PDCA is considered one of the most popular frameworks for continuous business process improvement. The PDCA cycle is best known as a business improvement model for organizing business processes and manufacturing. It was invented in the 1950s by Edward Deming, a statistician working in Japan. His PDCA cycle has become one of the pillars of Toyota's just-in-time production system. Over the past two decades, Toyota's systems have become one of the most successful demonstrations of lean manufacturing using PDCA; Details about Toyota's use of PDCA in Lean Methods can be found in Jeffrey Lake's book Toyota Way (2003).

According to Deming, you can apply PDCA for the following purposes:

Having a system in place for continuous quality improvement

Reducing defects through higher levels of quality uniformity

Understanding what quality should mean within context

What Does the Deming Cycle Mean?

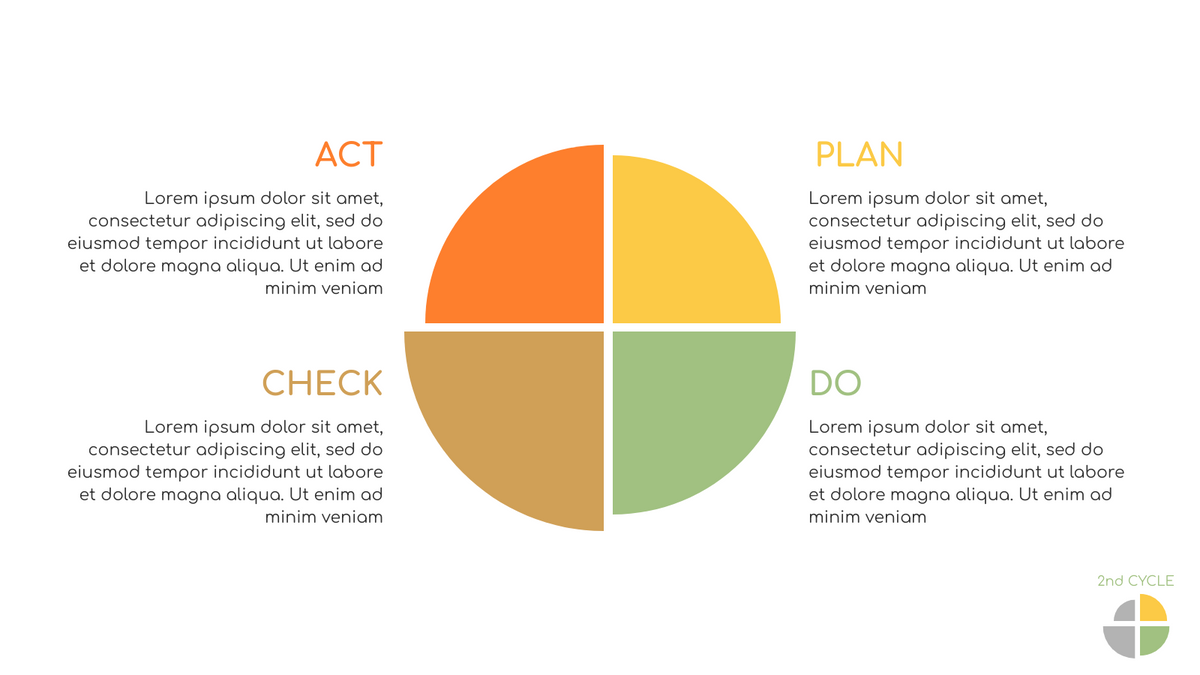

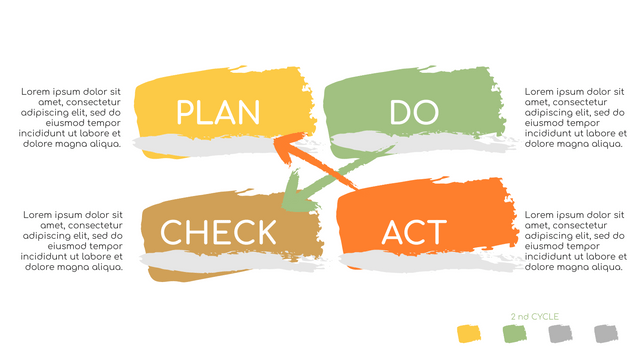

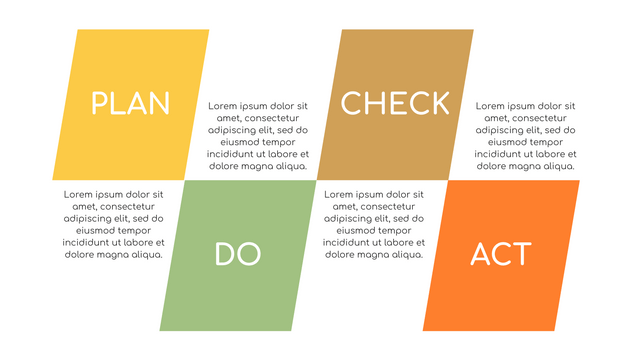

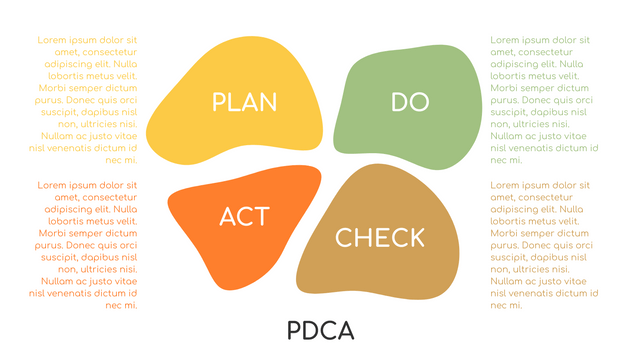

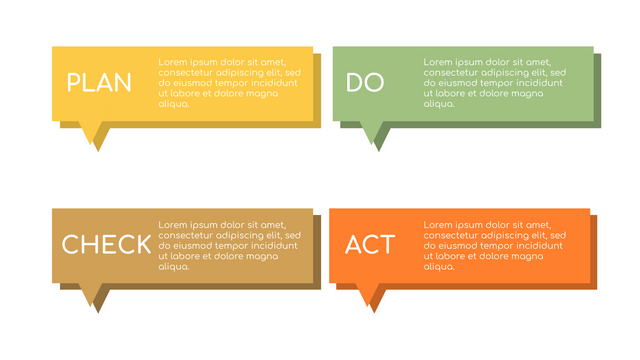

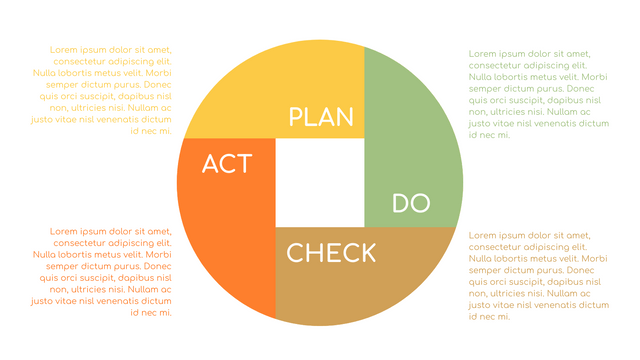

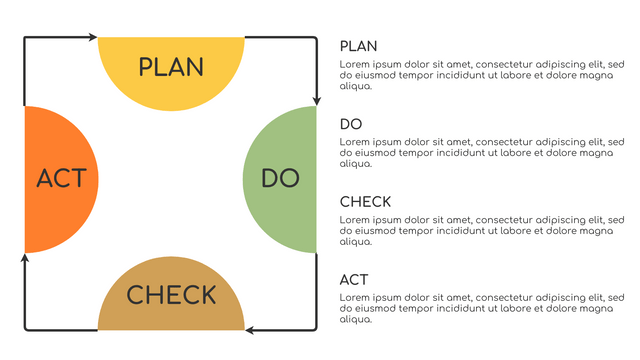

