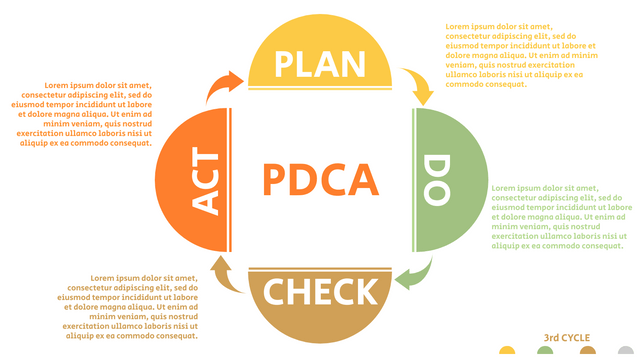

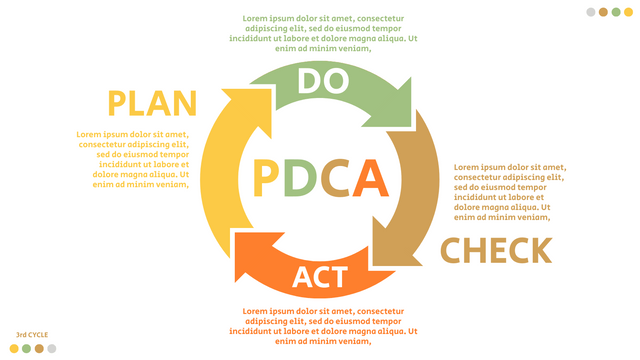

The PDCA cycle, known as the quality cycle, is a common model of management science, first conceived by Walter A. Shewhart in 1930, and later re-discovered and continued to be widely publicized and applied in 1950 by William Edwards Deming, an American quality management expert.

