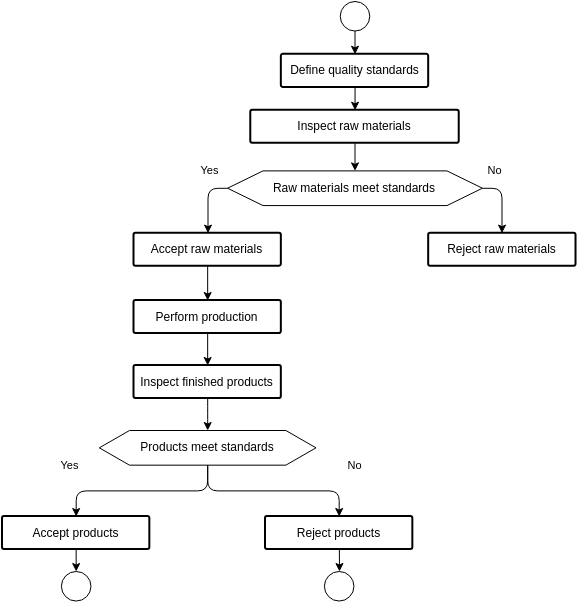

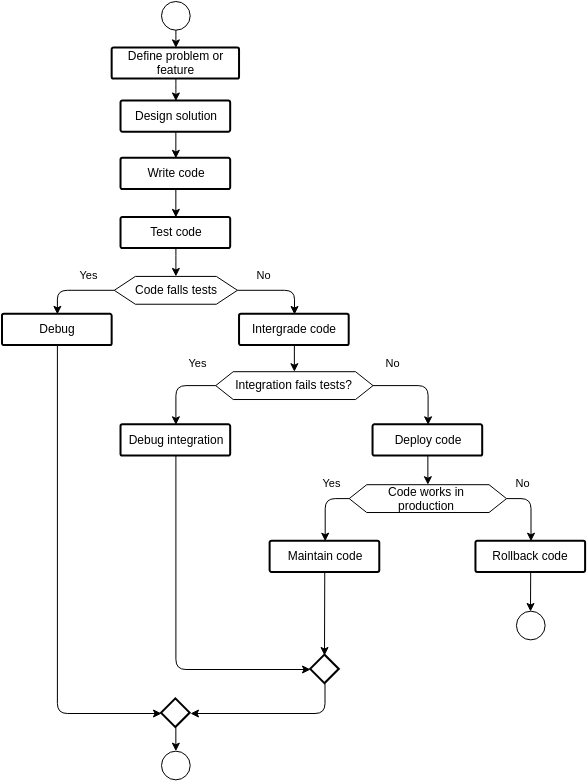

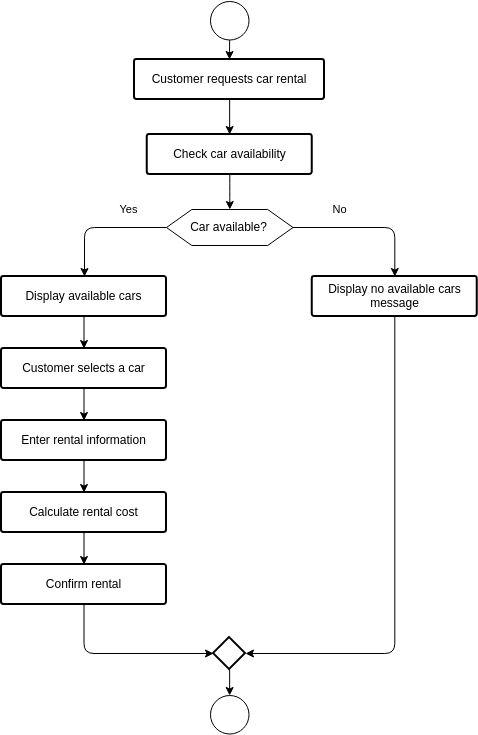

Process of Quality Control

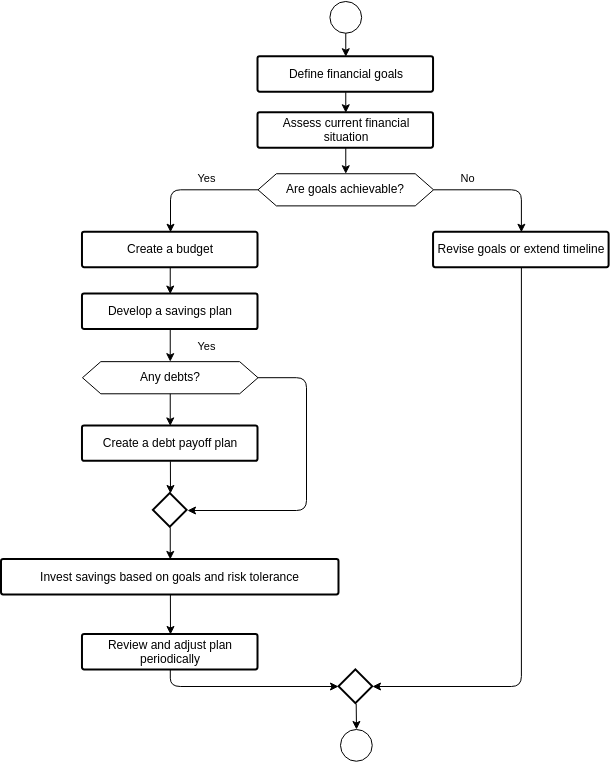

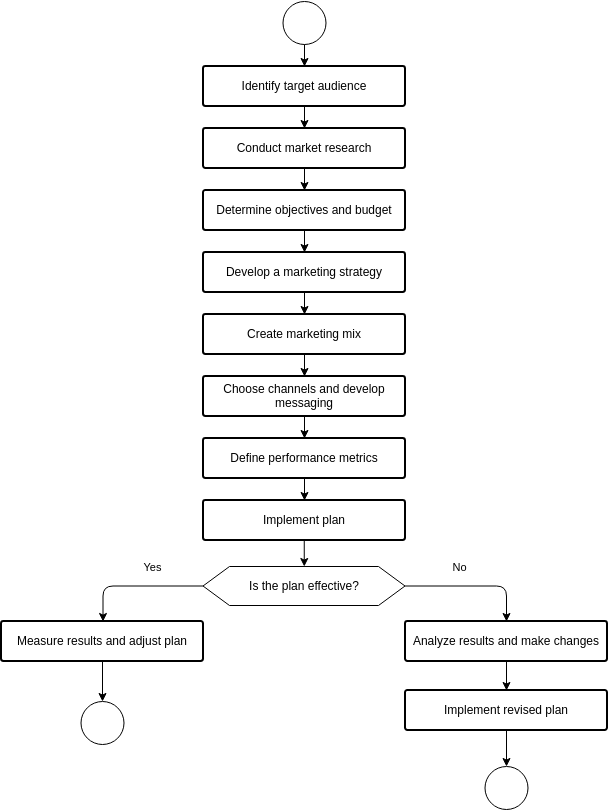

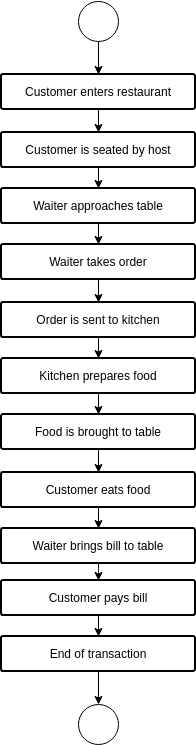

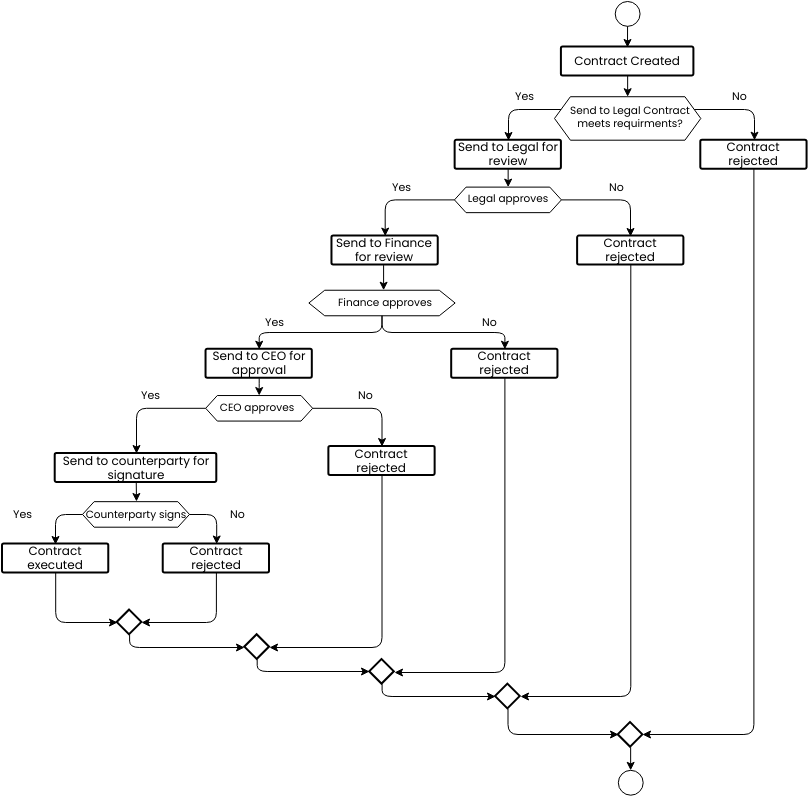