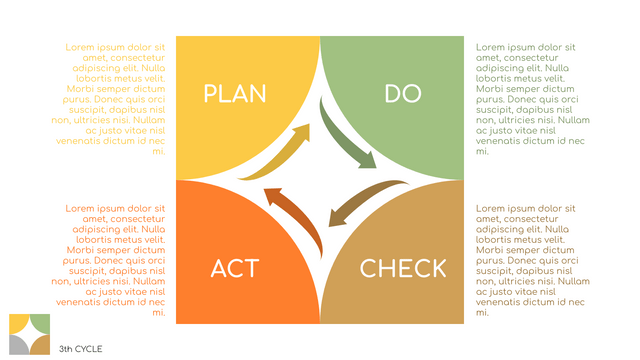

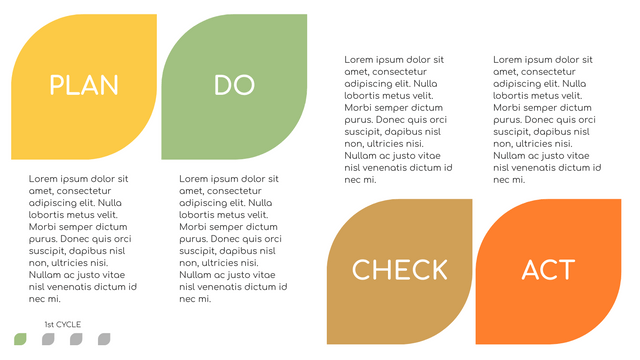

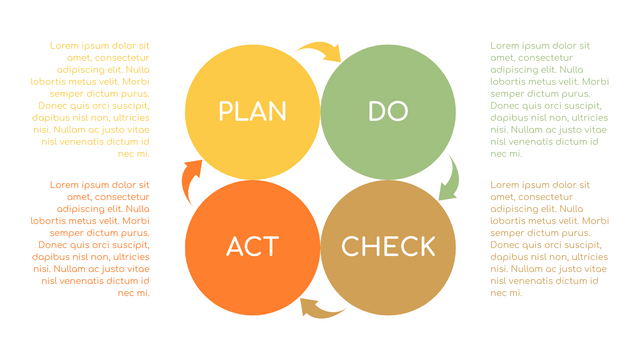

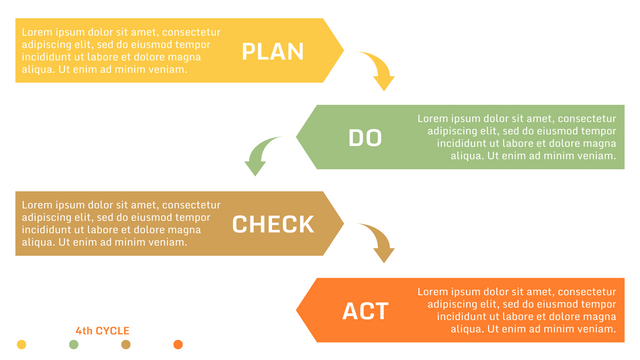

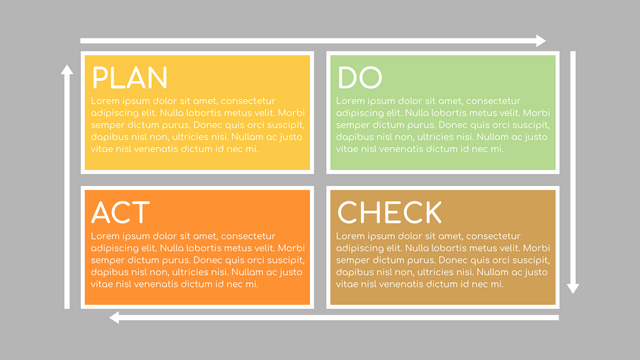

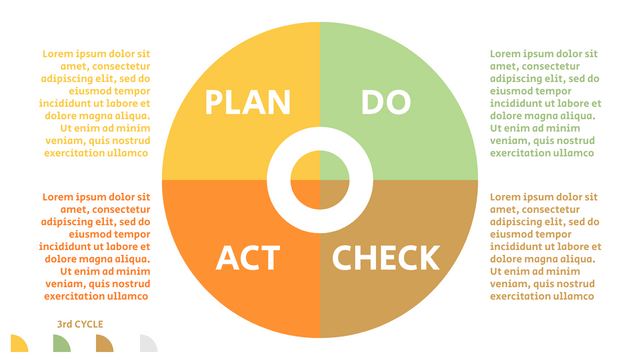

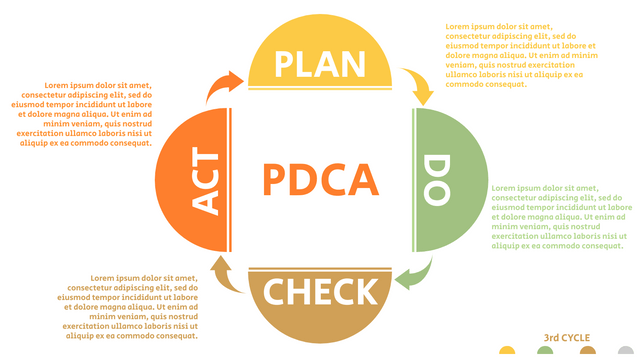

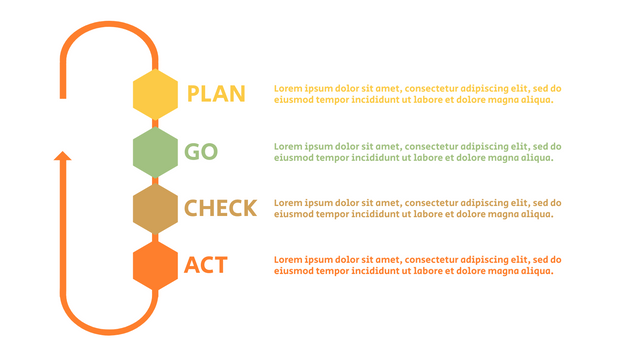

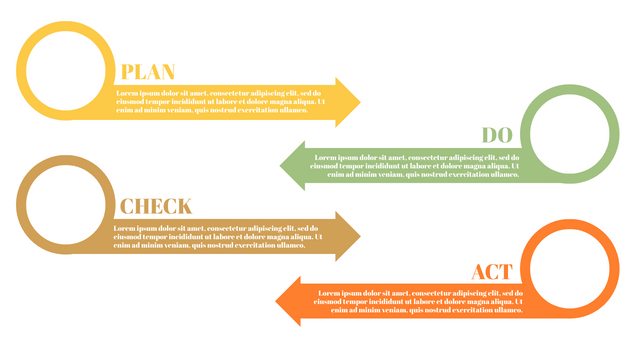

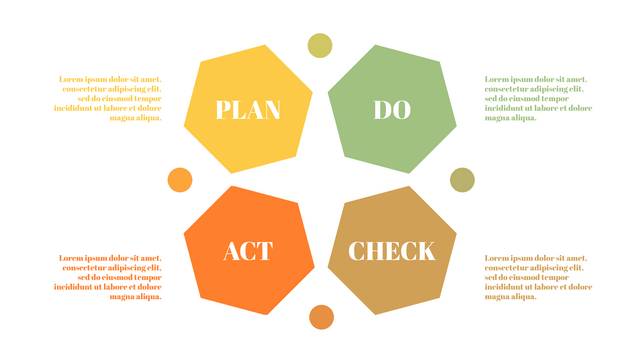

