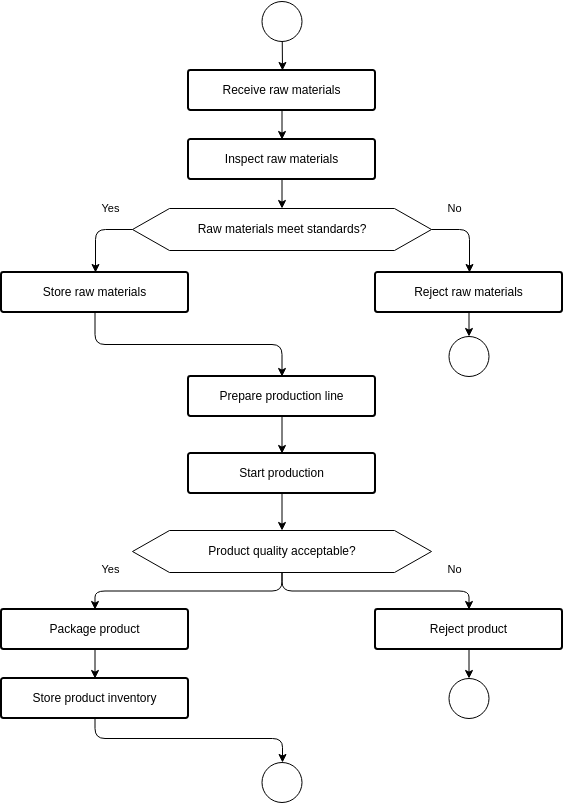

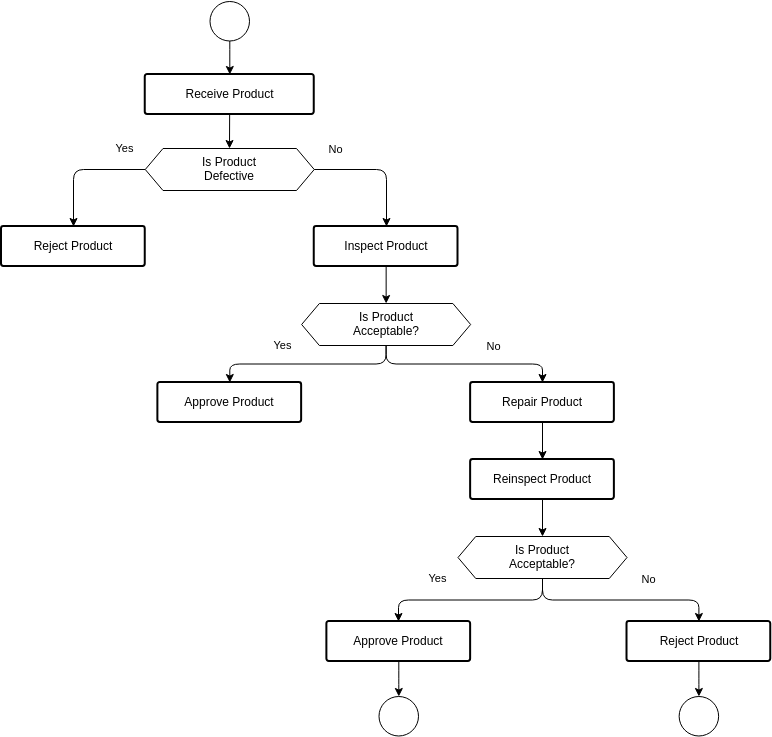

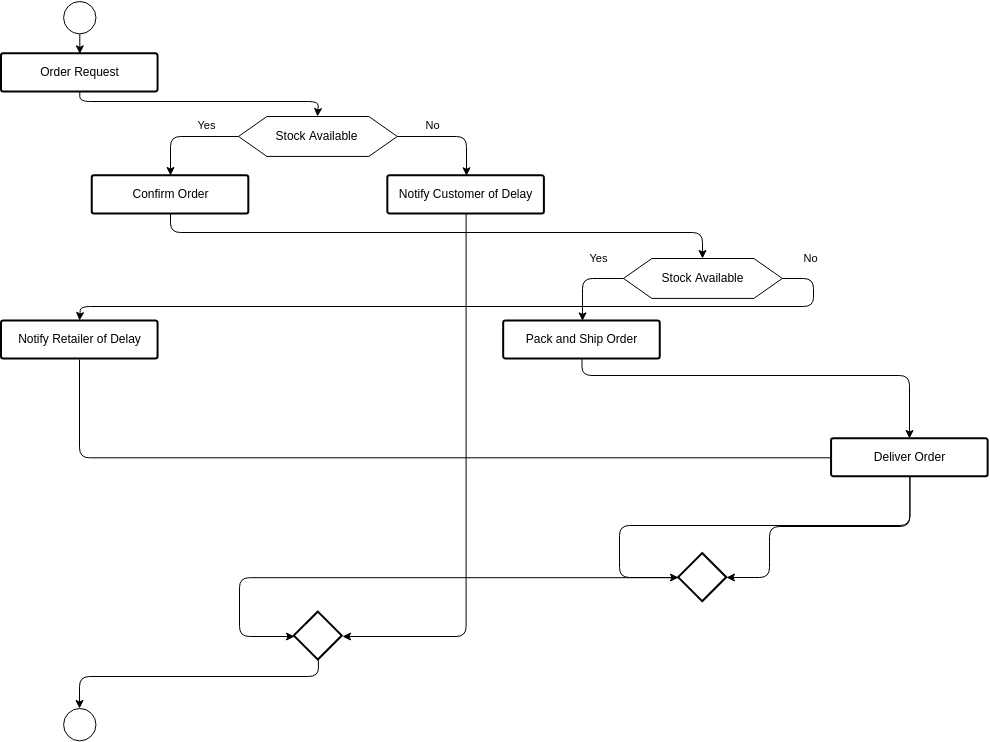

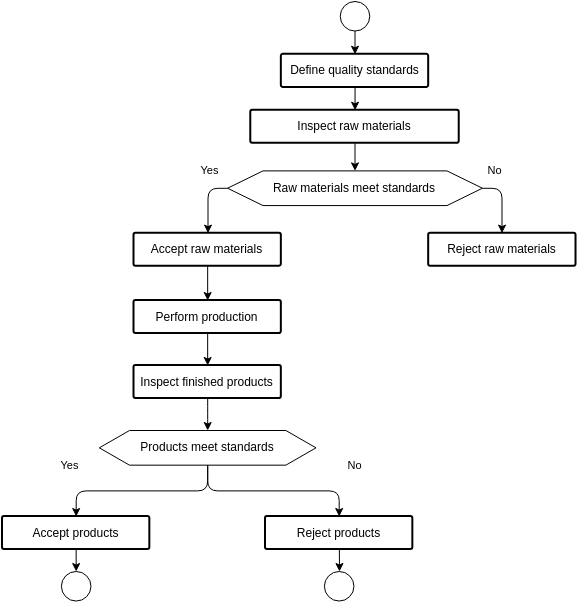

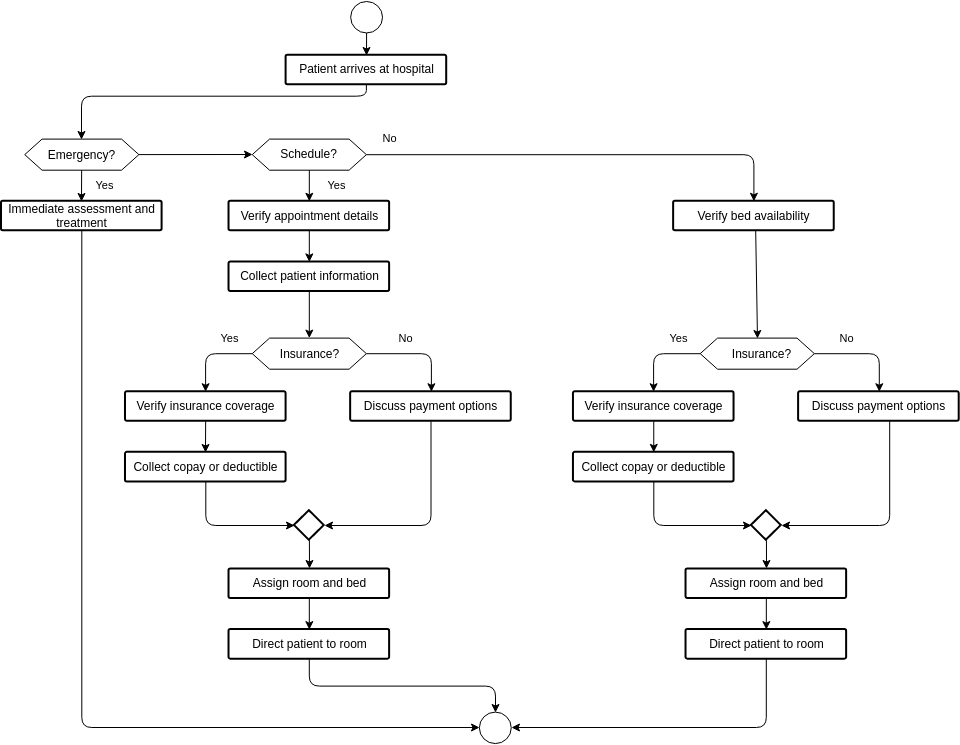

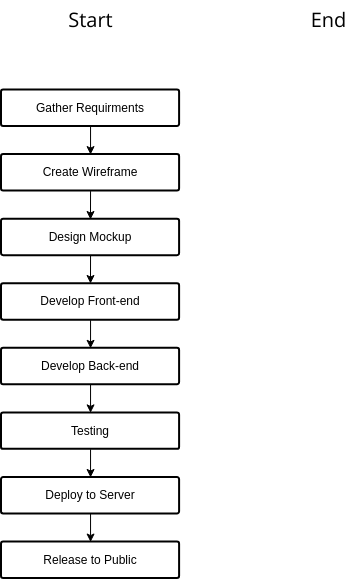

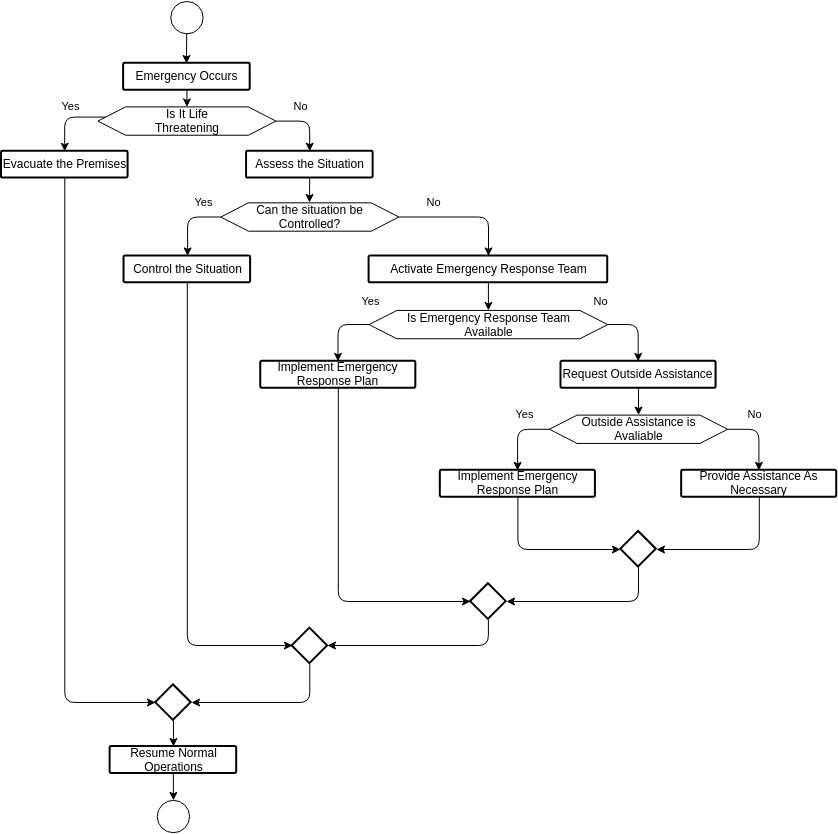

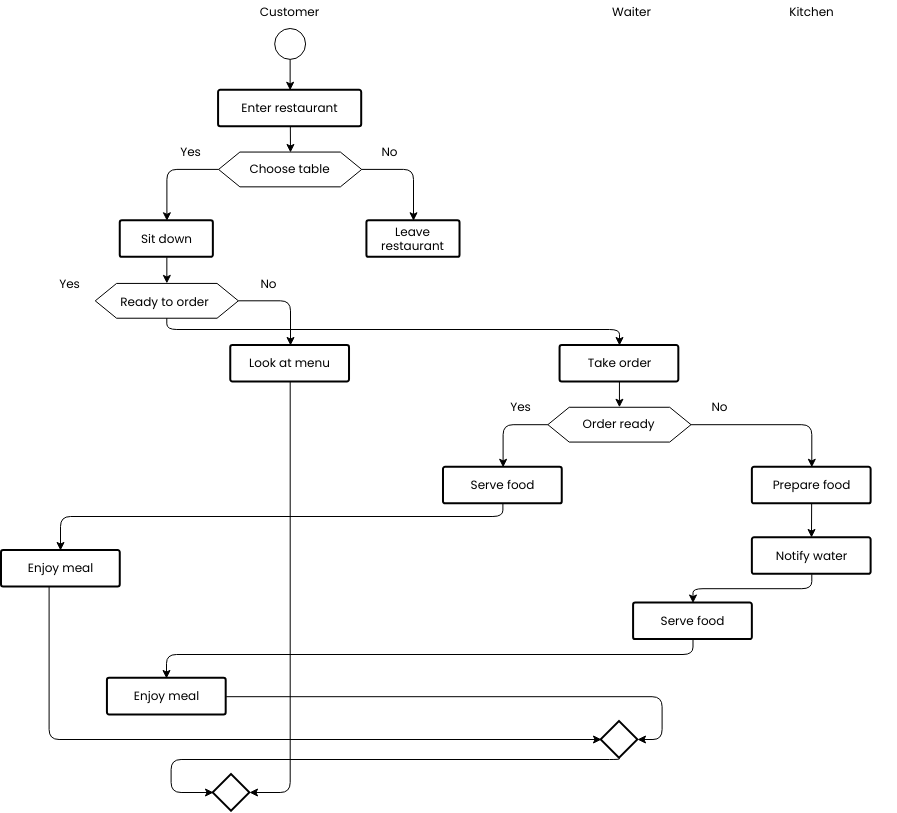

Flowchart for a manufacturing process

This flow chart outlines the process of manufacturing a product from raw materials to finished goods. The process begins with the receipt of raw materials, which are then inspected for quality and any defects. Once the materials have been inspected, they are stored in a designated location until they are needed for production.

