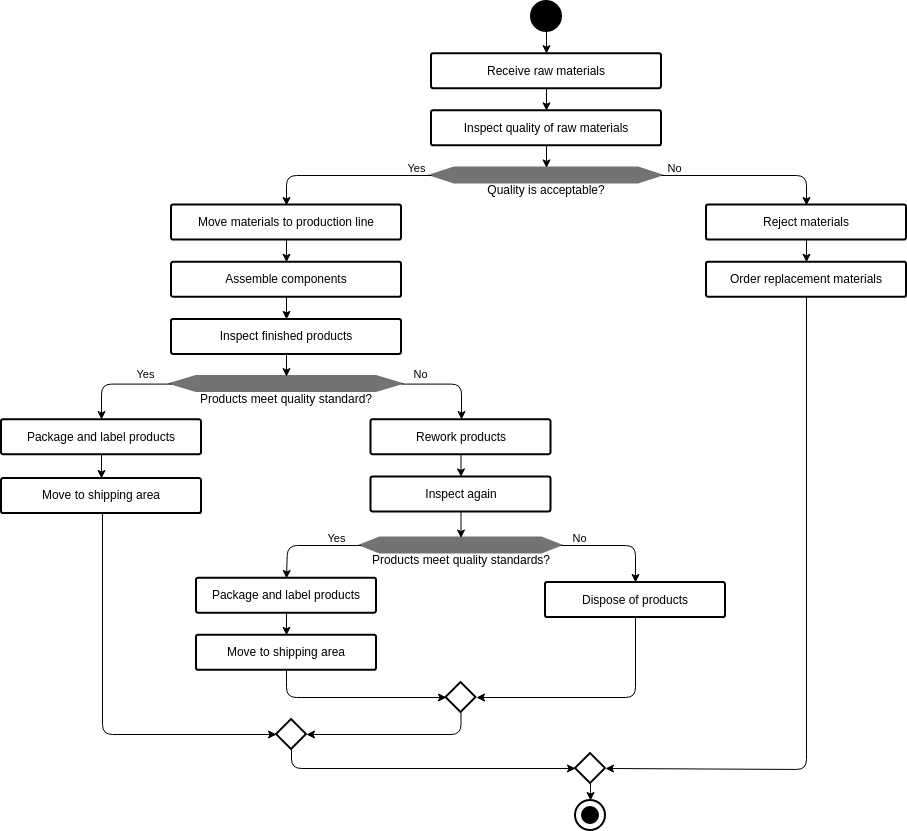

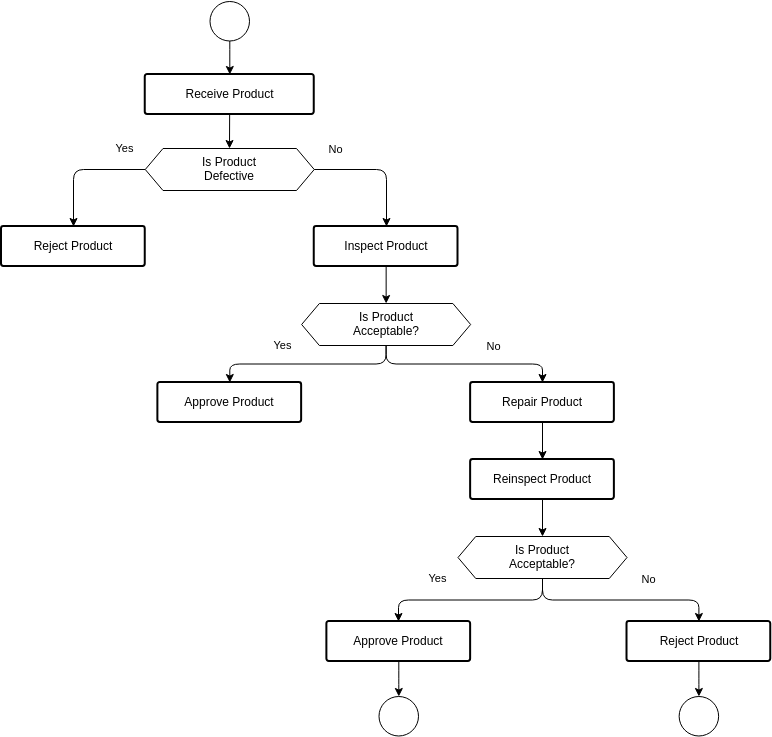

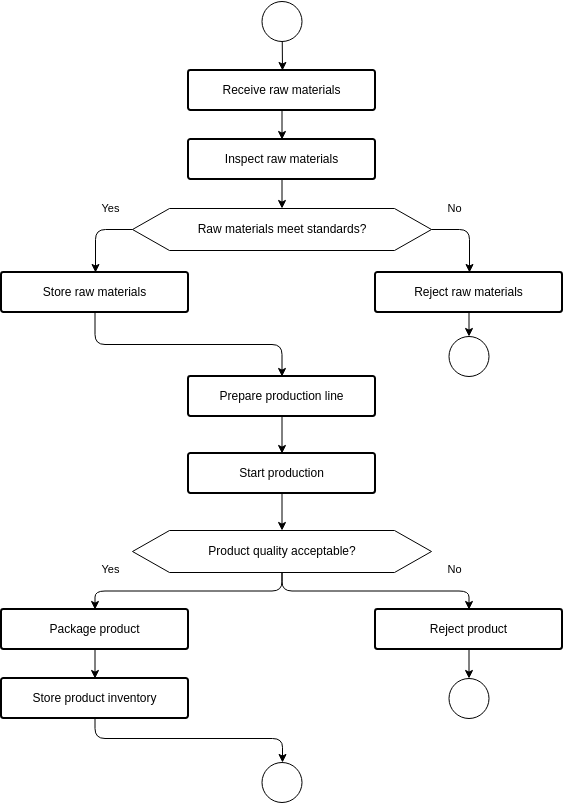

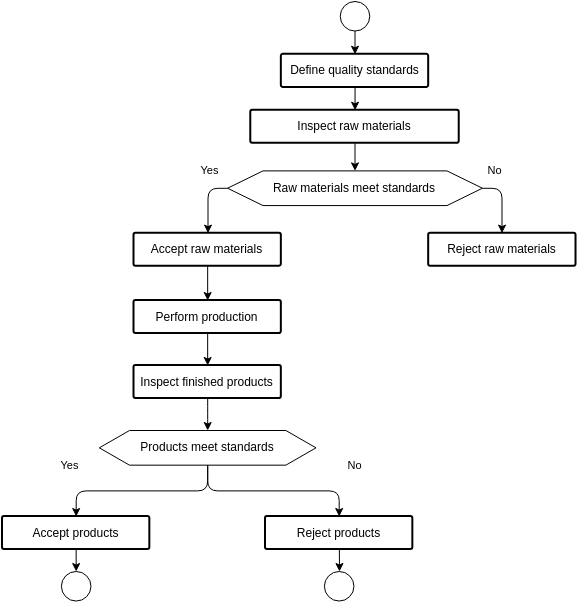

The Quality Control Process Flowchart outlines the steps involved in the production of a product with a focus on quality control. The first step in the process is to receive raw materials. This step involves verifying that the materials received match the order placed and inspecting the quality of the materials. Any discrepancies are reported to the supplier, and any quality issues are addressed before moving the materials to the production line.

The next step is to move the raw materials to the production line. This step involves transporting the raw materials to the production area and ensuring that they are stored in the correct location. Once the materials are in the production area, the components are assembled as per the production plan. This step involves following the production plan to assemble the components into finished products while ensuring that quality is maintained throughout the process.

The assembled products are then inspected for quality. This step involves verifying that the components have been assembled correctly and that the finished products meet the required quality standards. If any defects are found, the products are reworked to correct the issue. Once the defects have been corrected, the finished products are inspected again to ensure that they meet the required quality standards.

After the products have been inspected and approved, they are packaged and labeled. This step involves packaging the finished products in the appropriate packaging material and labeling them according to the product specifications. Once the products have been packaged and labeled, they are moved to the shipping area. This step involves transporting the finished products to the shipping area where they are prepared for shipment to customers while ensuring that their quality is maintained.

