PDCA (also known as Deming Cycle) was made popular by W. Edwards Deming which is an iterative four-step (Plan-Do-Check-Act) management method used in business for the control and continuous improvement of processes and products. It can be used and reused for almost any activity within a company, meaning the company is constantly reviewing its practices and processes and therefore continuously improving performance and productivity.

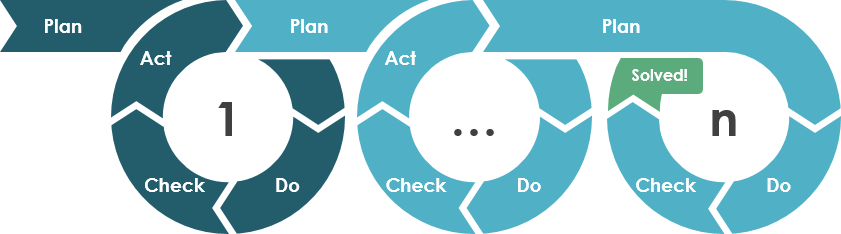

The fundamental principle of the scientific method and PDCA is iteration – once a hypothesis is confirmed (or negated), executing the cycle again will extend the knowledge further. Repeating the PDCA cycle can bring its users closer to the goal, usually a perfect operation and output. Thus, using the Plan Do Check Act (PDCA) method is like climbing a hill: it starts out easy but gets harder the higher up you go.

PDCA – Four Step Management Method

PDCA is an iterative, four-stage approach for continually improving processes, products or services, and resolving problems. The four steps can be repeated over and over as part of a never-ending cycle of continual learning and improvement. The purpose of the repetitive cycle is to keep extending knowledge further to help improve the process and achieve the desired goal by systematically testing possible solutions, assessing the results, and implementing the ones that have shown to work.

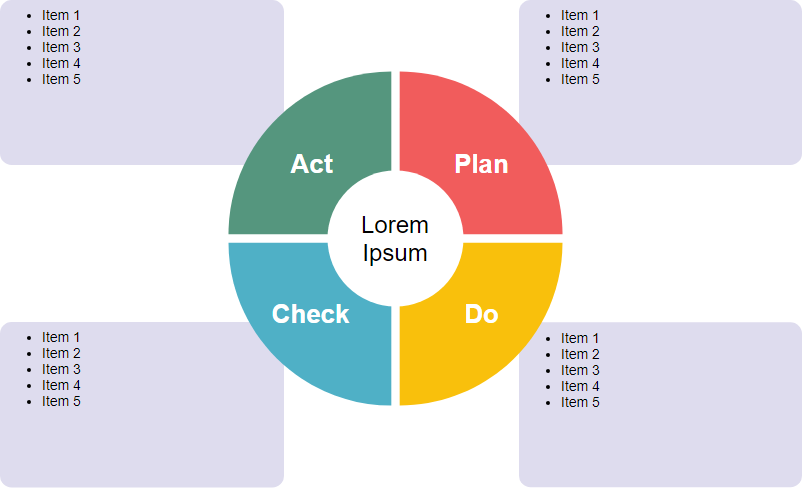

The four steps in the iterative cycle are as follows:

Plan: establish the objectives and goals, identify the problem and gather relevant data. Develop hypotheses about what the issues may be and select certain ones for further testing. A detailed description should be clearly specified.

Do: Execute and implement plans that are set from the previous stage. It’s ideal to keep the stakeholders informed during this process. Decide upon a measurement to benchmark its effectiveness. Test for potential solutions and evaluate the results.

Check: verify the results by data comparison. Make a note of all variations, defects, obstacles, issues or challenges that occurred. Identify the root causes of the problems.

Act: apply the fix to any defects and make it comply with the specifications. Develop preventive actions to use against all the root causes identified. Make sure to document the results and inform all regarding the process changes. Create a list of recommendations for the future PDCA cycles. If the solution was successful then implement it to take effect. On the other hand, if the solution failed then repeat the PDCA cycle again.

PDCA Process is widely-used by different Industries for the following purposes:

- When defining a process.

- When implementing a change.

- When looking for continuous improvement.

- When creating a new product or service

For example, Toyota and other lean manufacturing companies propose that an engaged, problem-solving workforce using PDCA in a culture of critical thinking is better able to innovate and stay ahead of the competition through rigorous problem solving and the subsequent innovations.