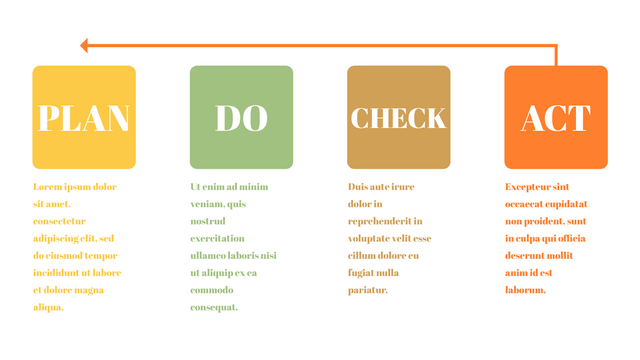

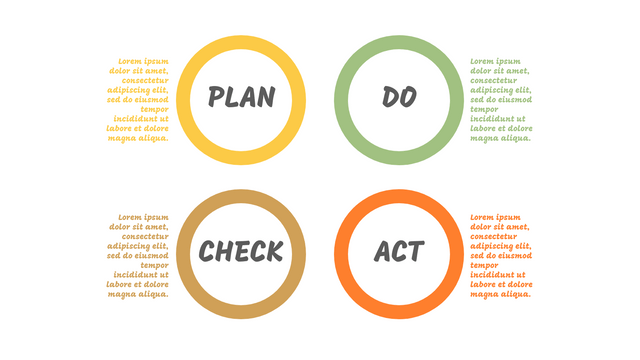

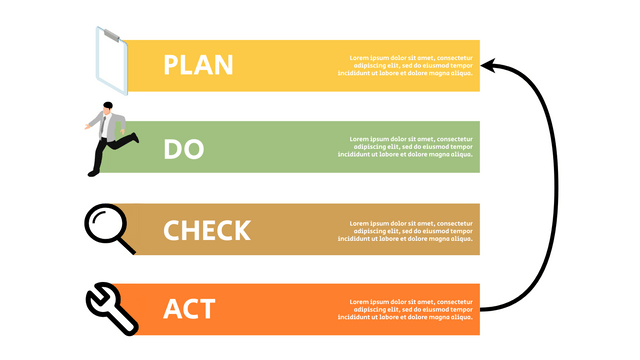

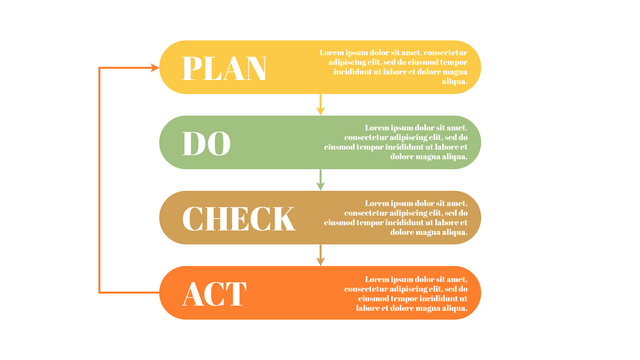

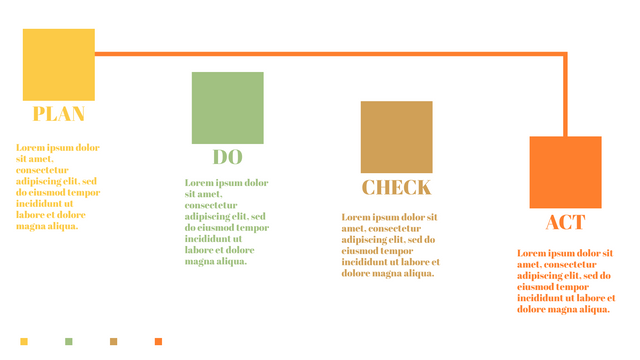

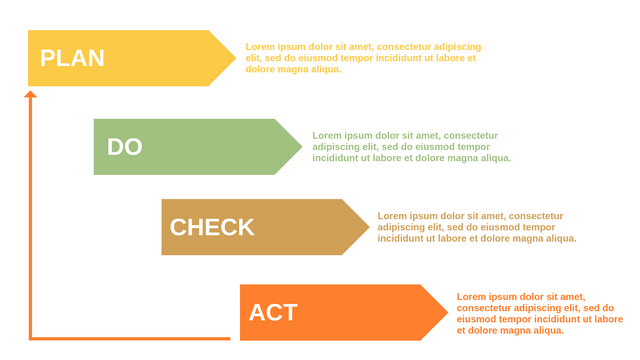

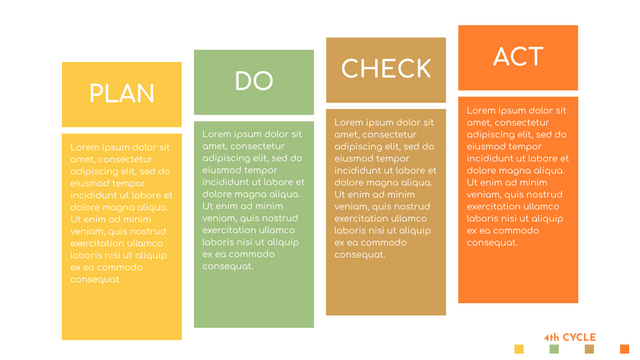

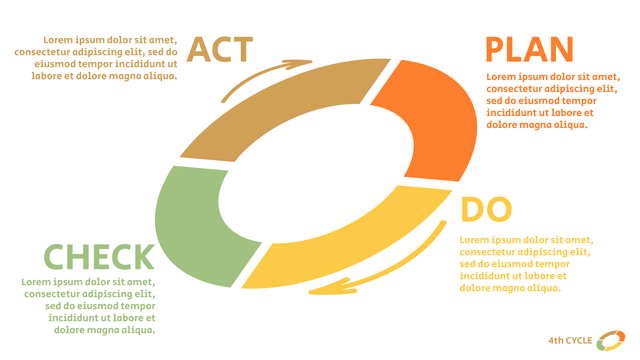

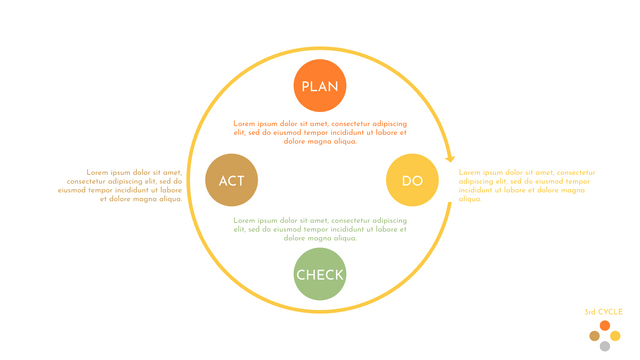

