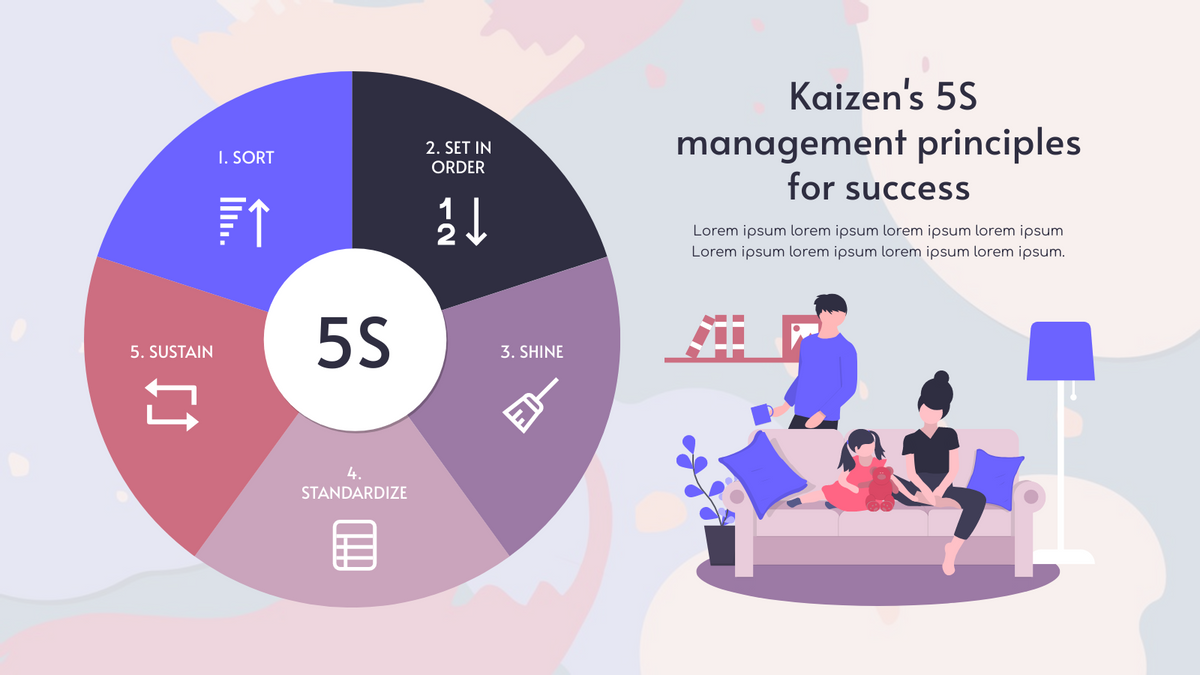

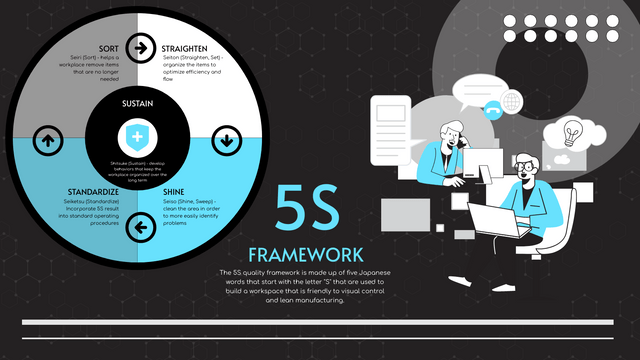

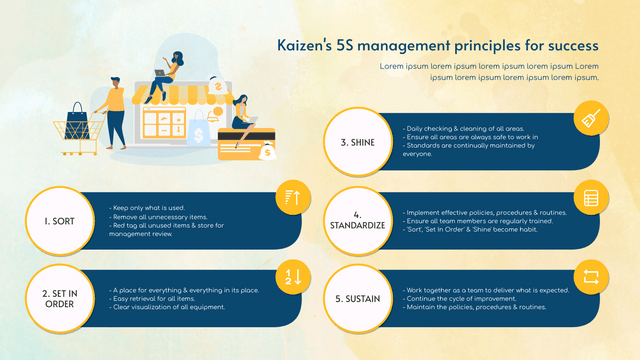

Kaizen's 5S Principles

Originating in Japan, 5S (also known as 5S Methodology, 5S System, and 5S framework) refers to the effective management of production factors such as personnel, machinery, materials and methods on the production site. It is a unique management method of Japanese enterprises.

5S is a workplace organization method that uses a list of five Japanese words:

seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾).

These have been translated as "sort", "set in order", "shine", "standardize" and "sustain".

Meaning of the 5S

Sort (seiri 整理) - Seiri is sorting through all items in a location and removing all unnecessary items from the location.

Set in order (seiton 整頓) - Seiton is putting all necessary items in the optimal place for fulfilling their function in the workplace.

Shine (seiso 清掃) - Seiso is sweeping or cleaning and inspecting the workplace, tools and machinery on a regular basis.

Standardize (seiketsu 清潔) - Seiketsu is to standardize the processes used to sort, order and clean the workplace.

Sustain/self-discipline (shitsuke しつけ) - Shitsuke or sustain is the developed processes by self-discipline of the workers. Also translates as "do without being told".

Toyota’s 5S Approach

After the Second World War, Japanese enterprises rapidly improved product quality and established the status of an economic power through the implementation of 5S. Under the initiative of Toyota, they established a corporate image, reduced costs, produced on time, safely and highly standardized. With the development of the world economy, 5S has become the trend of continuous development of factory management.

Here are the benefits of 5S approach:

improve the corporate image

improve production efficiency

improve inventory turnover

reduce failures, ensure quality

strengthen safety, reduce safety risks

develop the habit of saving, reduce production costs

shorten the operation cycle, ensure delivery

improve the spirit of the enterprise, form a good corporate culture

Kaizen's 5S Principles Template

Here is a Kaizen's 5S Principles template created with Visual Paradigm's online strategic analysis tool. You can customize this template by modifying the text, color and font, and use it in your presentations and reports.