Humans are not machines. We will inevitably make mistakes in our work and life. In particular, mistakes are more likely to occur if you don't plan ahead and rely only on your thoughts and feelings. Therefore, if we can put some checkpoints at a certain point in the working process and verify the results according to the expected requirements enforced in the process, we can get the best results.

The Origin of PDCA

PDCA cycle, also known as Deming cycle, is a common management mode. This was the first PDCA cycle proposed by Walter A. Shewhart in 1930 and later expanded by American quality management expert Dr. Edwards Deming in 1950.

In the process of constantly improving the quality of products unearthed, widely publicized and used in TQM (Total Quality Management). Total quality management is a scientific process. The whole process of total quality management activities is the process of making and organizing quality plans. The process conforms to the PDCA cycle and runs continuously.

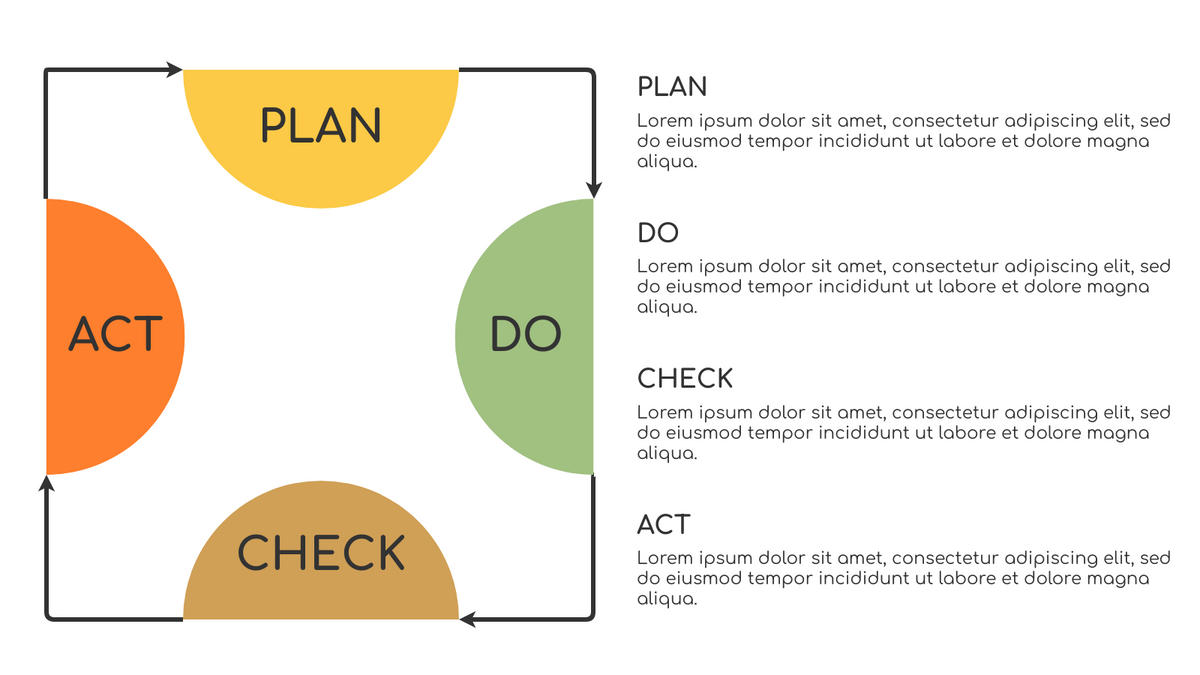

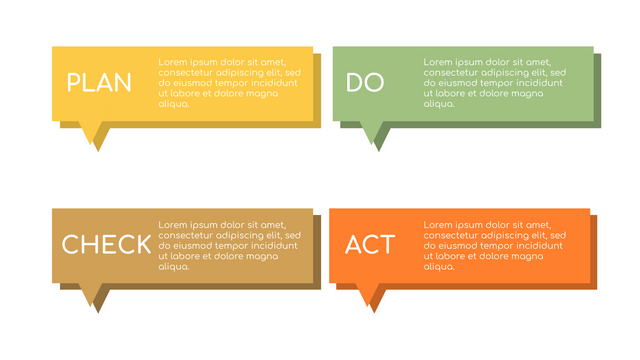

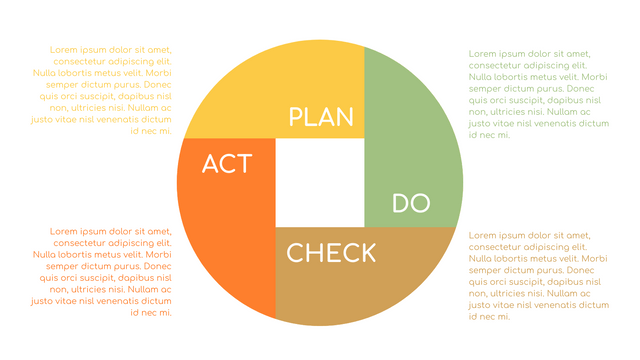

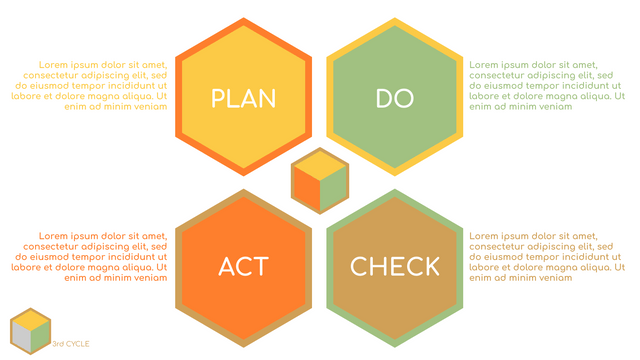

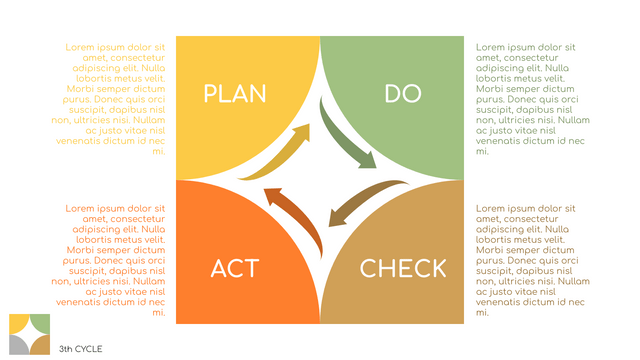

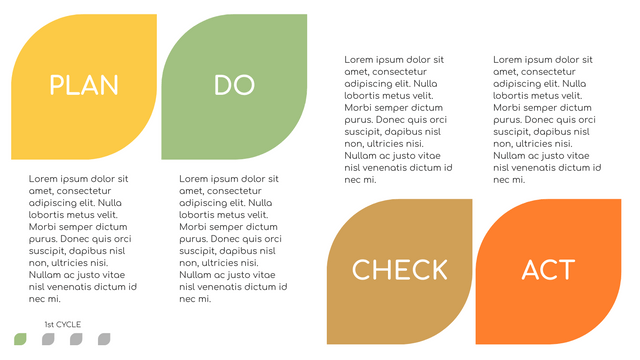

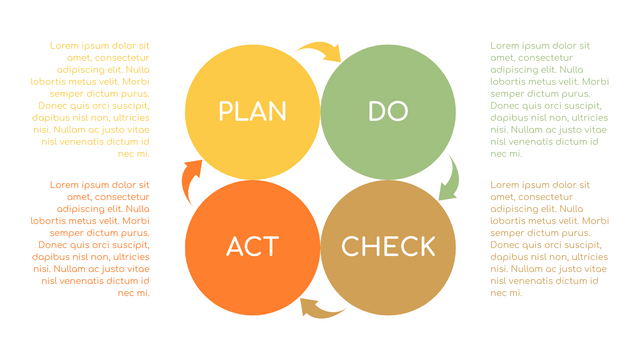

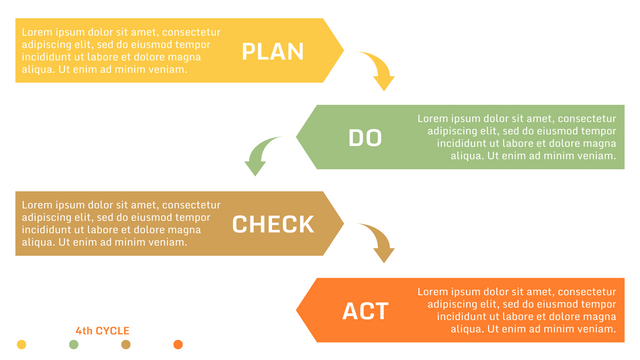

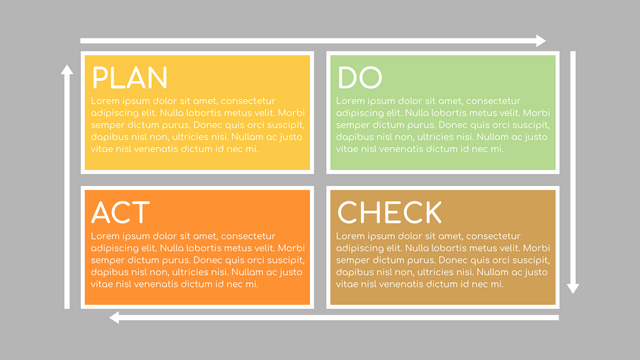

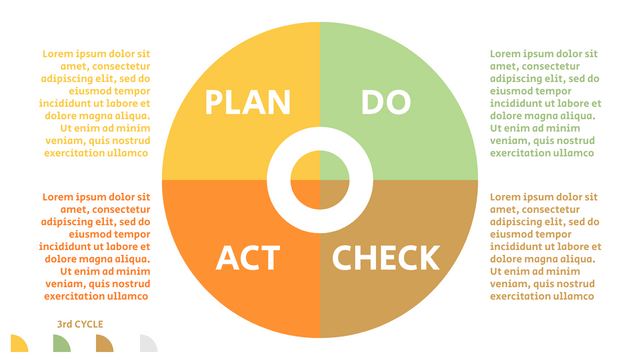