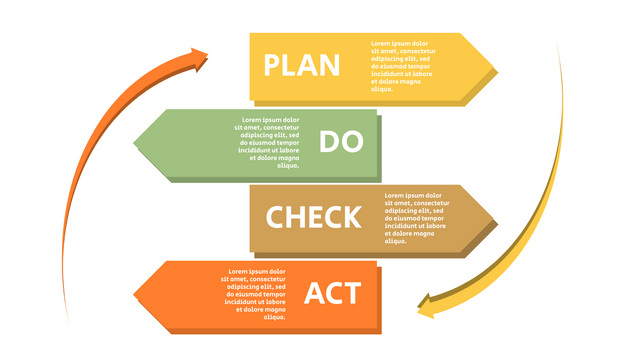

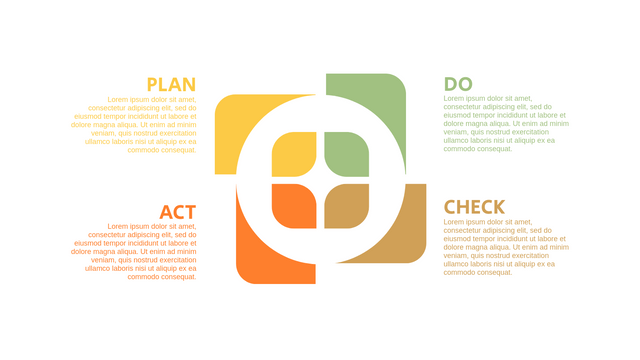

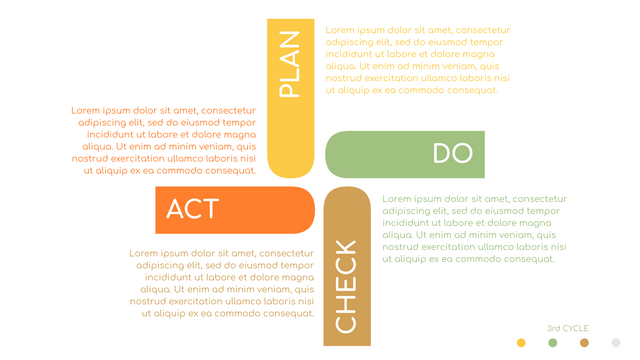

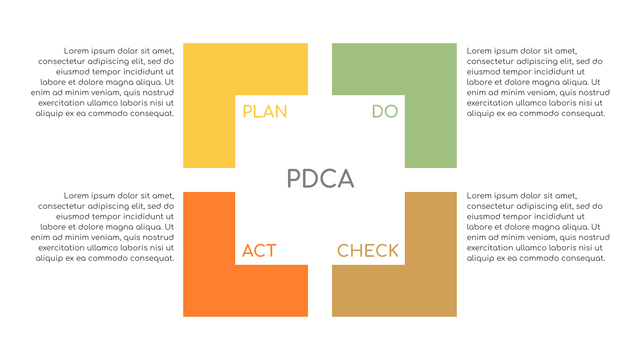

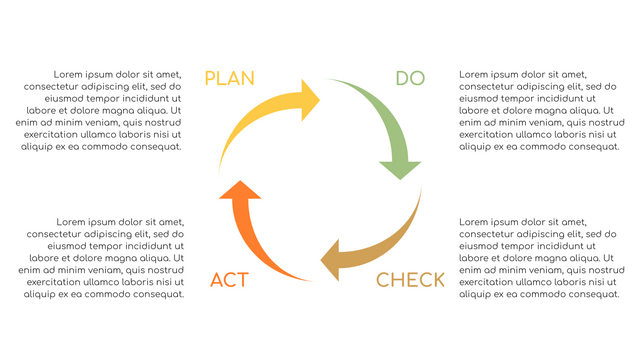

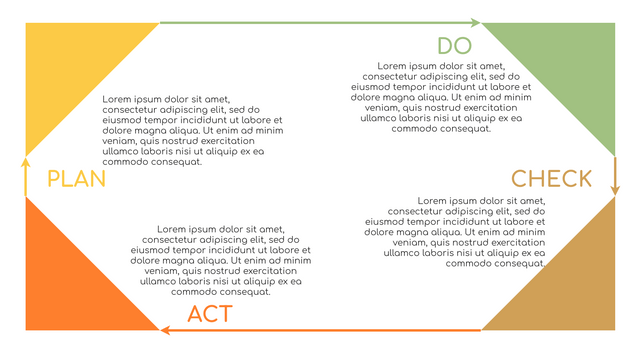

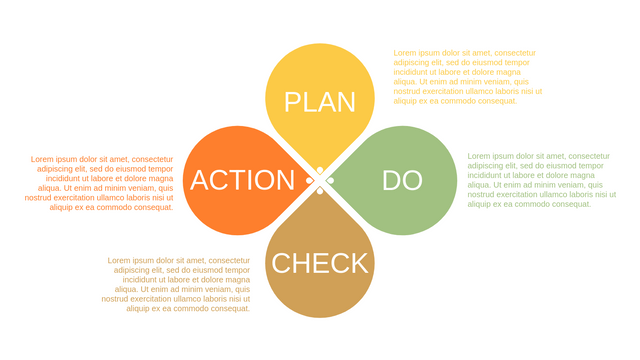

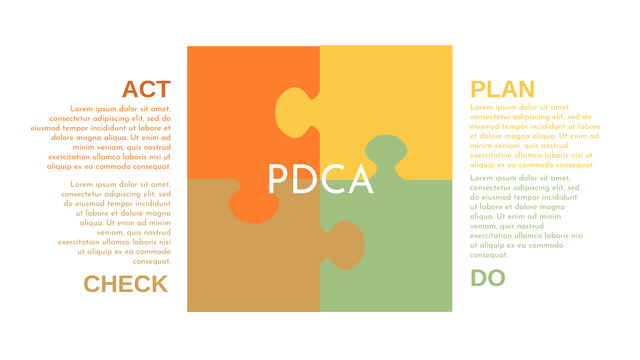

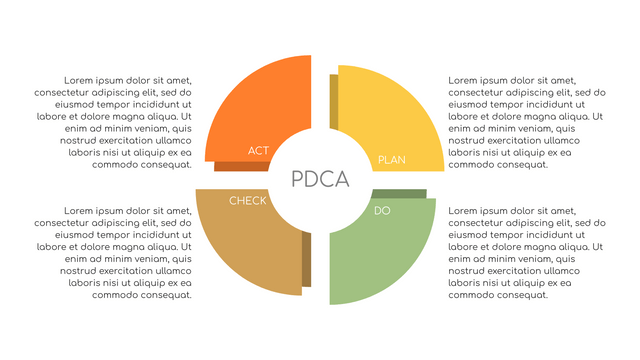

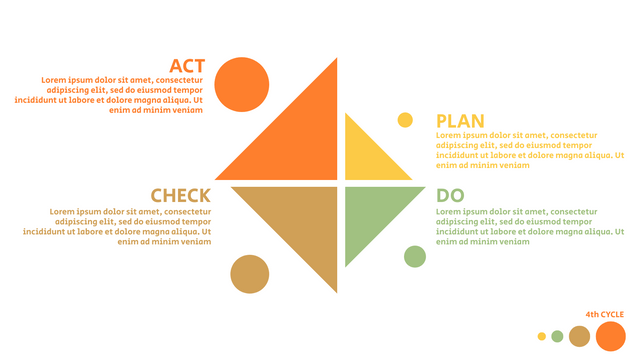