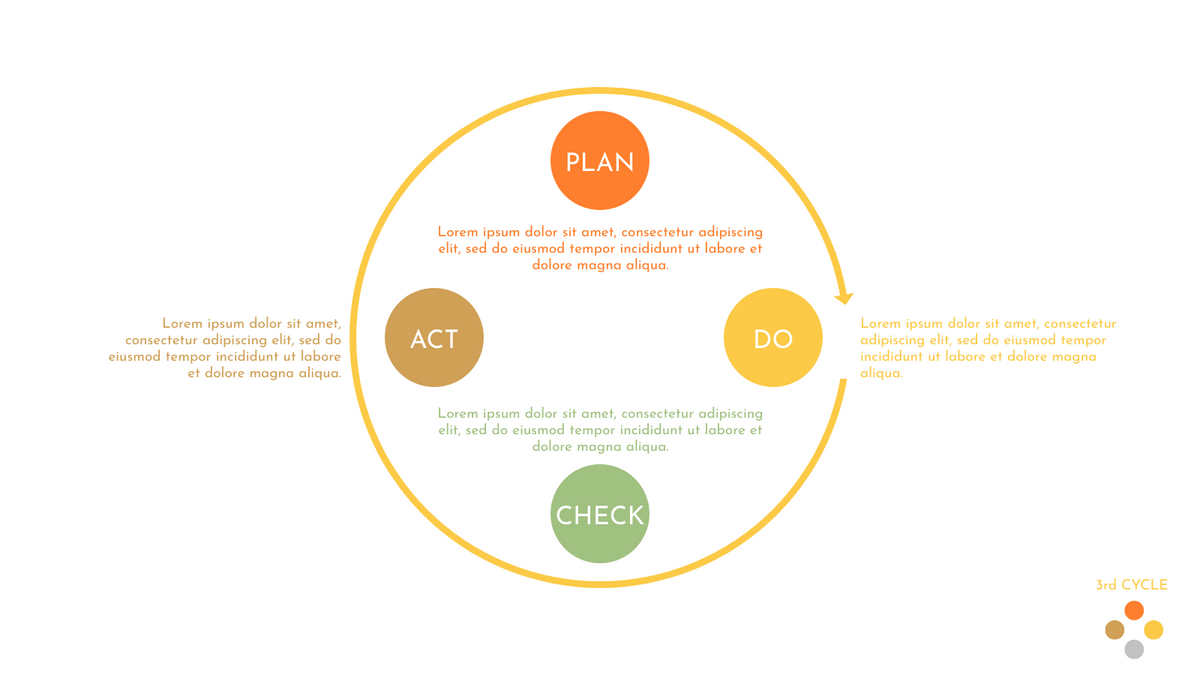

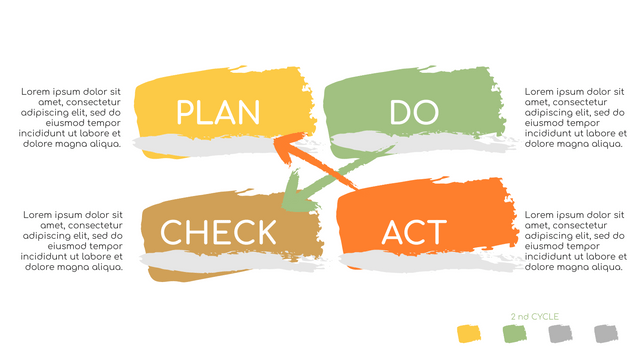

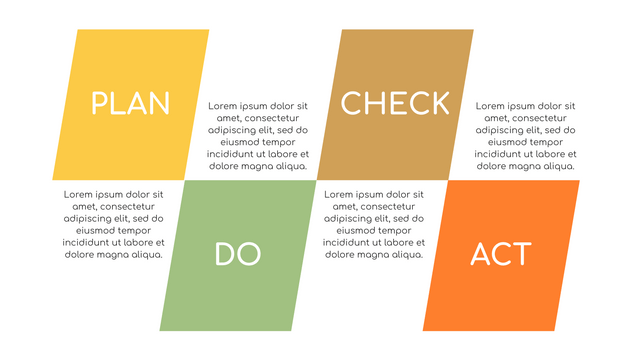

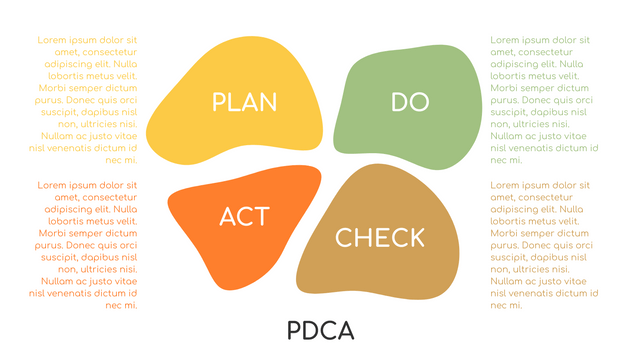

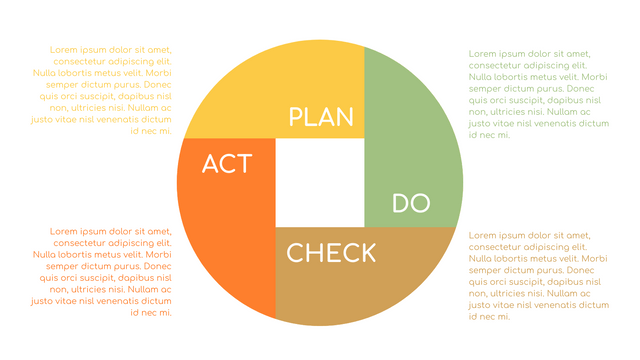

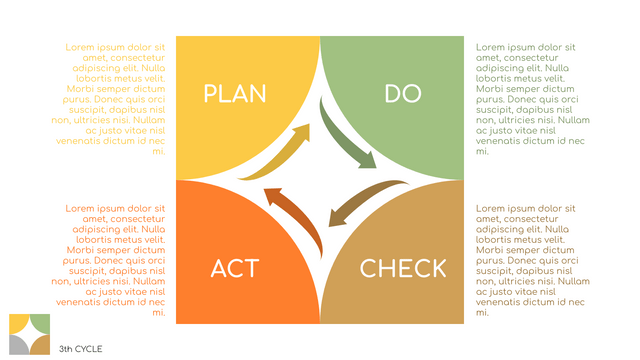

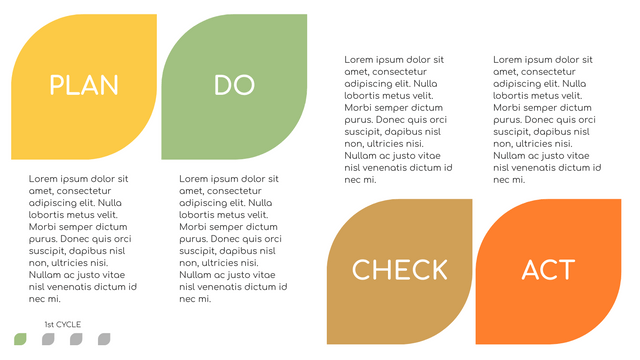

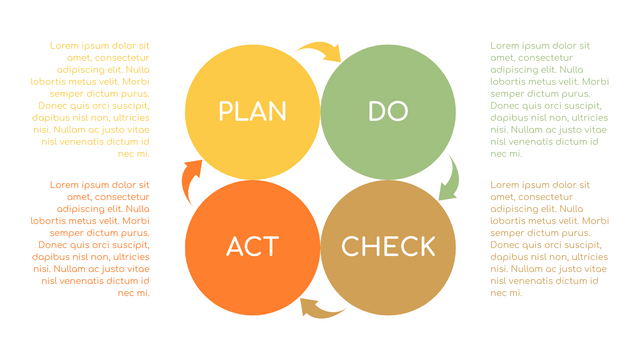

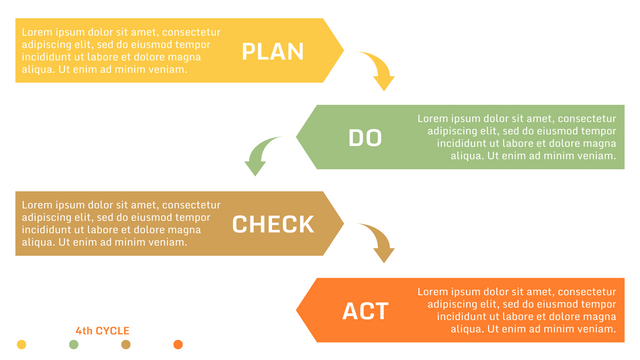

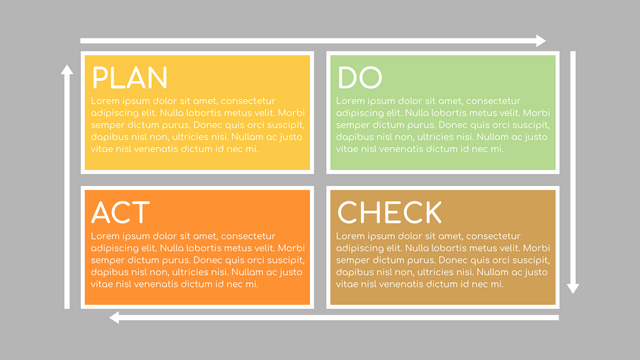

