Dr. Edward Deming is considered by many to be the founder of modern quality management, who popularized PDCA based on the scientific method of problem solving. PDCA is an important part of lean method, quality management and many other fields. It is commonly referred to as the Deming wheel, the Shewhart cycle, the Deming cycle, and the PDCA cycle.

It is shown to be efficient for:

Discover better work process

Seek for better work efficient and cut cost

Teamwork motivation by brainstorming and problem-solving

Exploring a variety of alternatives to challenges

Seek for gradual improvement

Avoiding resource wastage

Support in TQM and lean and Agile approaches

What is PDCA Approach?

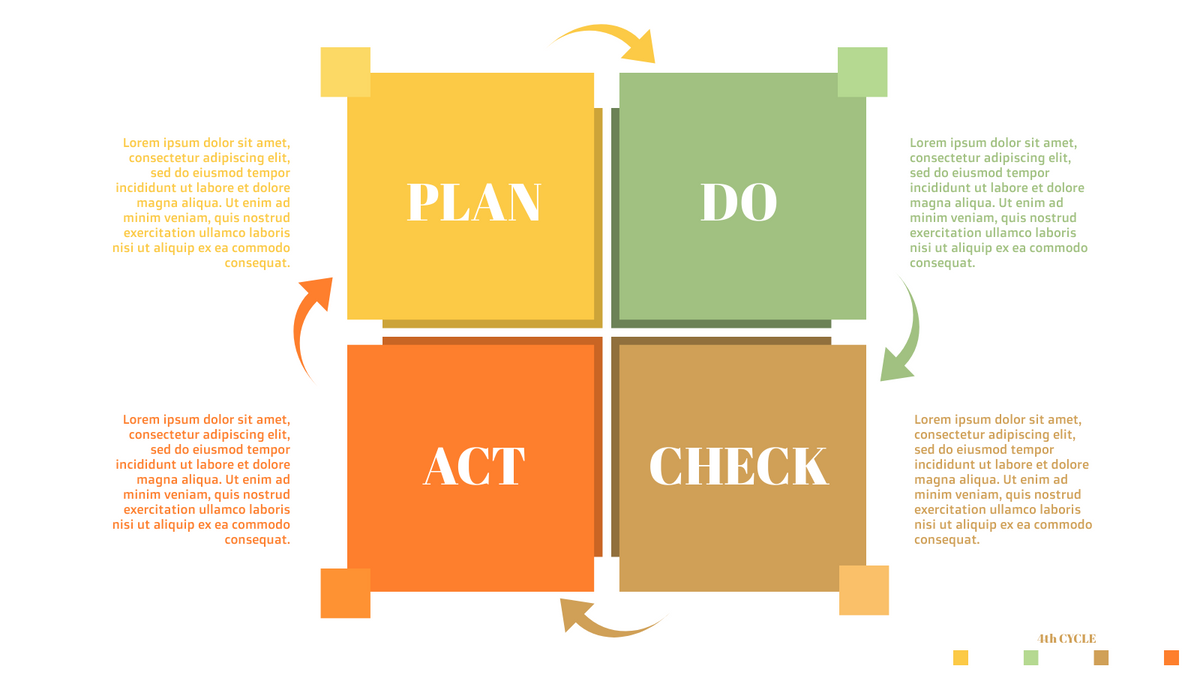

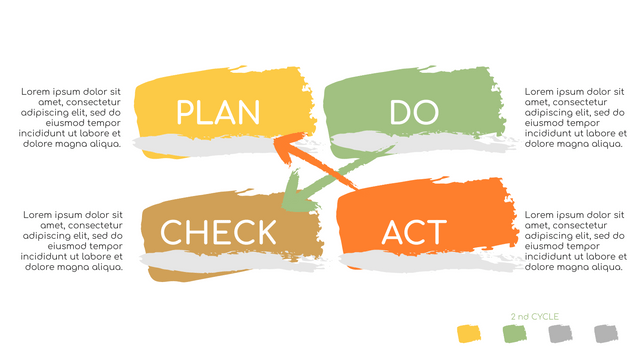

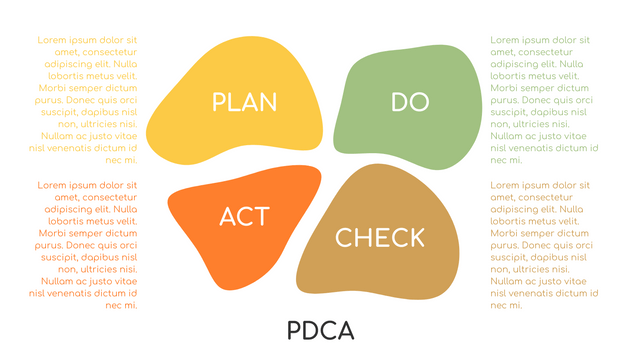

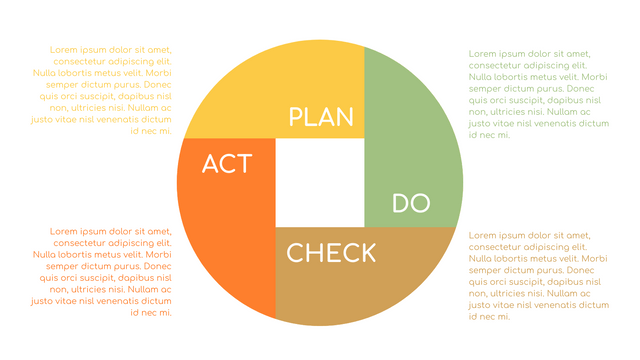

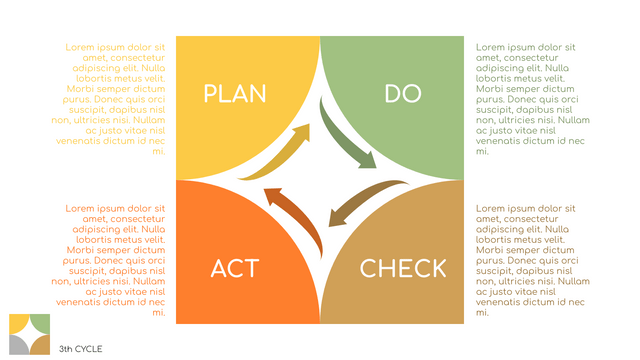

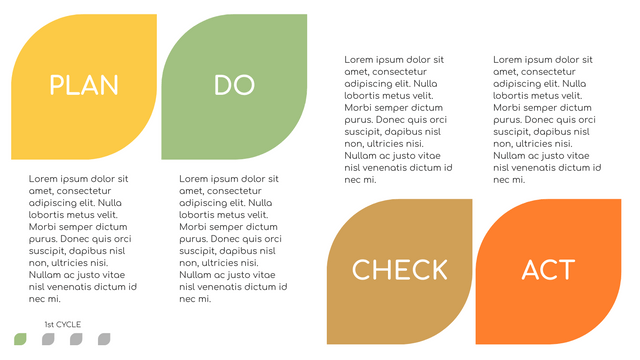

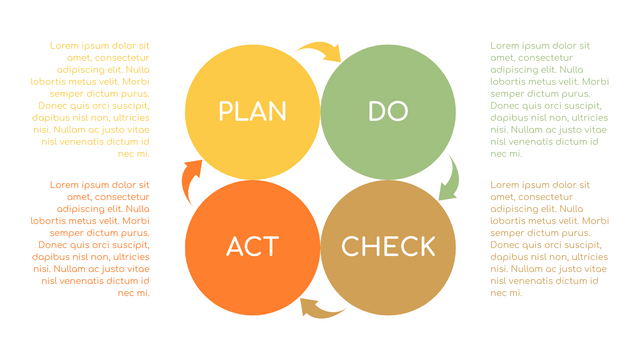

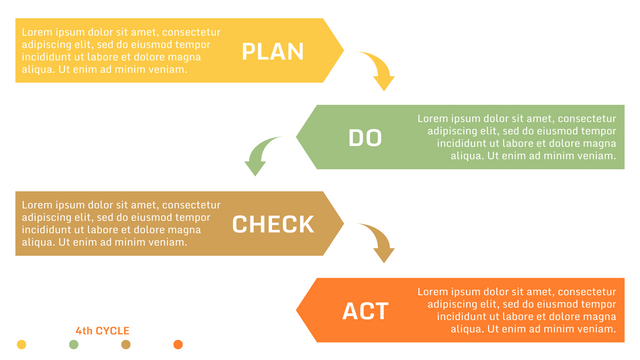

