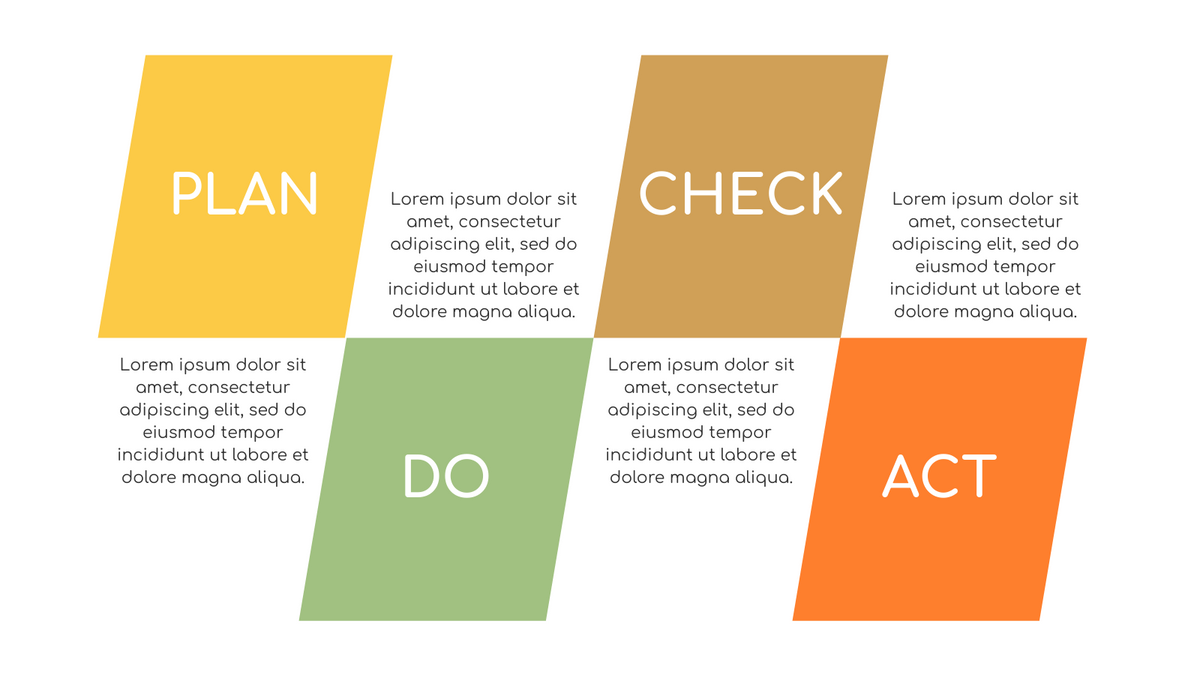

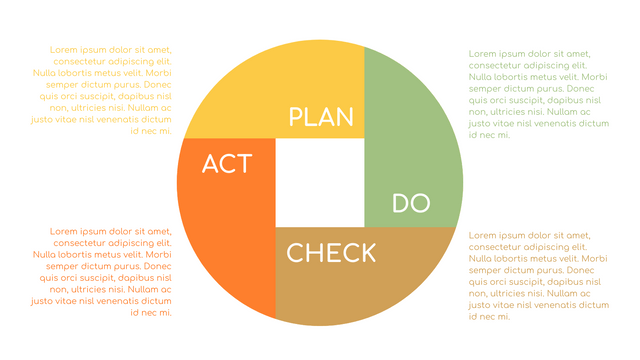

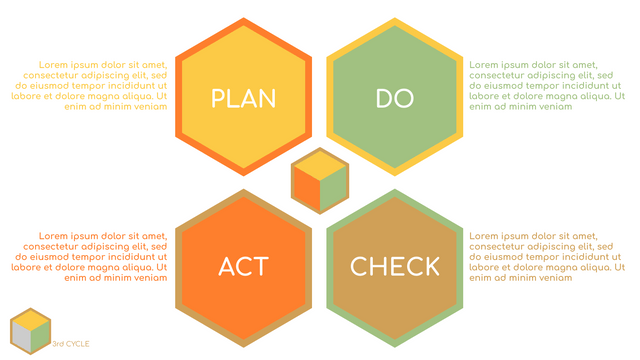

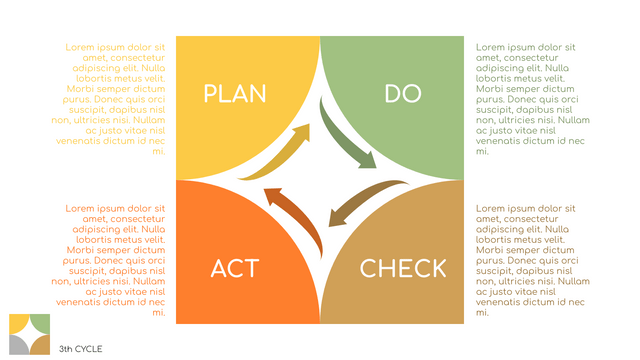

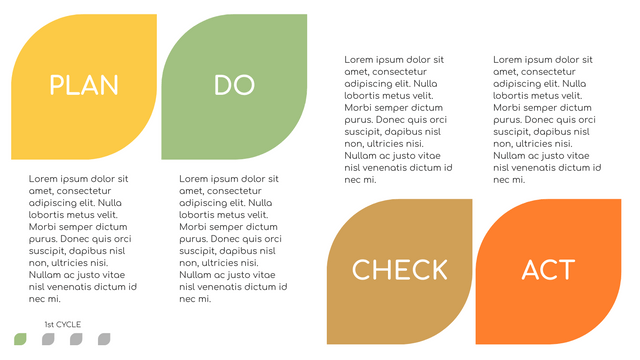

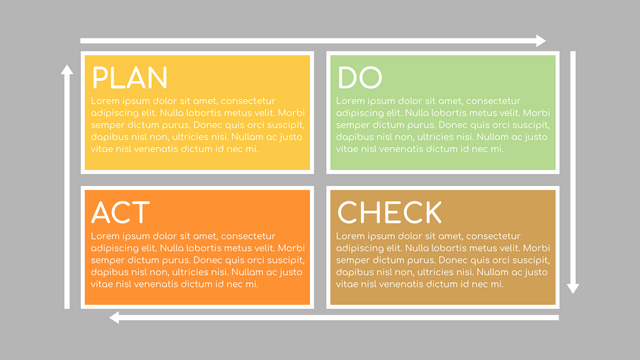

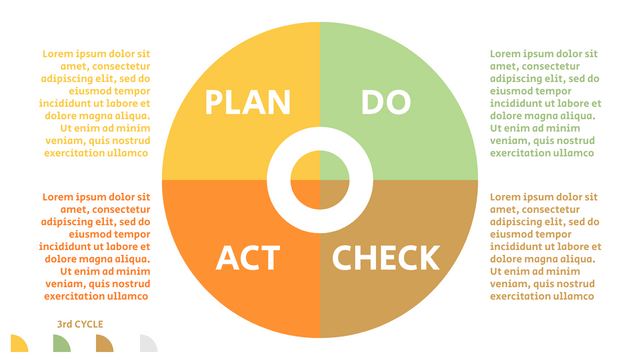

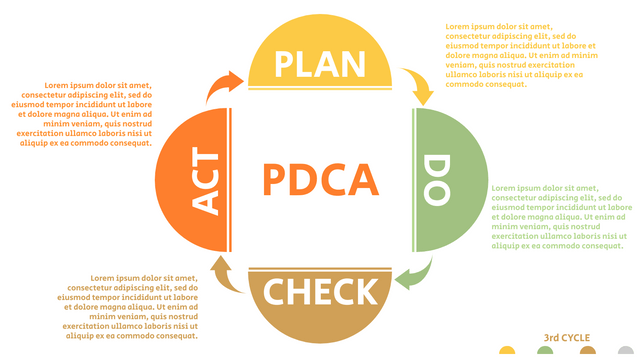

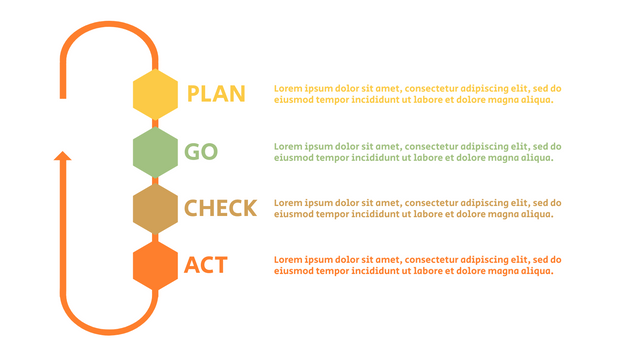