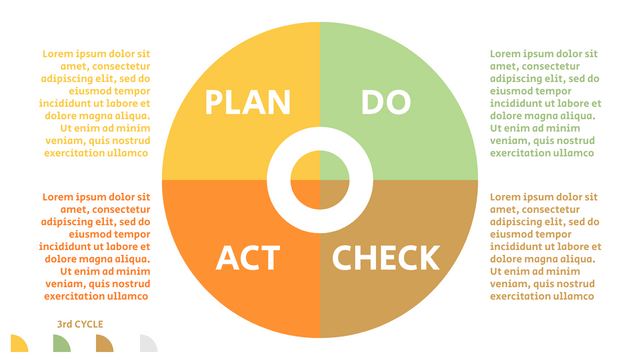

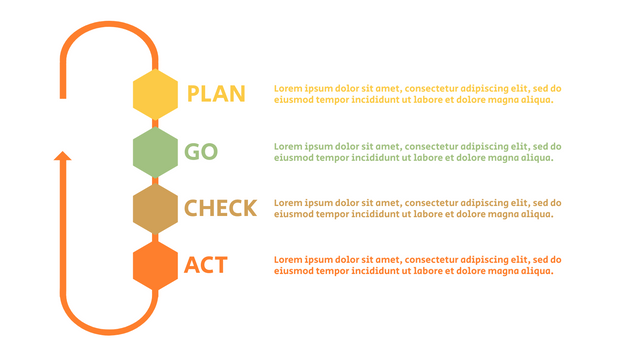

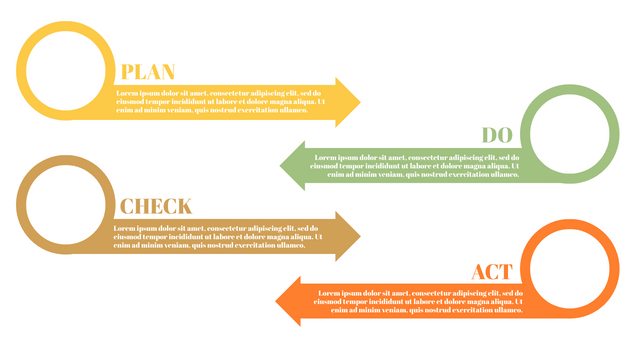

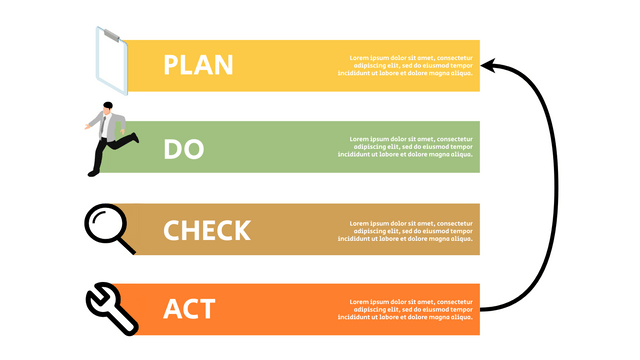

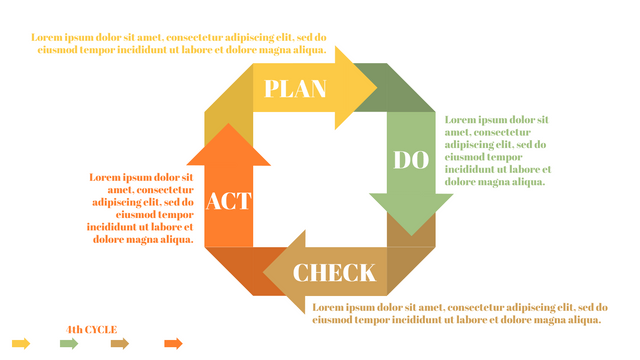

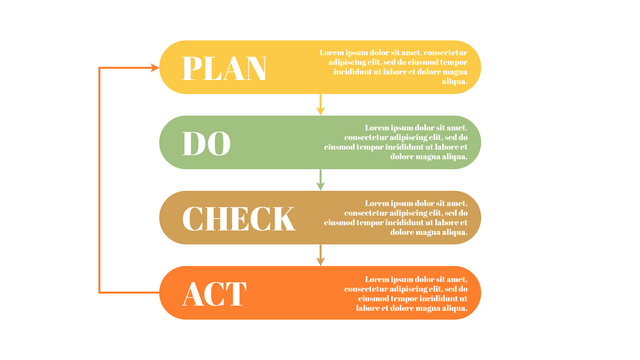

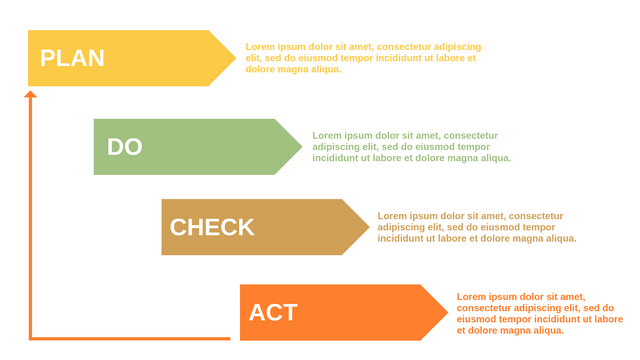

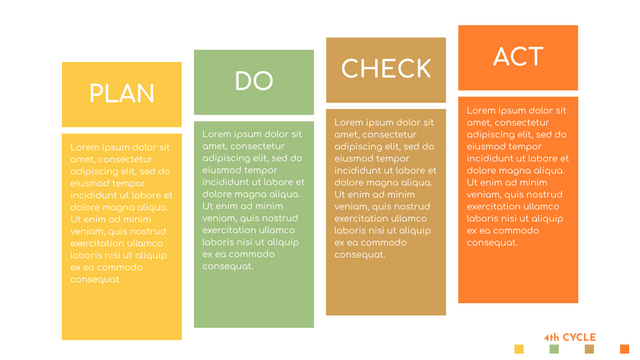

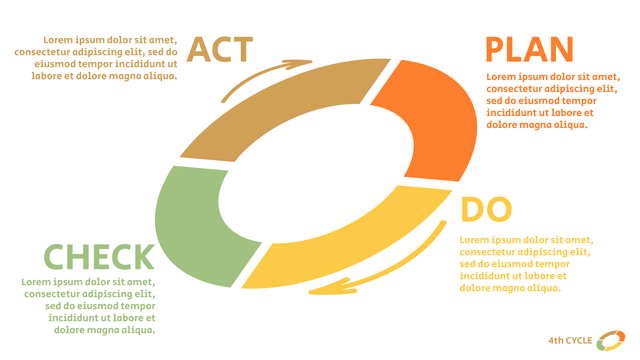

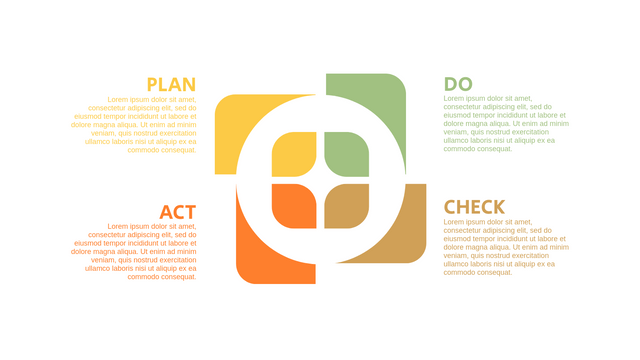

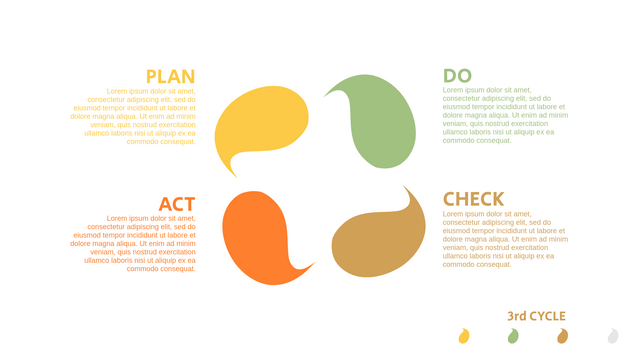