Overall, the Quality Control Process Flowchart outlines a clear and efficient process for the production of high-quality products. By following a standardized process with a focus on quality control, the production team can ensure that products are of consistent quality and meet the required quality standards. The flowchart can be used as a training resource for new staff members, ensuring that they are familiar with the correct procedures to follow and the importance of maintaining product quality. Additionally, the flowchart can help to identify any quality issues in the production process, allowing for improvements to be made to increase quality and customer satisfaction.

Benefits of creating this flowchart

Creating a Quality Control Process Flowchart has several benefits for a company. Firstly, it helps to standardize the process of production with a focus on quality control. By following a standardized process, the production team can ensure that products consistently meet the required quality standards. This helps to reduce the likelihood of customer complaints and product recalls due to quality issues. The flowchart can also serve as a reference tool for staff members, allowing them to quickly access information about the correct procedures to follow and the importance of maintaining product quality. This helps to reduce the learning curve for new staff members and ensures that everyone is following the same process.

Secondly, the flowchart can help to improve the efficiency of the production process with a focus on quality control. By clearly outlining the steps involved in the production process and highlighting the importance of quality control, the flowchart can help to identify any bottlenecks or inefficiencies in the process that could impact product quality. This information can then be used to make improvements to the process, such as automating certain steps or reallocating staff resources to ensure that quality is maintained throughout the production process. Improving the efficiency of the production process with a focus on quality control can help to reduce costs, improve customer satisfaction, and increase productivity.

Searching for some flowchart templates? Go to Visual Paradigm Online and select some designs for customization now!