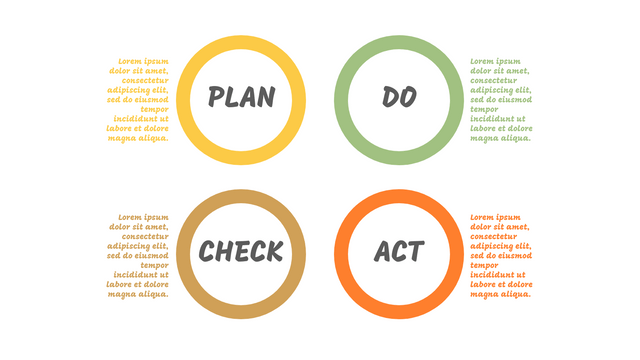

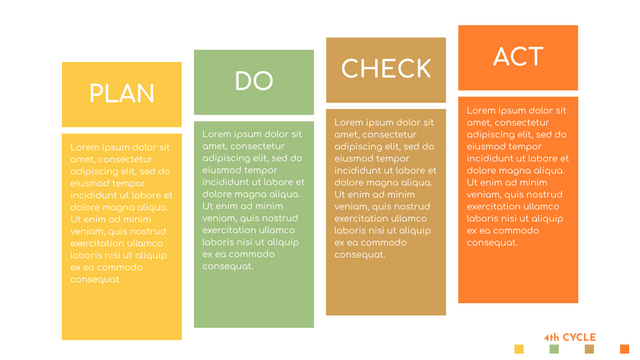

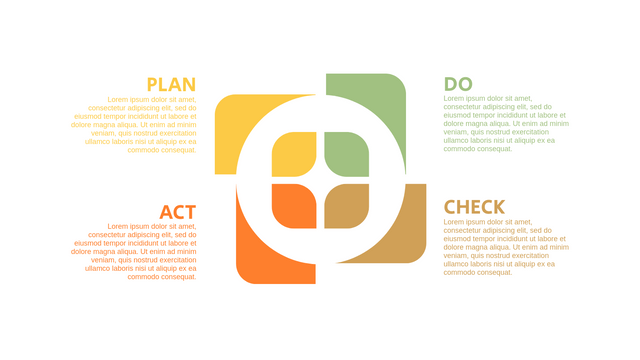

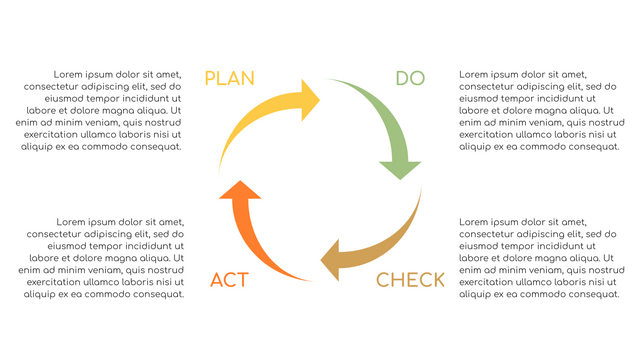

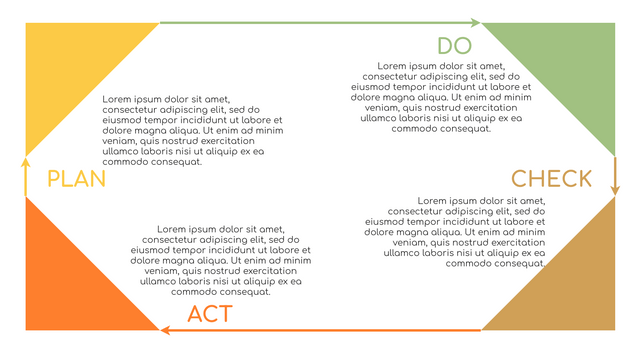

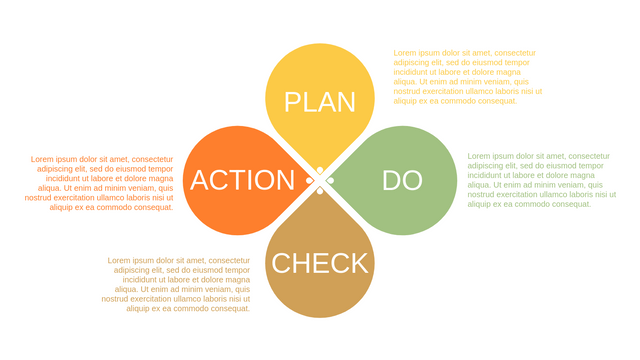

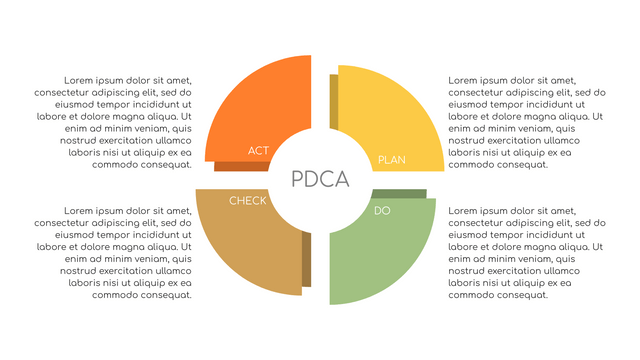

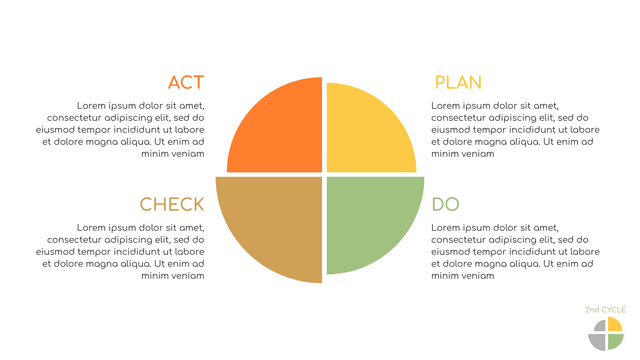

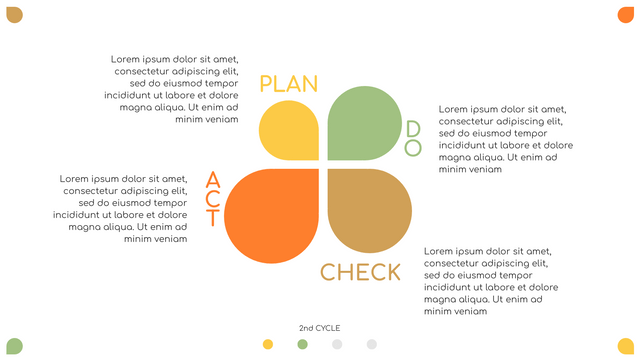