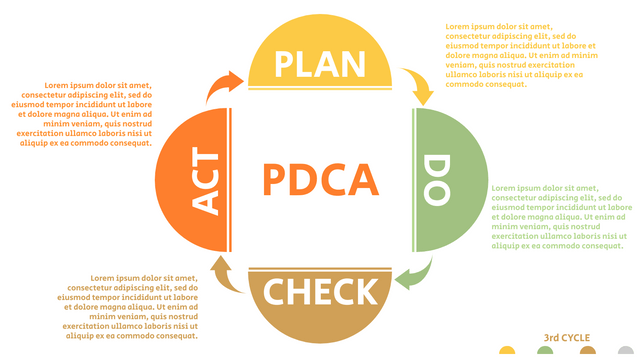

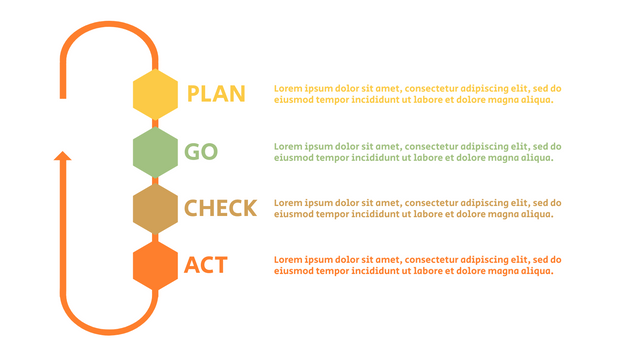

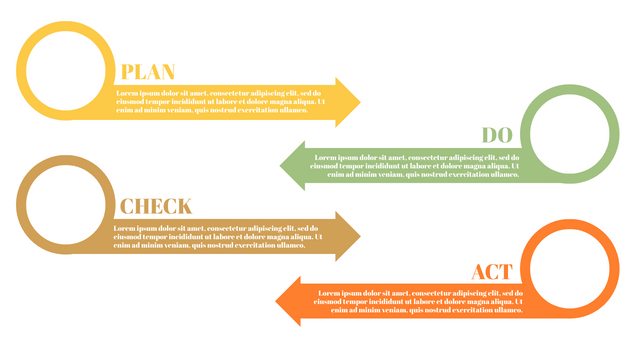

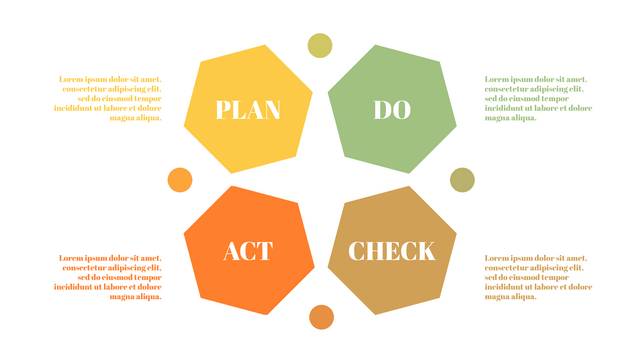

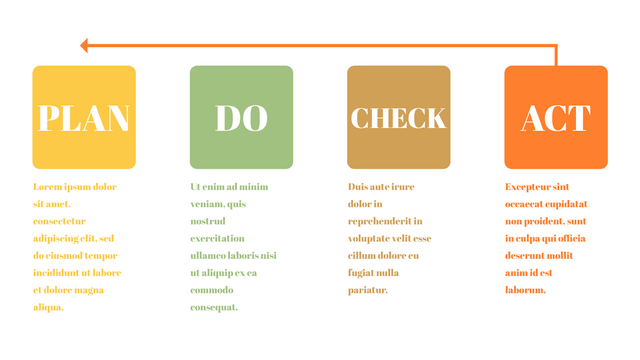

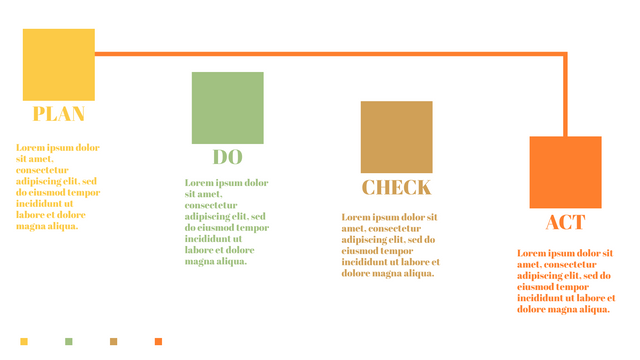

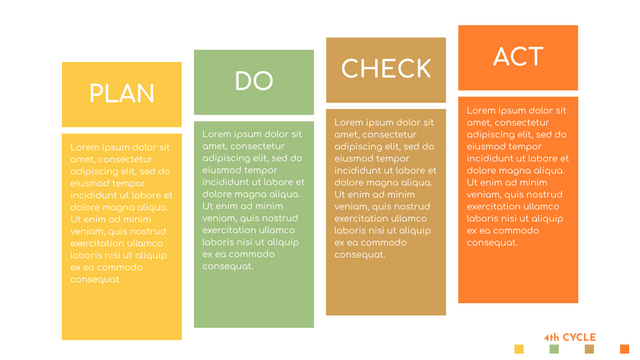

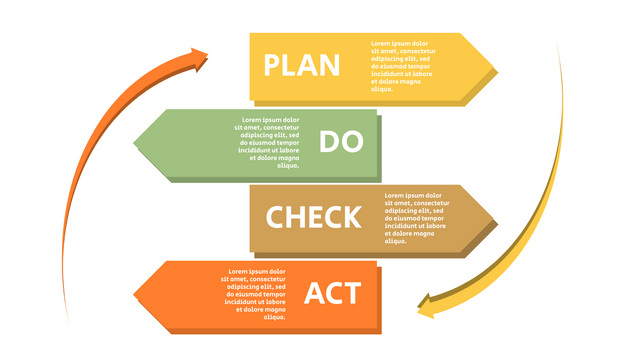

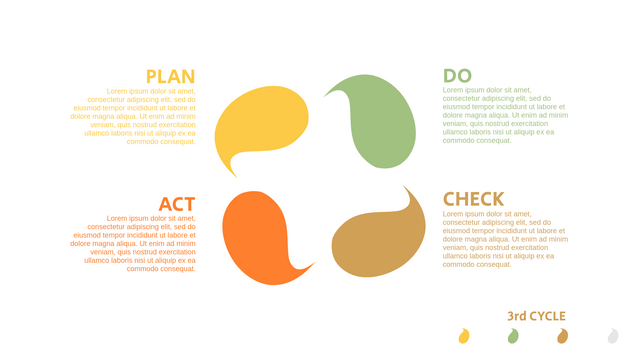

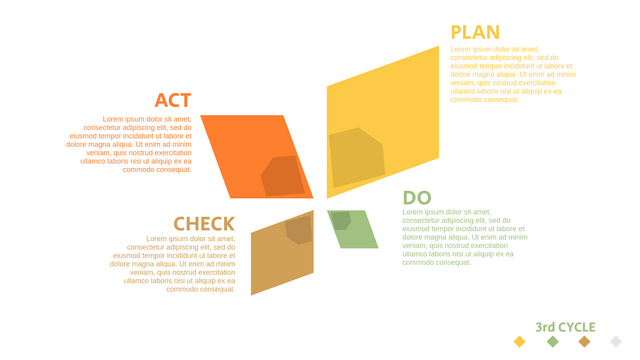

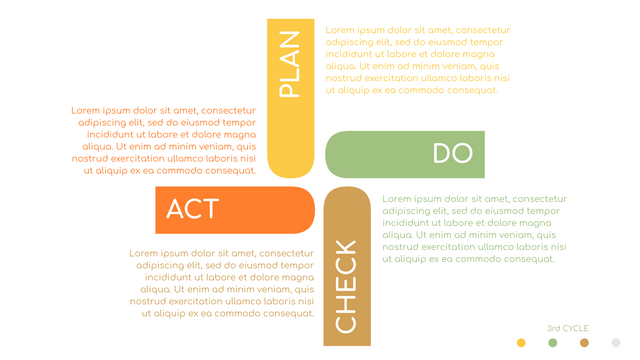

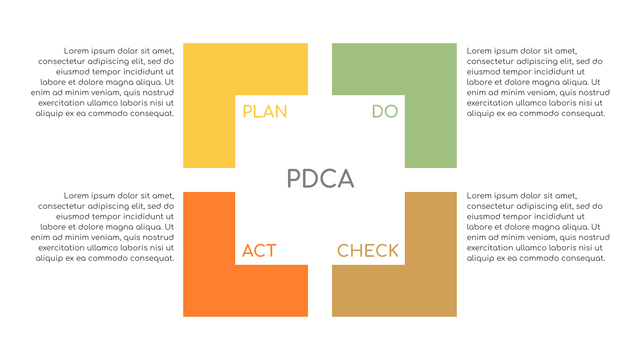

