SIPOC is a tool that summarizes the inputs and outputs of one or more processes in table form. It is widely used in process design and improvement initiatives to identify relevant information before starting a project. SIPOC was in use at least as early as the total quality management programs of the late 1980s and continues to be used today in Six Sigma, lean manufacturing, and business process management.

What is SIPOC?

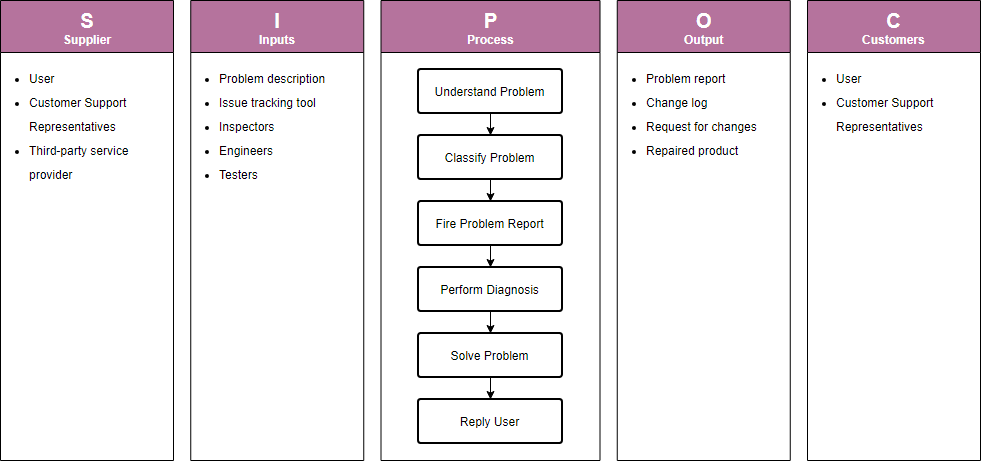

The acronym SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customer. Using information from these five areas creates a process map that gives a high-level overview of a Six Sigma project. To create a SIPOC diagram, you have to specify the five main activities of the process and identify the potential suppliers, inputs, outputs, and customers.

So, what do the five areas of the diagram include? Here are short explanations in the context of a lemonade stand example:

- Supplier – The provider of inputs into a process, i.e. Grocery store, home store, customer requests

- Input – Materials, information and other resources needed to complete a process, i.e. Lemon juice, water, sugar, ice, cups, stirring spoon, large pitcher, wood from home store, money jar, a busy pedestrian area, people to operate stand

- Process – Structured steps used to convert inputs into outputs, i.e. Construct lemonade stand, combine ingredients to make lemonade in a pitcher, take customer orders, pour lemonade from pitcher to cup

- Outputs – Products or services resulting from the process, i.e. Chilled glass of lemonade, money placed in a jar

- Customer – Recipient of the outputs, i.e. Thirsty pedestrians

SIPOC Diagram at a Glance

- A high-level process map that defines the scope of a process and its inputs, outputs, suppliers, and customers.

- Represents the flow of the process and its key elements in a table format.

- Widely used in process design and improvement initiatives.

- It helps identify relevant information before starting a project.

How to Create a SIPOC Diagram?

A SIPOC map can be created quickly by drawing a table of five columns then title them respectively as suppliers, inputs, process, outputs, and customers. You can then add each of the SIPOC elements in the appropriate column.

Like process mapping, SIPOC is a team effort. Your team should include people with enough knowledge of the process.

Seven Steps for Development SIPOC

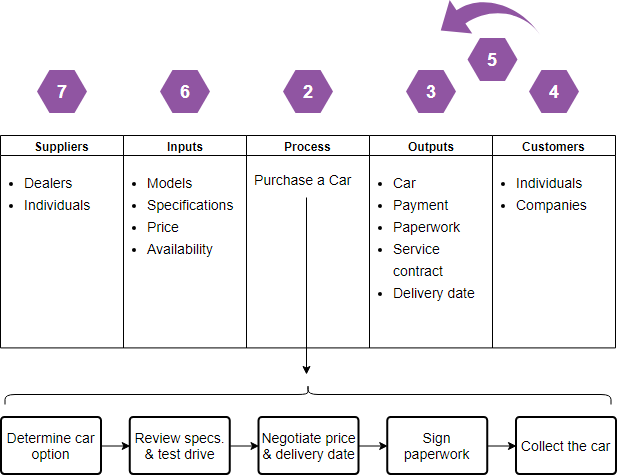

The following steps describe how to create a SIPOC map with your team in the context of “A Car Purchasing Process” example:

- Establish a name or title for the process for the SIPOC Diagram.

- Describe the top-level process steps of the process

- Fill out the Outputs section

- Who are the Customers? Who will benefit from this process? Who will be upset if this process doesn’t work as required?

- What are the Customers’ requirements? List the requirements for each of the Outputs

- What are the External Inputs to the “Process”? List the requirement described in the process for each of the inputs

- Who Supplies the Inputs?

SIPOC Template and SIPOC Example

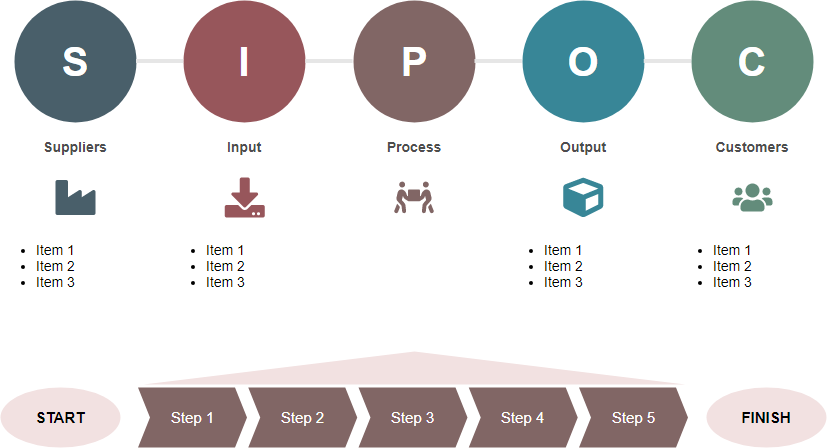

SIPOC Template

SIPOC Example