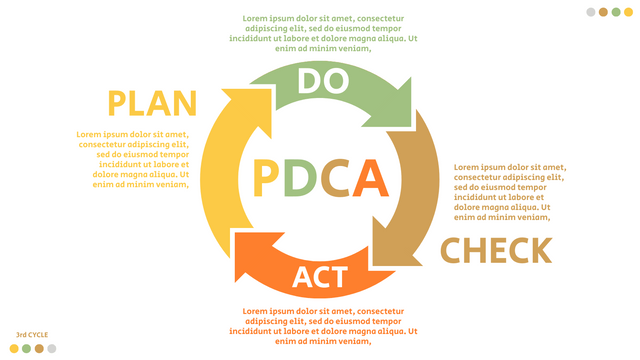

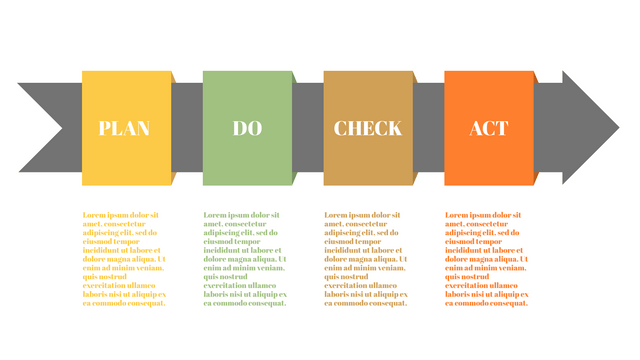

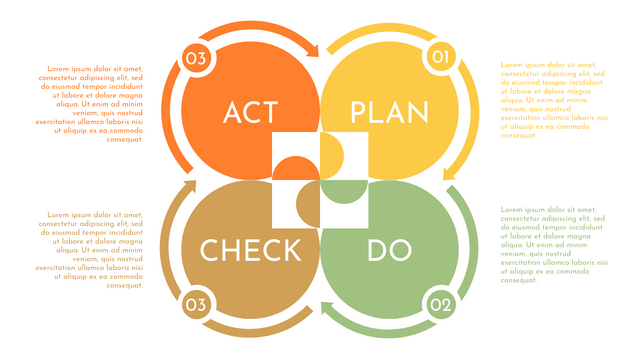

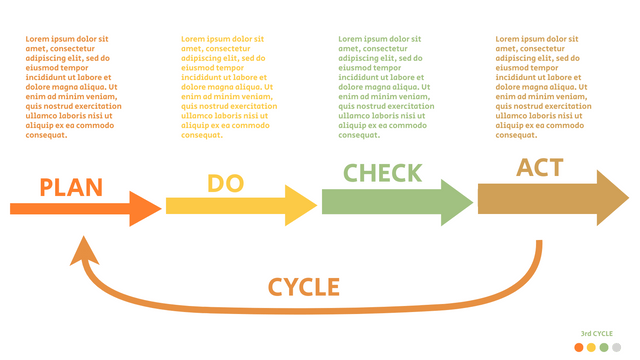

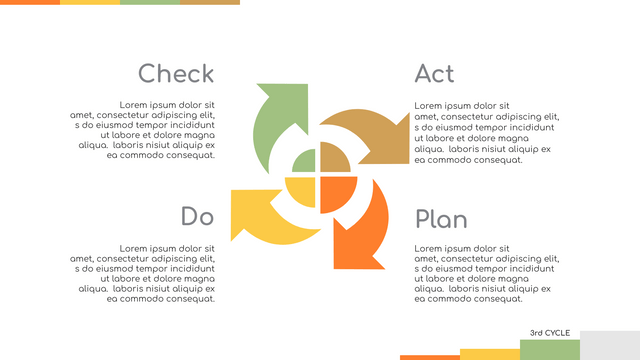

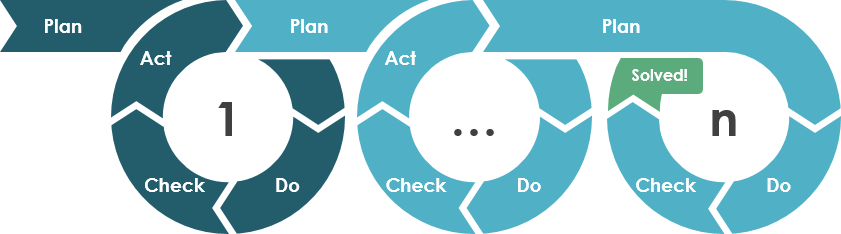

PDCA cycle, also known as Deming ring, is developed by American quality management expert