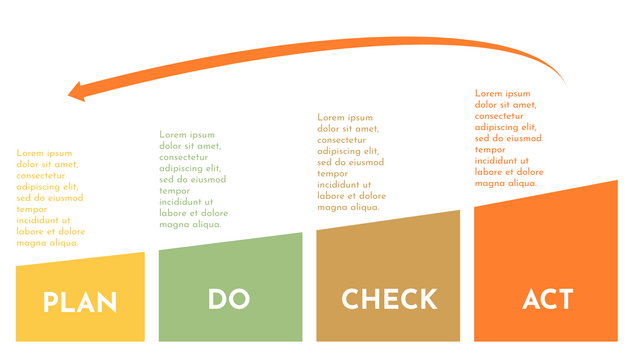

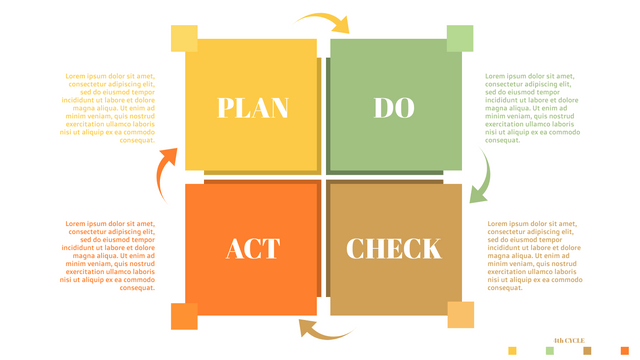

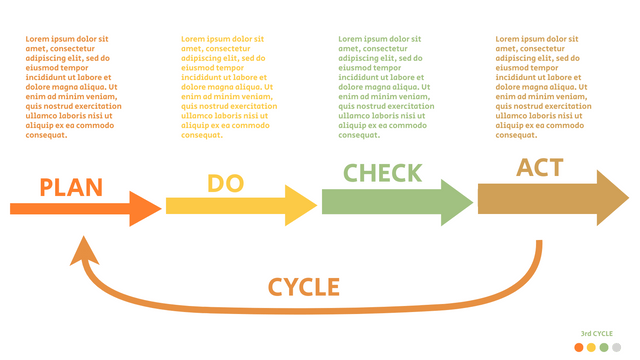

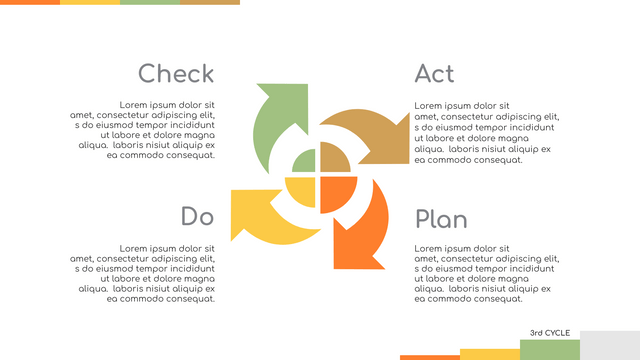

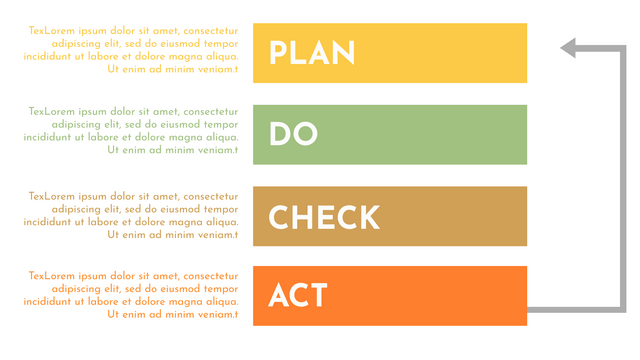

The 4 Stage Process

The PDCA Cycle provides a simple and effective approach for solving problems and managing change. It enables businesses to develop hypotheses about what needs to change, test these hypotheses in a continuous feedback loop, and gain valuable learning and knowledge. It promotes testing improvements on a small scale before updating company-wide procedures and work methods.

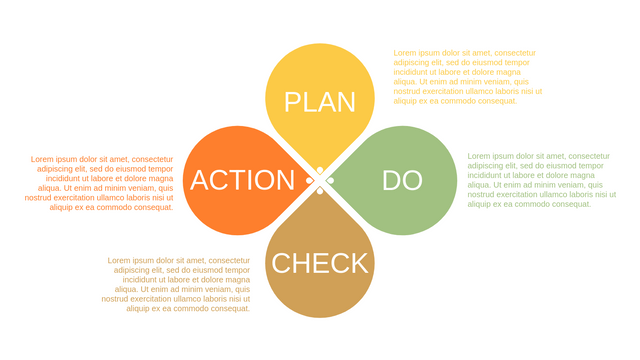

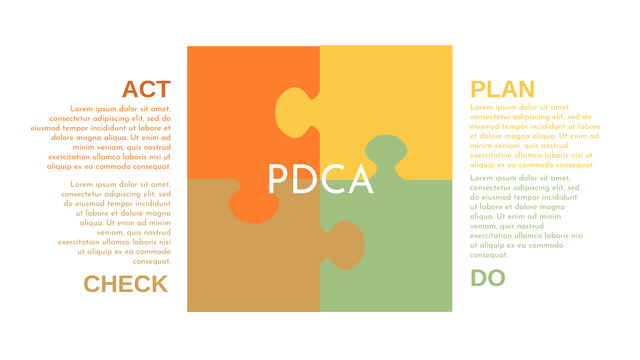

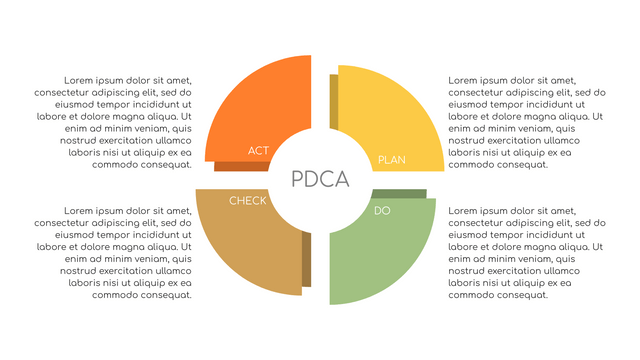

PDCA (Plan-Do-Check-Act) is an iterative, four-stage approach for continually improving processes, products or services, and for resolving problems.

Plan - Identify the problem, collect relevant data, understand the root cause of the problem, develop hypotheses about what the problem might be, and decide which one to test.

Do - develop and implement solutions; Determine measures to measure their effectiveness, test potential solutions, and measure results.

Check - Confirm results by comparing before and after data. Study the results, measure the validity, and determine whether the hypothesis is supported.

Act - Record results, inform others of process changes, and make recommendations for future PDCA cycles. If the solution is successful, implement it. If not, the next problem is dealt with and the PDCA cycle is repeated again.