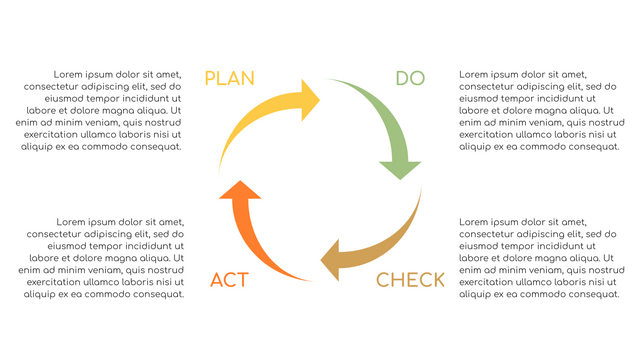

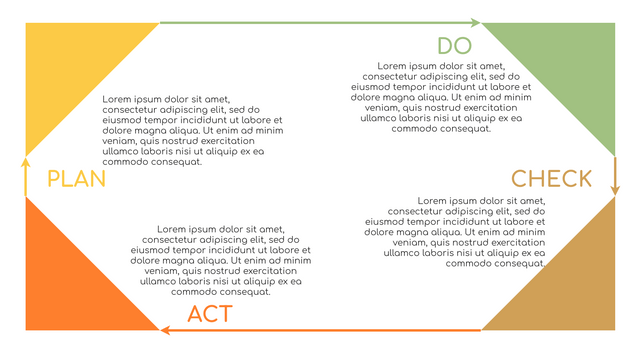

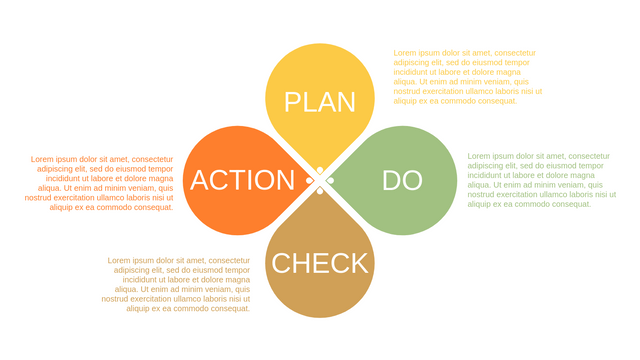

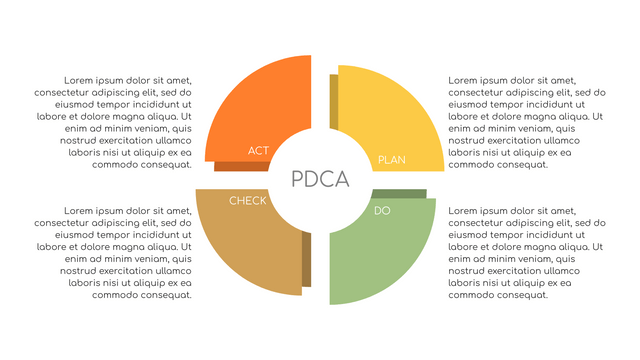

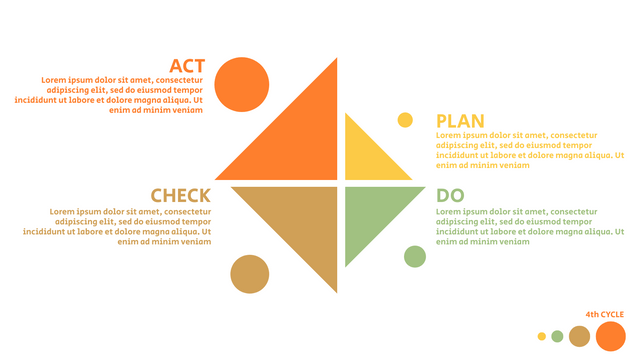

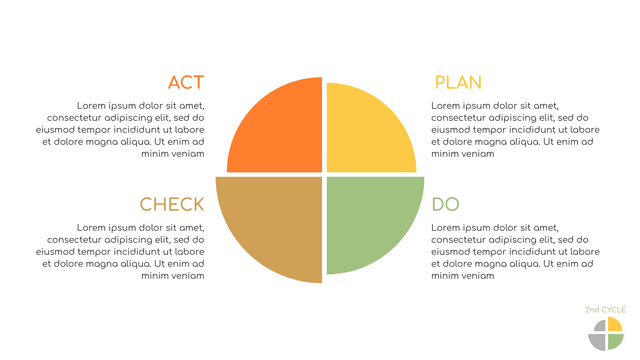

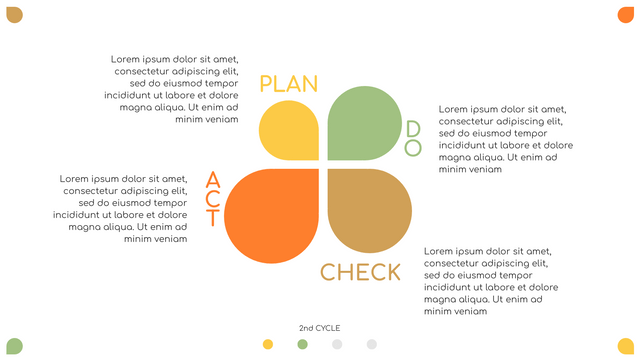

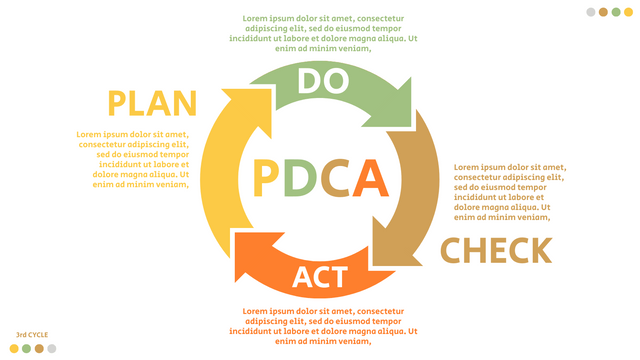

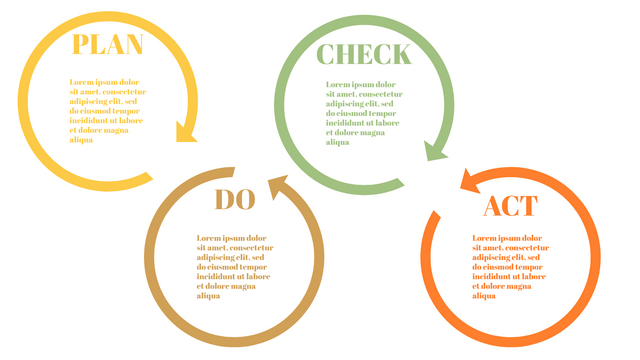

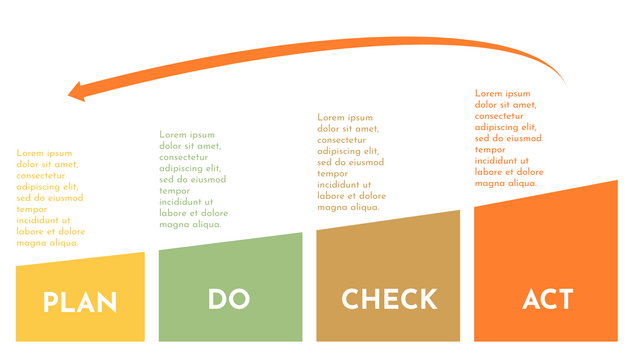

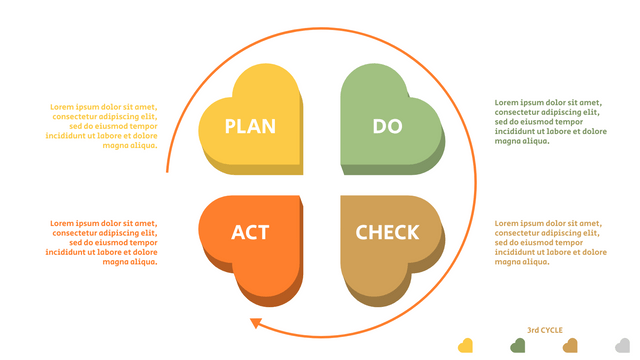