Deming, which is a scientific procedure to be followed by TQM. The meanings of PDCA are as follows:

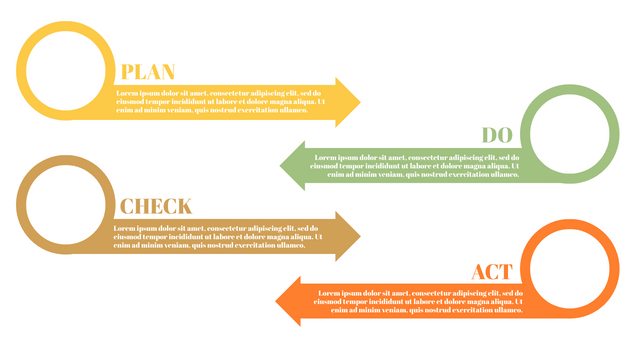

P (plan): determine the policy and objective, determine the activity plan

D (do) implementation: do it on the spot to realize the contents of the plan

C (check): check the effect, compare the actual work result with the expected goal, and check the implementation of the plan

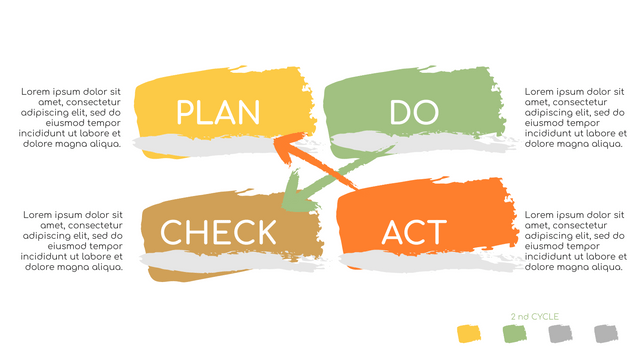

A (action) processing: the results of the summary inspection are processed, and the successful experience is affirmed and appropriately promoted and standardized; the lessons of failure are summarized to avoid recurrence; the unsolved problems are put into the next PDCA cycle.