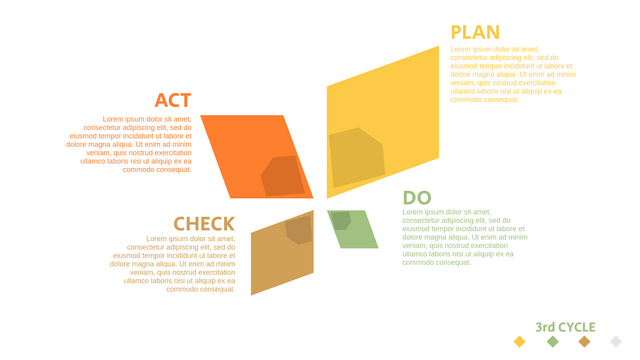

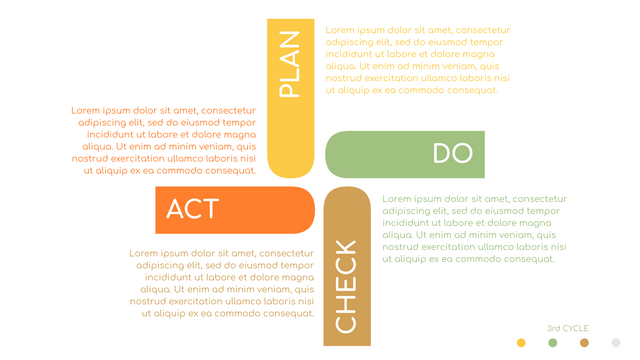

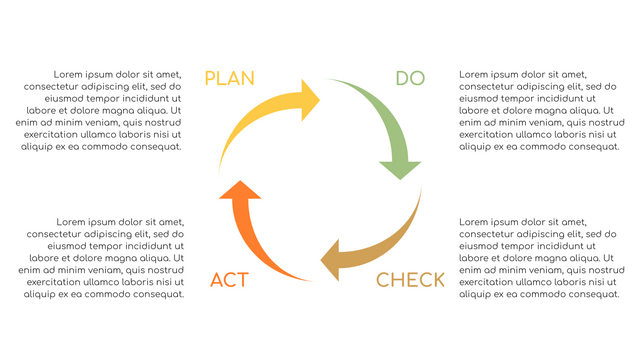

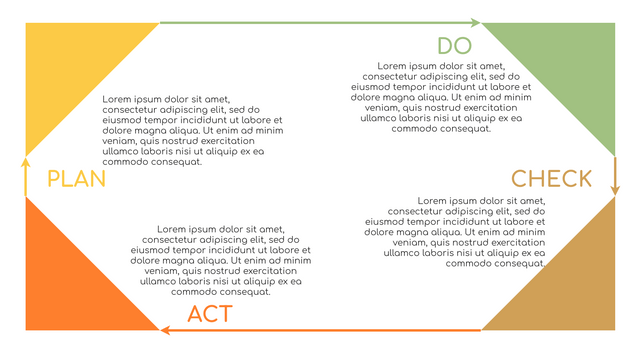

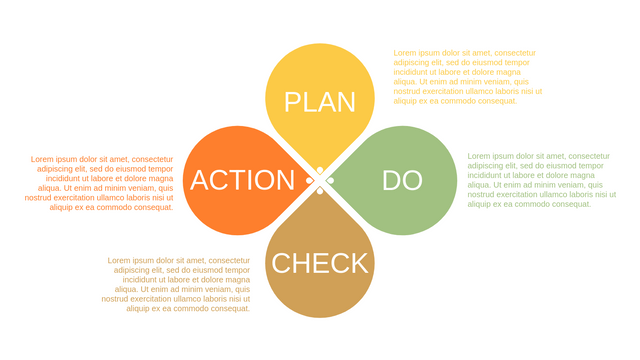

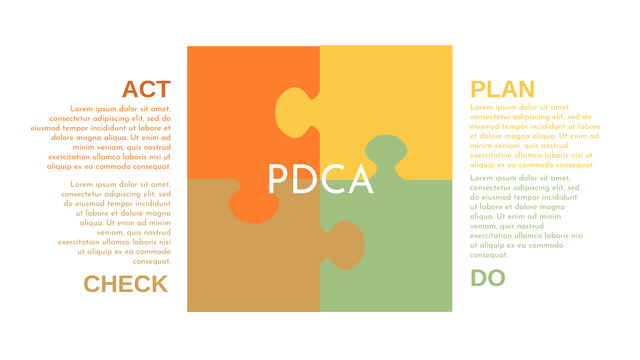

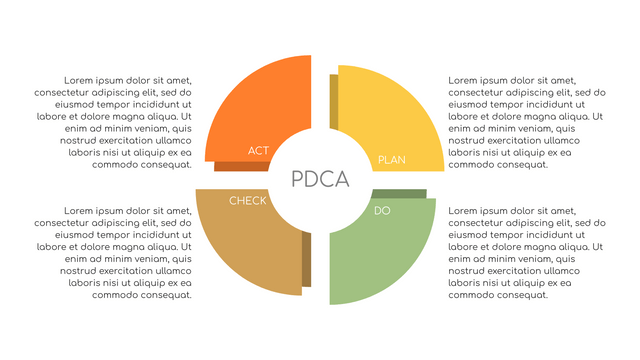

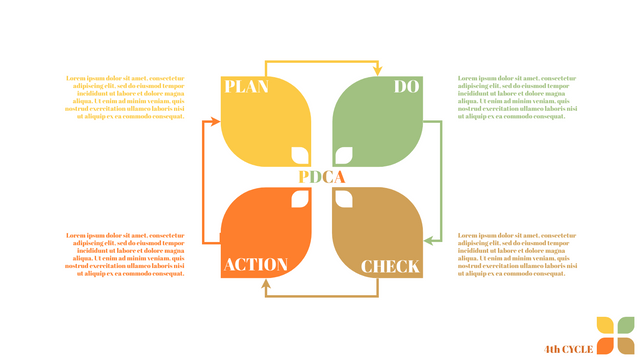

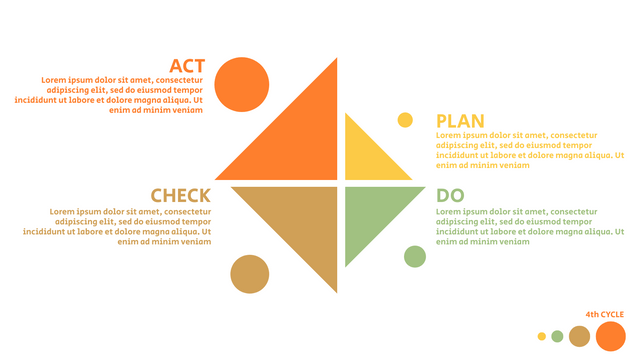

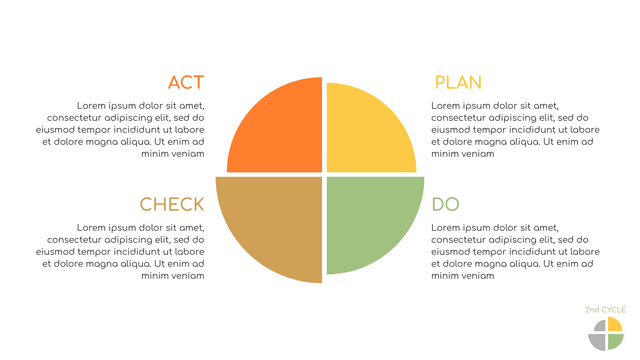