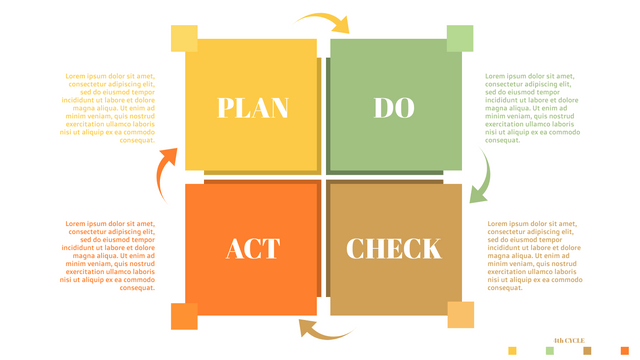

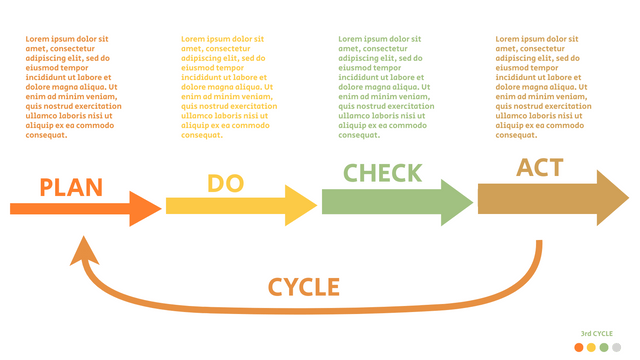

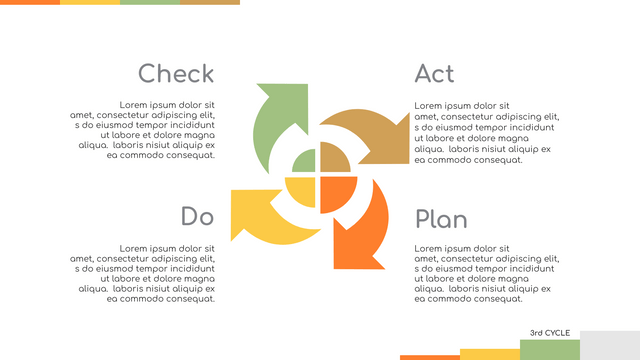

PDCA cycle is a kind of logical working process that makes any activity can be carried out effectively for any tasks from simple to complex. The four English letters P, D, C and A have the following meanings:

P (plan) -- plan. Including the determination of guidelines, objectives and the formulation of activity plans;