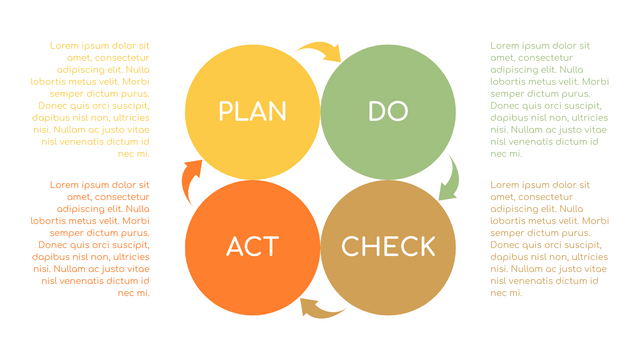

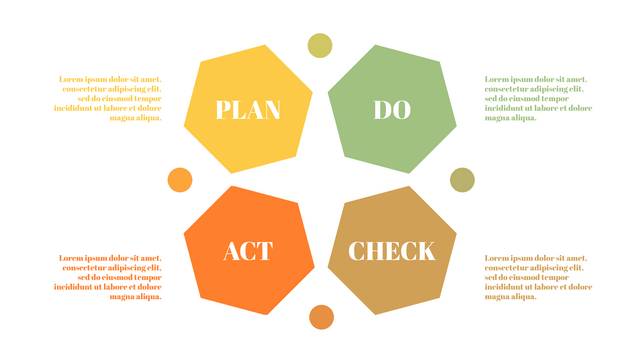

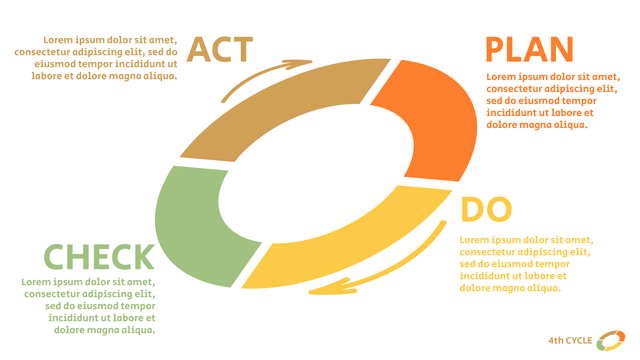

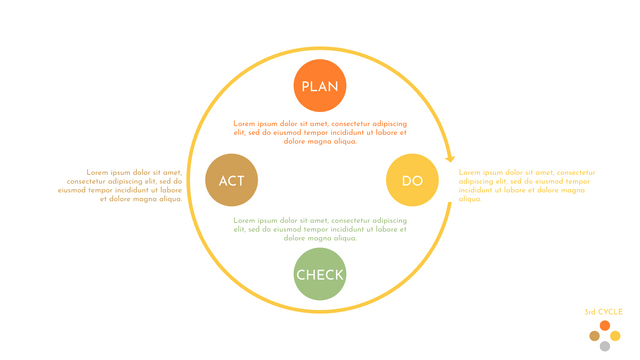

The Parts of PDCA Cycle

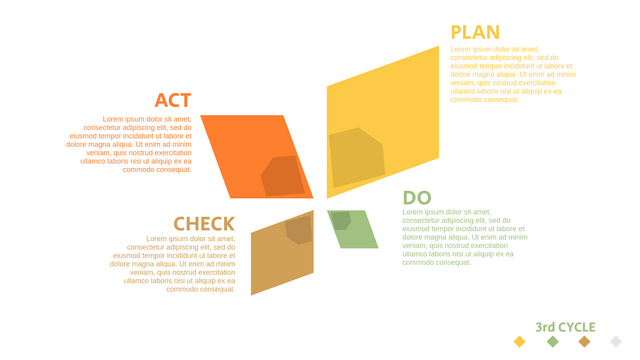

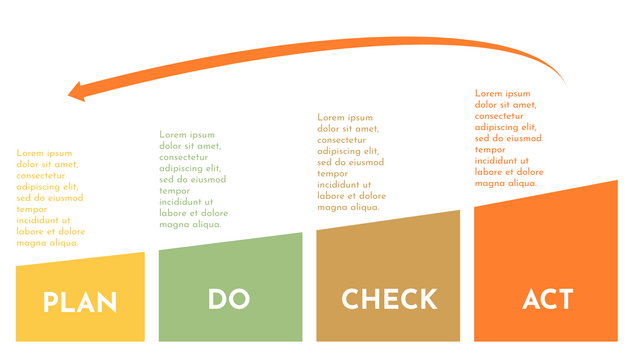

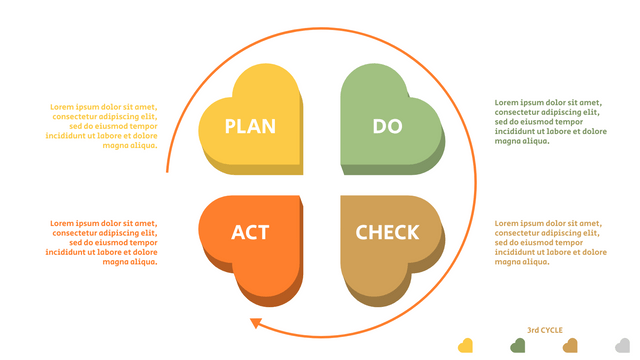

The four parts constitute a complete, unified and continuous PDCA cycle. The above four processes do not end in one run, but go on round and round. When one cycle is over, some problems are solved, and the unsolved problems are entered into the next cycle iteratively.