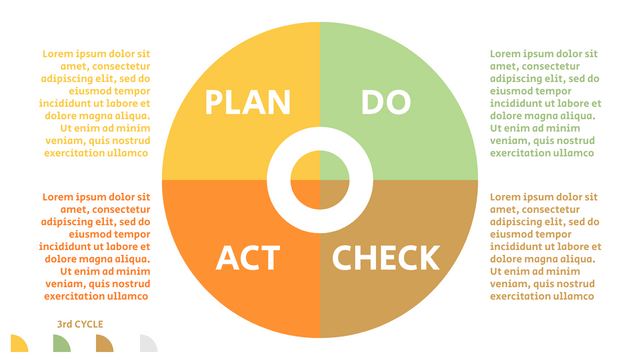

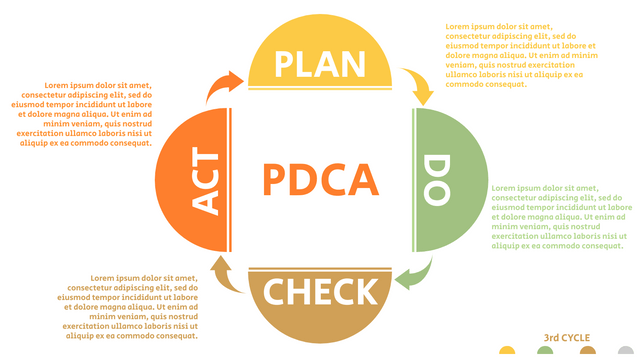

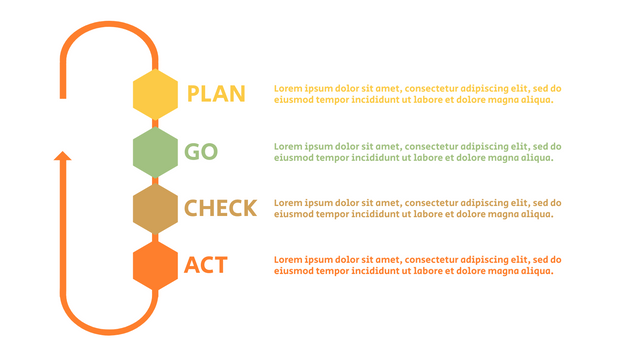

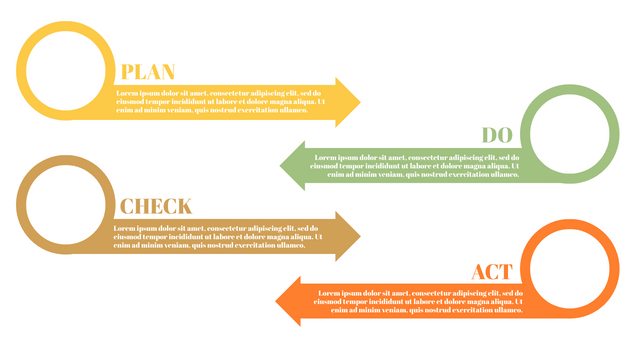

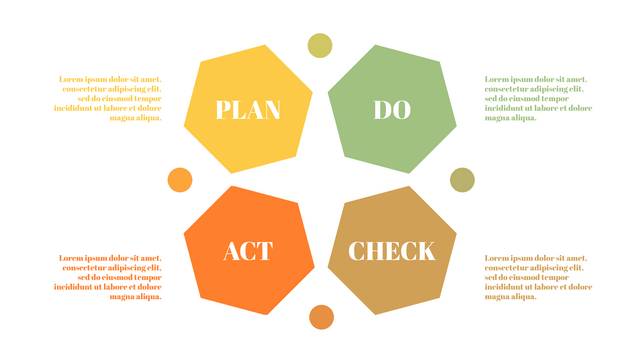

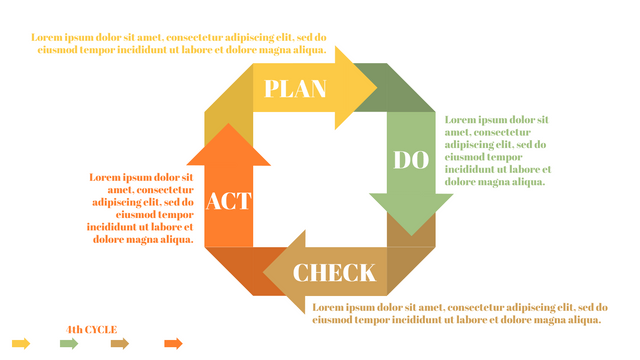

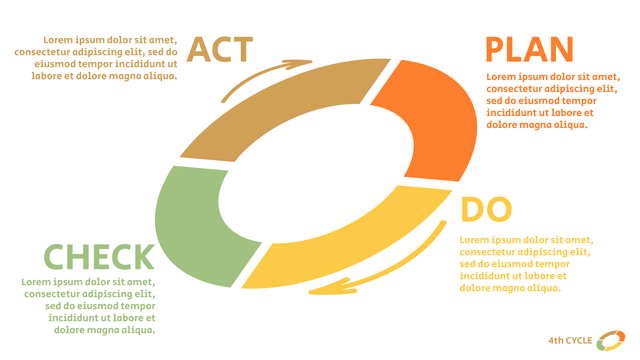

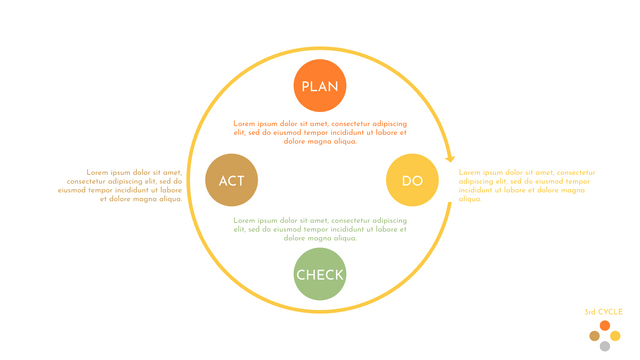