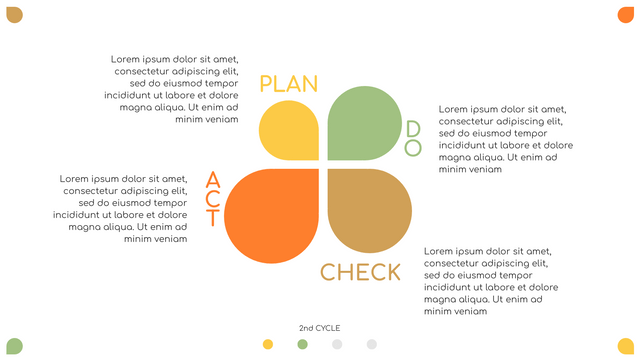

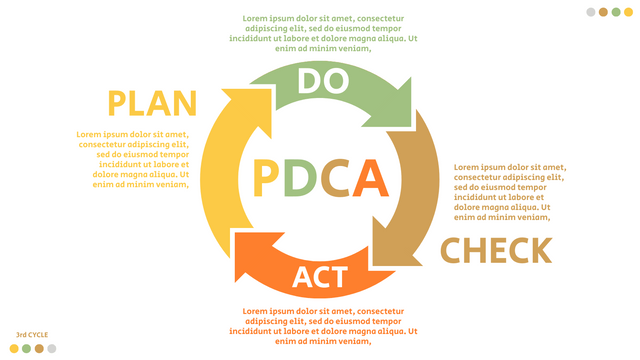

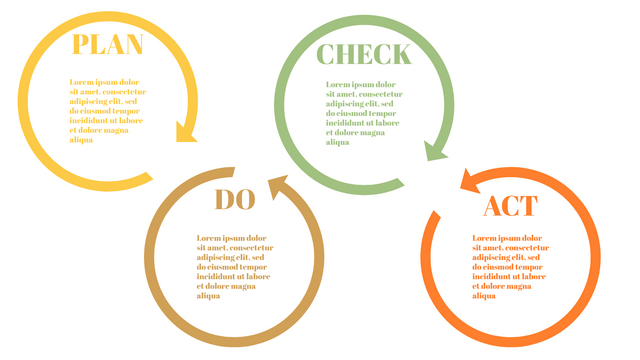

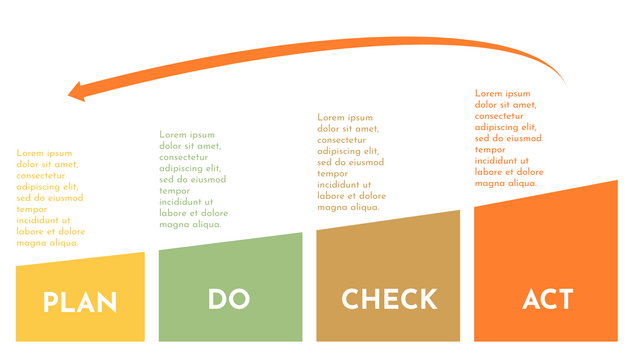

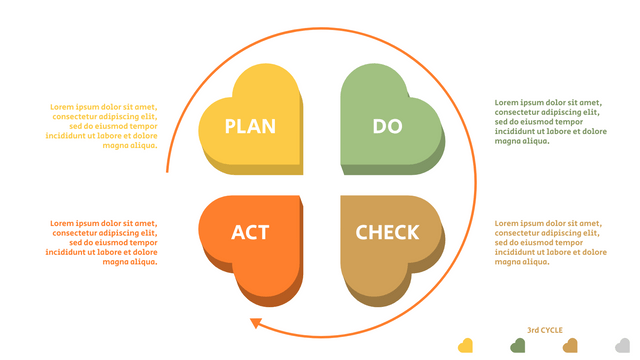

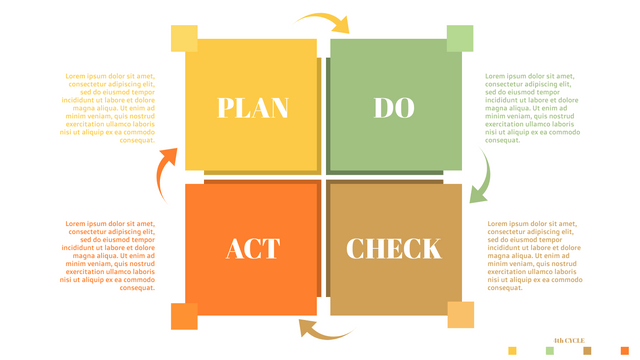

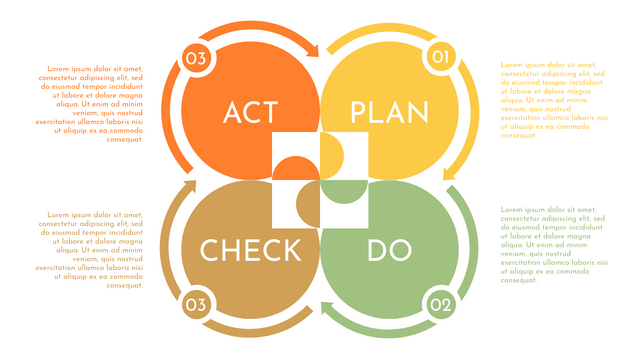

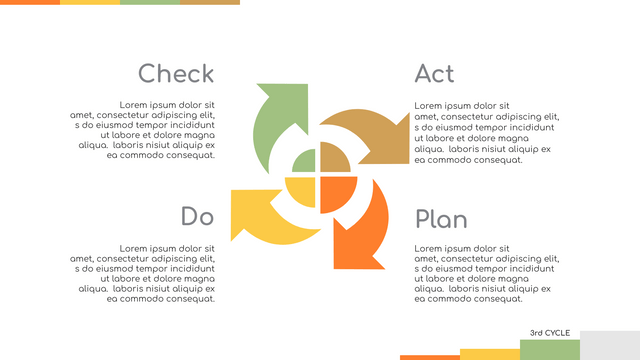

The Deming Cycle is a four-part management approach that advocates continuous improvement. This and other similar continuous improvement models have been integrated into business and enterprise software. The defogging cycle includes:

Plan: Choose a process and set goals

Do: Execute the plan and start collecting the resulting data

Check: Analyze the results statistically

Act: Decide what changes you want to make to improve the process for the next cycle