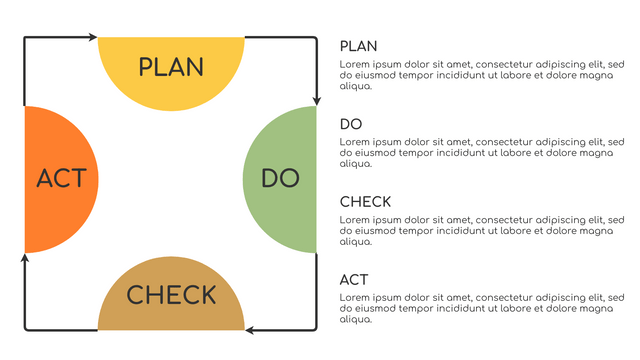

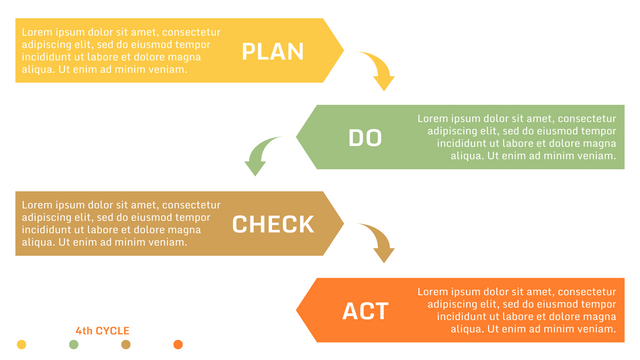

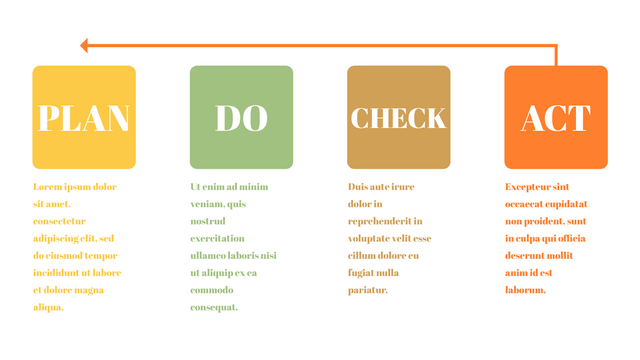

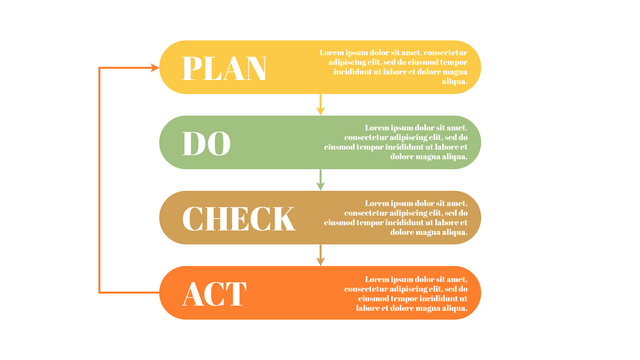

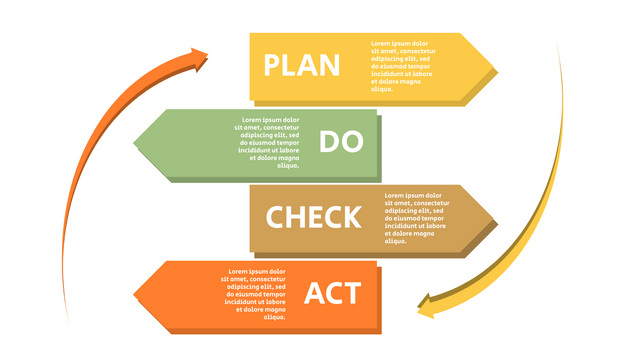

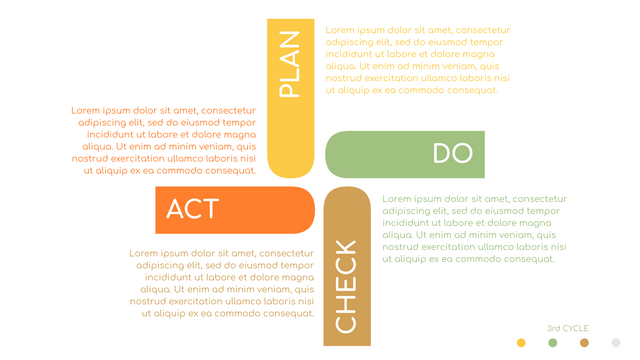

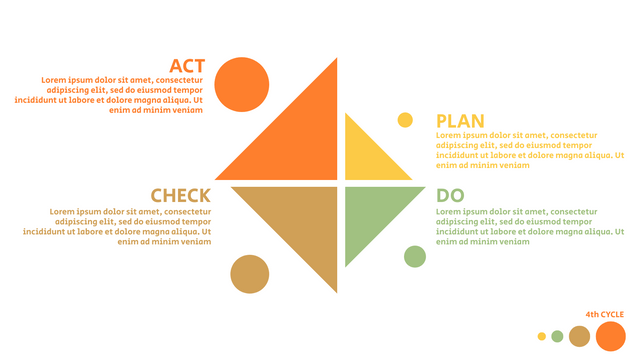

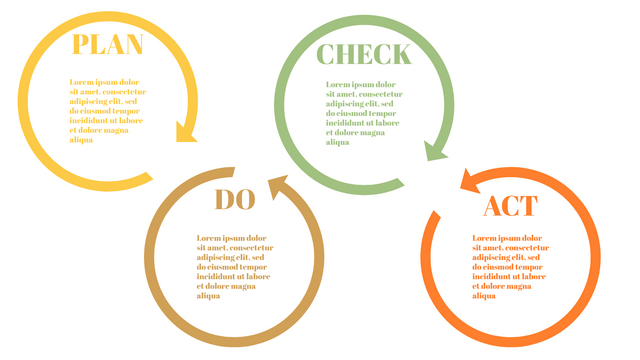

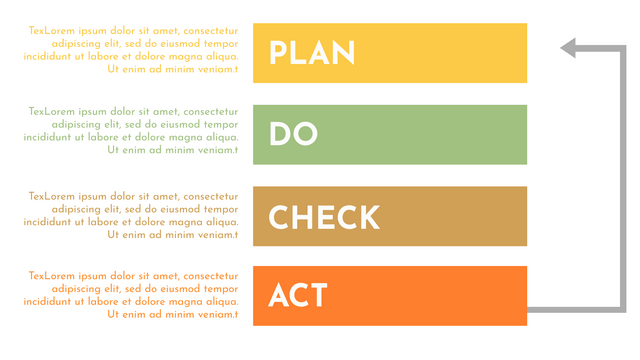

How to implement PDCA

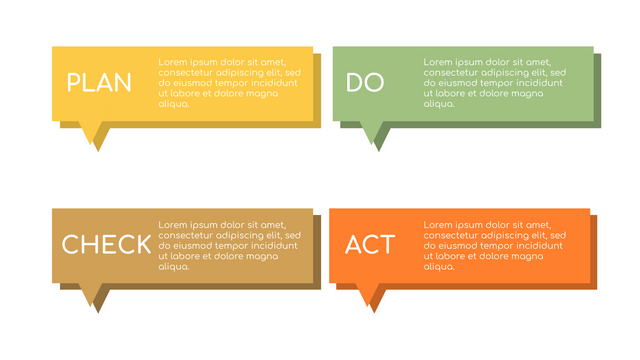

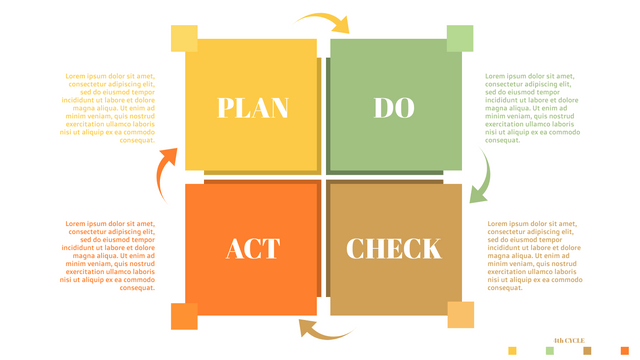

PLAN :

Analyze the current situation and find out the existing problems;

Analyze the cause or influencing factors of the problem;

Find out the main cause of the problem or the main factor affecting;

Develop measures and propose action plans;

DO :

Implement an action plan;

CHECK :

Evaluation results (analysis of data);

ACTION :

Standardization and further promotion;

Re-use the PDCA cycle in the next improvement opportunity;