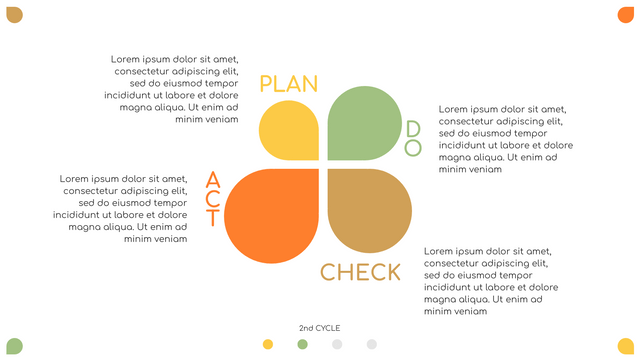

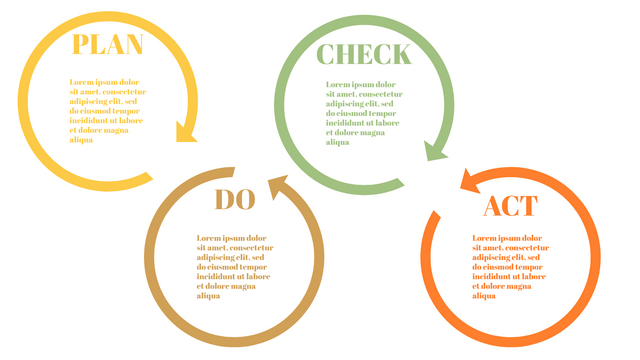

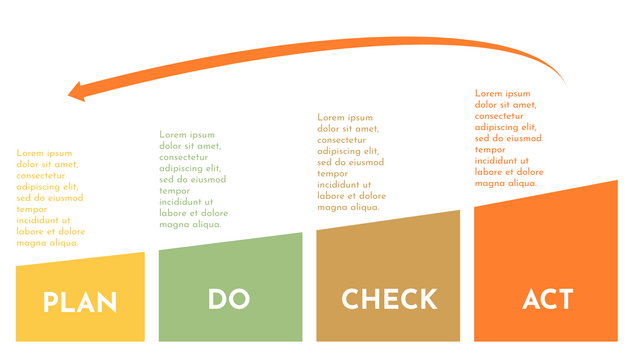

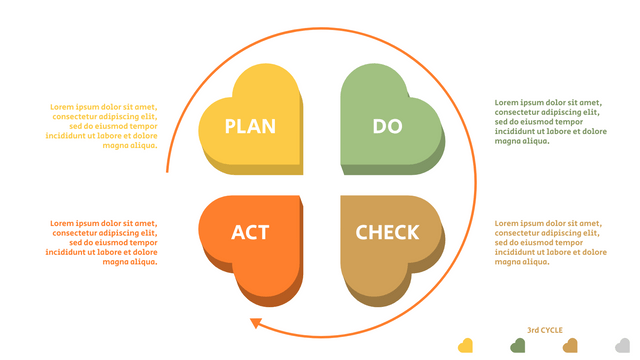

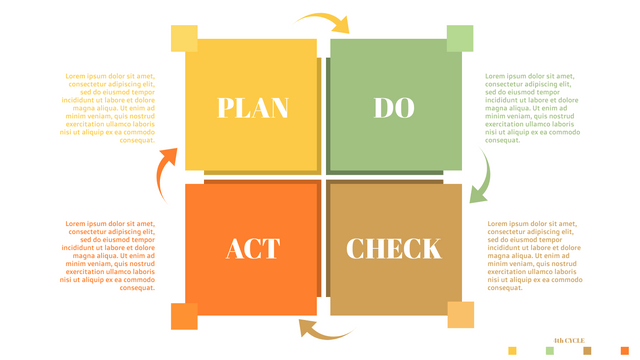

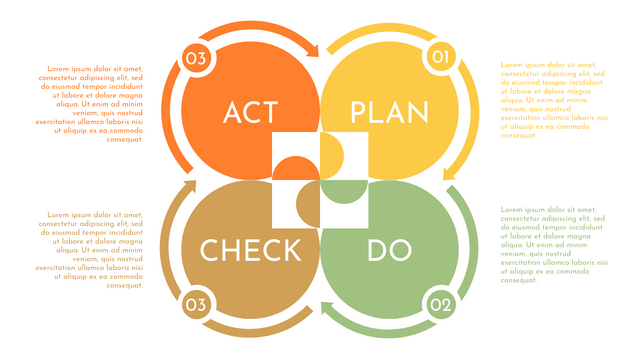

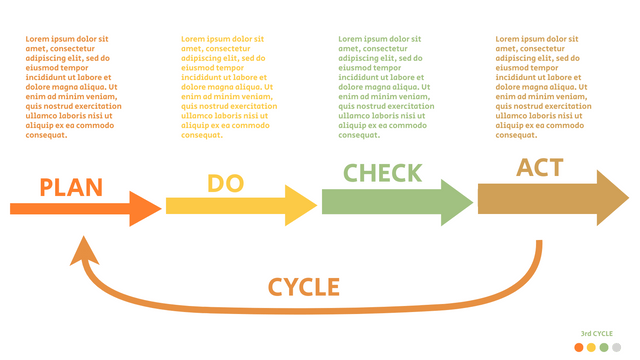

PDCA is the acronym of Plan, Do, Check, and Action. The PDCA cycle is a scientific process in which quality management is carried out in this order and is constantly cycled.

