5S is a step-by-step method with which you can eliminate all waste that is caused by the way your workplace is organized, and build a culture of continuously improving efficiency and productivity. 5S was developed in Japan and was identified as one of the techniques that enabled Just in Time manufacturing.

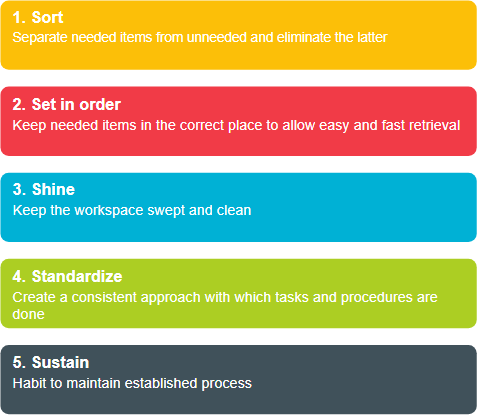

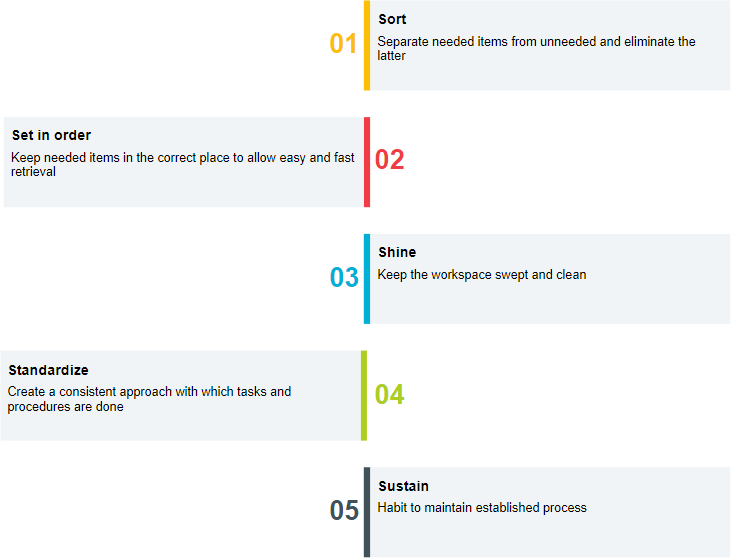

The 5S is done by Sorting (Seiri), Set in Order (Seiton), and Shining (Seiso) your workplace, and then Standardizing (Seiketsu) and Sustaining (Shitsuke) the results.

The 5S list is as follows:

1. Sort – Separating of the essential from the nonessential items

Goals

- Reduce time lost looking for an item by reducing the number of items.

- Reduce the chance of distraction by unnecessary items.

- Simplify inspection.

- Increase the amount of available, useful space.

- Increase safety by eliminating obstacles.

Implementation

- Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

- Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a ‘red tag area’ so that they are easy to remove later on.

- Keep the working floor clear of materials except for those that are in use to production.

2. Set In Order – Organizing the essential materials where everything has its place

Goal

- Make the workflow smooth and easy.

Implementation

- Arrange work stations in such a way that all tooling/equipment is nearby, in an easy to reach the spot and in a logical order adapted to the work performed. Place components according to their uses, with the frequently used components being nearest to the workplace.

- Arrange all necessary items so that they can be easily selected for use. Make it easy to find and pick up the necessary items.

- Assign fixed locations for items. Use clear labels, marks or hints so that items are easy to return to the correct location and so that it is easy to spot missing items.

3. Shine – Cleaning the work area

Goals

- Improves the production process efficiency and safety, reduces waste, prevents errors and defects.

- Keep the workplace safe and easy to work in.

- Keep the workplace clean and pleasing to work in.

- When in place, anyone not familiar with the environment must be able to detect any problems within 50 feet in 5 sec.

Implementation

- Clean the workplace and equipment daily, or at another appropriate (high frequency) cleaning interval.

- Inspect the workplace and equipment while cleaning.

4. Standardize: Establishing a system to maintain and make 5S a habit

Goal:

- Establish procedures and schedules to ensure the repetition of the first three ‘S’ practices.

Implementation:

- Develop a work structure that will support the new practices and make it part of the daily routine.

- Ensure everyone knows their responsibilities of performing the sorting, organizing, and cleaning.

- Use photos and visual controls to help keep everything as it should be.

- Review the status of 5S implementation regularly using audit checklists.

5. Sustain – Establishing a safe and sanitary work environment (Safety)

Goal

- Ensure that the 5S approach is followed.

Implementation

- Organize training sessions.

- Perform regular audits to ensure that all defined standards are being implemented and followed.

- Implement improvements whenever possible. Worker inputs can be very valuable for identifying improvements.

- When issues arise, identify their cause and implement the changes necessary to avoid recurrence.

The Purpose of 5S

The purpose of 5S is to eliminate wasted time, wasted space and wasted inventory. Implementing 5S raises product quality and improves work productivity, resulting in lower costs and higher efficiencies.

The 5S philosophy is:

“A place for everything and everything in its place,”

There are many benefits to implementing the 5S Methods into a work area on the production line or in the business office. To not only survive but thrive in business today, the cost must be controlled and waste must be avoided or eliminated. With the 5S method, the team can achieve the following:

- Teamwork improvement through everyone’s participation

- Identify Abnormalities

- Identify wastes and reduce the wastes

- Improve productivities

- Improve safety

5S Templates

Clean 5S template

Vertical 5S Template