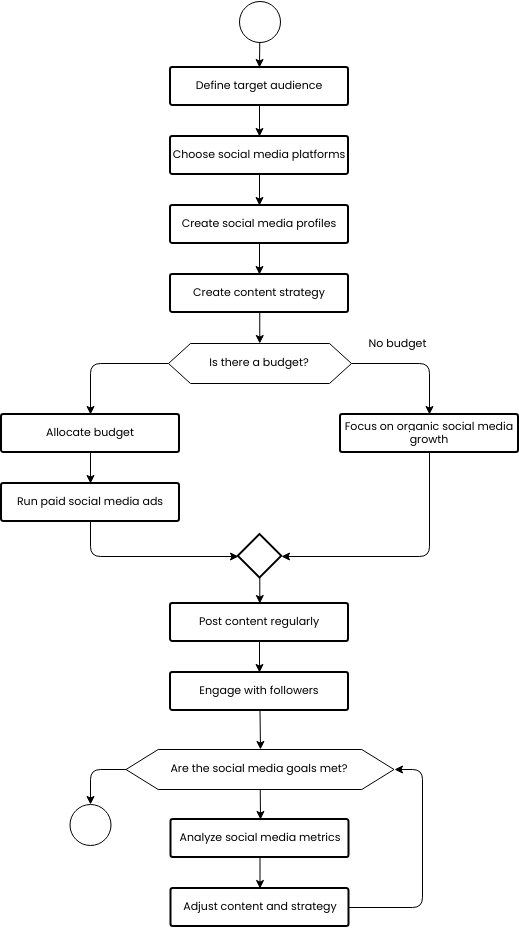

The Process of Quality Control flowchart outlines the steps involved in ensuring that a product meets established quality standards. The process begins with defining quality standards that will guide the inspection and acceptance of raw materials and finished products.