Next, the production line is prepared for manufacturing, which includes setting up the necessary equipment and ensuring that all safety procedures are in place. Once the production line is ready, the manufacturing process begins.

During production, the raw materials are transformed into the finished product through a series of steps, which may include mixing, heating, cooling, or other processes depending on the product being manufactured. Throughout the production process, quality control measures are implemented to ensure that the finished product meets the required standards.

Once the product has been manufactured, it is packaged for shipment and storage. Packaging may include labeling, boxing, or other methods of packaging depending on the requirements of the product. The finished product is then stored in inventory until it is ready to be shipped to customers or retailers.

Overall, this flow chart provides a clear and structured approach to manufacturing a product from raw materials to finished goods. By following the steps outlined in the flow chart, manufacturers can ensure that their products are of high quality and meet the necessary standards. Additionally, the flow chart emphasizes the importance of quality control and safety procedures throughout the manufacturing process, which is crucial for producing safe and reliable products.

Benefits of using this flowchart for manufacturing process

The flowchart for the manufacturing process offers several benefits. Firstly, it provides a well-structured and systematic approach, reducing the likelihood of errors and increasing efficiency. By following the flowchart, manufacturers can ensure that no crucial steps are missed, such as inspecting raw materials and implementing quality control measures. Additionally, the flowchart highlights the importance of safety procedures, helping to protect workers and guarantee the safety of the final product. The flowchart also allows manufacturers to identify areas where the manufacturing process can be improved, such as optimizing the production line or enhancing quality control measures. Overall, the flowchart is a valuable tool for manufacturing high-quality products in a safe and efficient manner.

Looking for calendar graphic design templates? Visit Visual Paradigm Online right away to look at some customizable templates that you prefer.