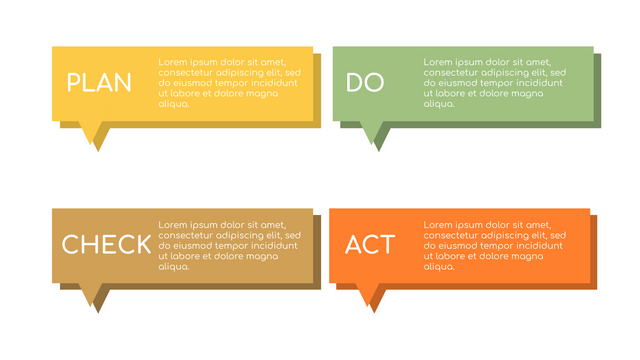

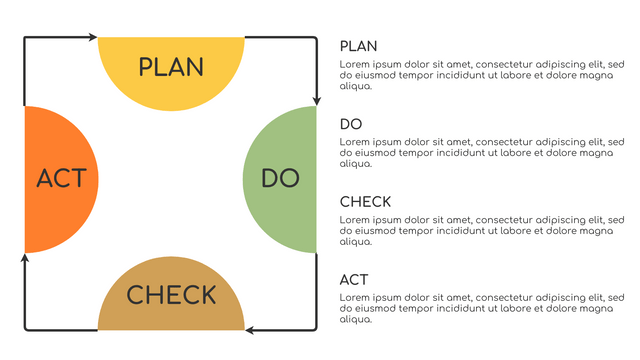

P ( plan ) plan, including the determination of policies and objectives, and the formulation of activity plans.

D ( Do ) is executed. According to the known information, specific methods, schemes and plan layouts are designed; then specific operations are carried out according to the design and layout to realize the contents of the plan.

C ( check ) check, summarize the results of the execution plan, distinguish which ones are right and which ones are wrong, clarify the effects, and find out the problems.

A ( Action ) a summary of the results of checks carried out at the science, to be sure of success stories, and be standardized; For unresolved issues, they should be submitted to the next PDCA cycle for resolution.

PDCA cycle is the scientific procedure and integral part of total quality management, lean method, six sigma and other methods. For example, the whole process of total quality management activities is the formulation and organization process of quality plan. This process is carried out in accordance with the PDCA cycle, is continuous, repeated operation. The PDCA cycle is not only applied to the quality management system, but also applicable to all progressive management work.