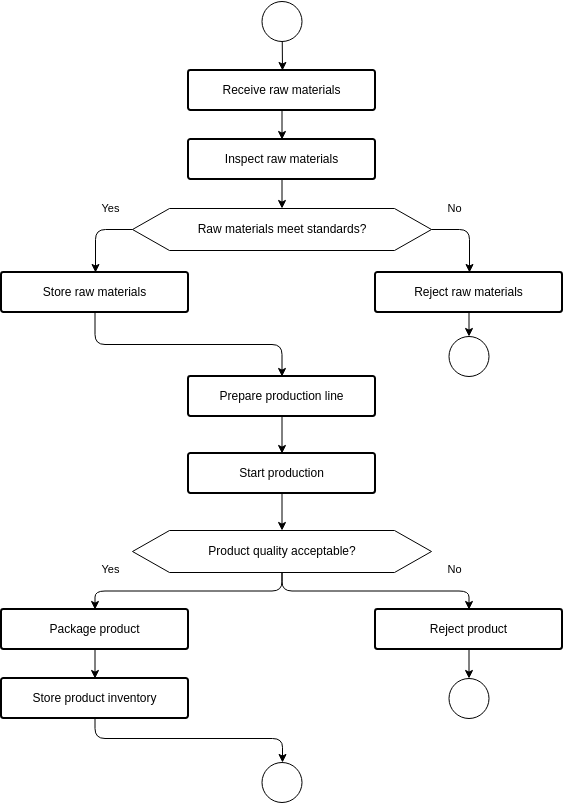

Once the quality standards are established, the next step is to inspect the raw materials that will be used in production. Raw materials that meet the established quality standards are accepted for use in production, while those that do not meet the standards are rejected.