D (Do) -- Implement. Execution is the concrete operation to realize the content of the plan;

C (check) -- check. Summarize the results of the implementation plan, distinguish right from wrong, clarify the effect, and find problems;

A (action) -- action (or treatment). To summarize the results of the inspection processing, affirming the successful experience, and to standardize, or develop work instructions, to facilitate the future work.

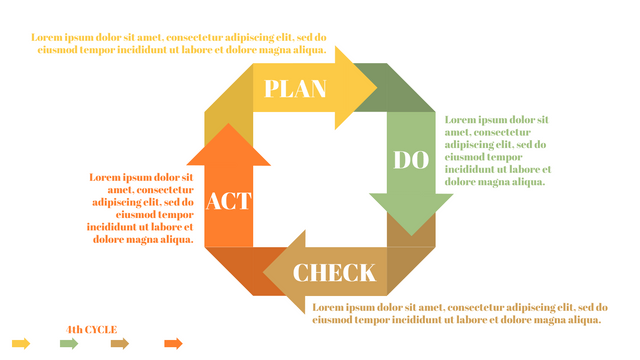

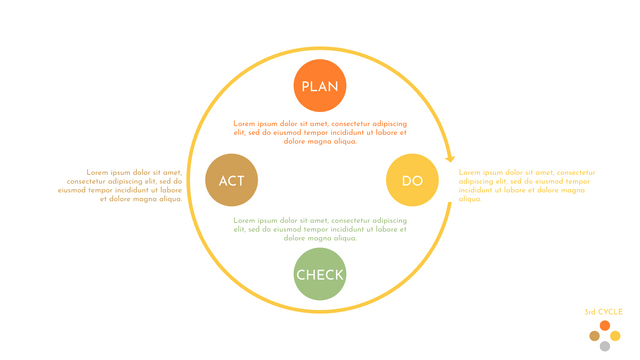

Continuous Improvement with PDCA

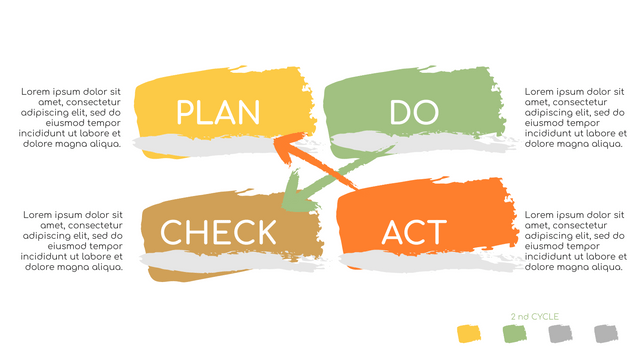

We can often learn from our failure to avoid it happening again. We can issues should be submitted carry forward the unresolved to the next PDCA cycle for resolution. PDCA cycles are climbing like stairs. When one cycle ends, the quality of production will be improved by one step, and then the next cycle will be formulated, and then run, improve again, and continue to advance and improve.