After the raw materials are accepted, production can begin. Throughout the production process, quality control measures are in place to ensure that the product is being produced to the established quality standards.

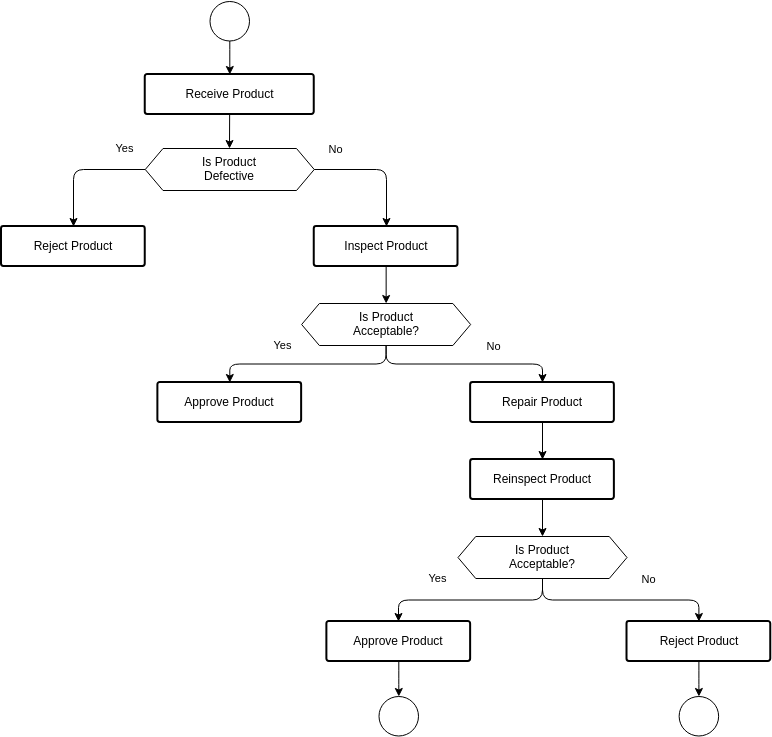

Once production is complete, the finished products are inspected to ensure that they meet the established quality standards. Products that meet the standards are accepted for distribution, while those that do not meet the standards are rejected.

Overall, the Process of Quality Control flowchart is designed to ensure that products meet established quality standards throughout the production process. By following the steps outlined in the flowchart, businesses can ensure that their products are of high quality and meet the needs and expectations of their customers. Effective quality control measures are essential for businesses of all sizes, as they can help to build customer trust and loyalty and ultimately lead to greater success and profitability.

Pros of creating a Process of Quality Control flowchart

Helps to ensure consistency: The flowchart provides a clear and consistent process for ensuring that products meet established quality standards. By following the steps outlined in the flowchart, businesses can ensure that their products are of high quality and meet the needs and expectations of their customers.

Facilitates communication and collaboration: The flowchart can be used to facilitate communication and collaboration between different teams and departments involved in the quality control process. By providing a visual representation of the process, the flowchart can help to ensure that everyone is on the same page and working towards a common goal.

Identifies potential issues: The flowchart can help to identify potential issues or bottlenecks in the quality control process. By anticipating these issues, businesses can take steps to address them proactively and improve the overall quality of their products.

Improves efficiency: By providing a clear and consistent process for quality control, the flowchart can help to improve the efficiency of the production process. This can help businesses to reduce waste, increase productivity, and ultimately improve profitability.

Builds customer trust and loyalty: Effective quality control measures can help to build customer trust and loyalty by ensuring that products meet or exceed their expectations. This can lead to repeat business and positive word-of-mouth recommendations, ultimately contributing to the overall success of the business.

Are you looking for any templates for creating flowchart? Right away, go to Visual Paradigm Online to browse the available templates.