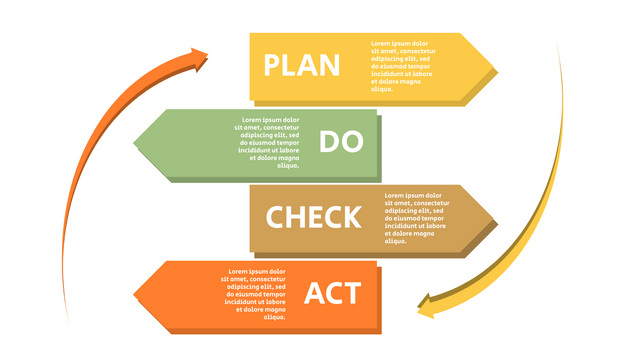

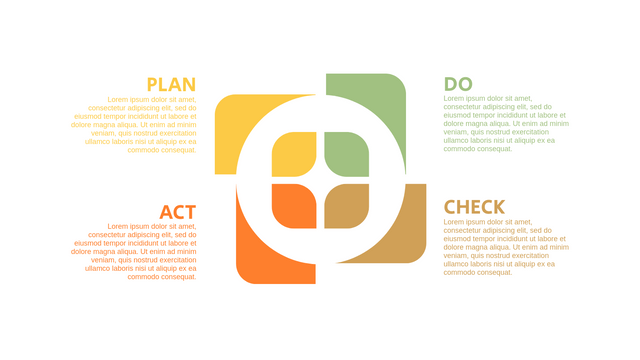

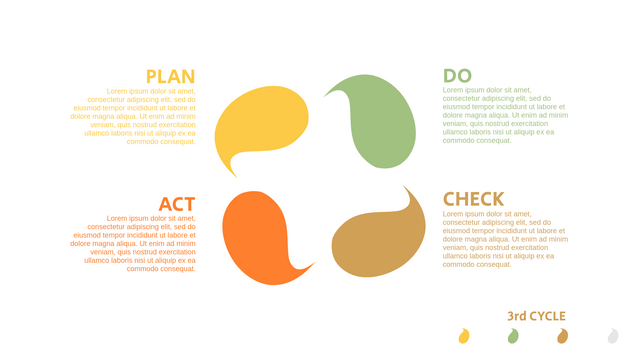

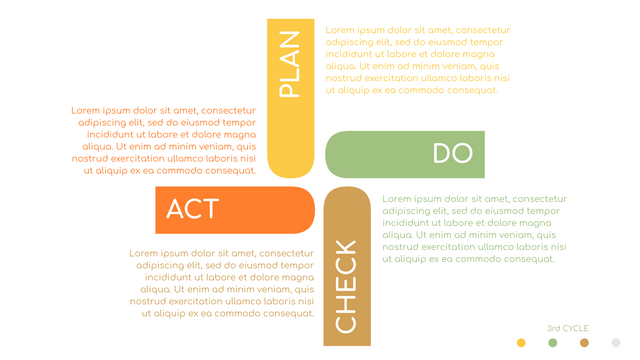

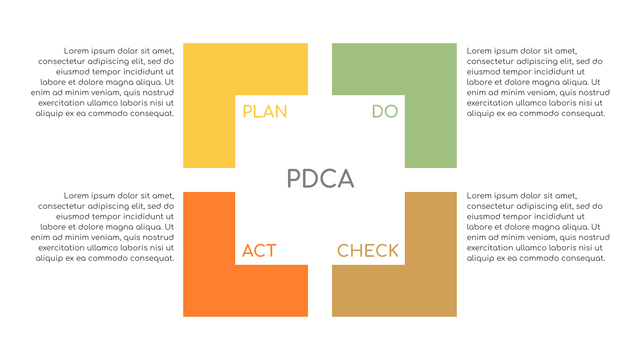

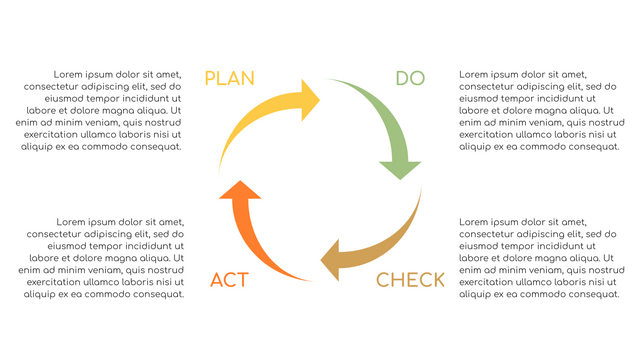

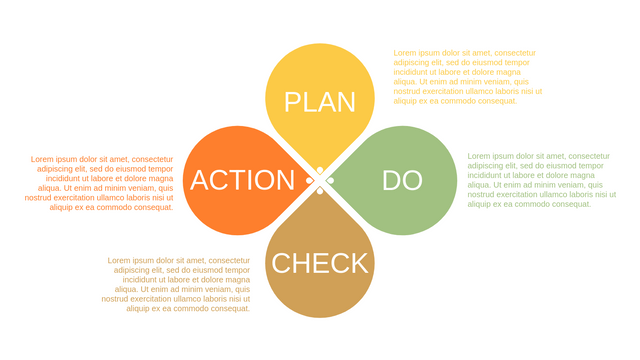

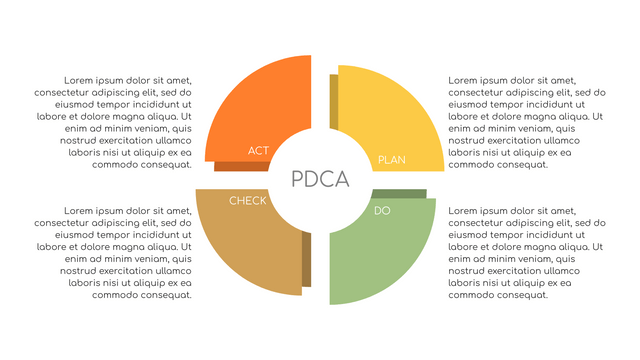

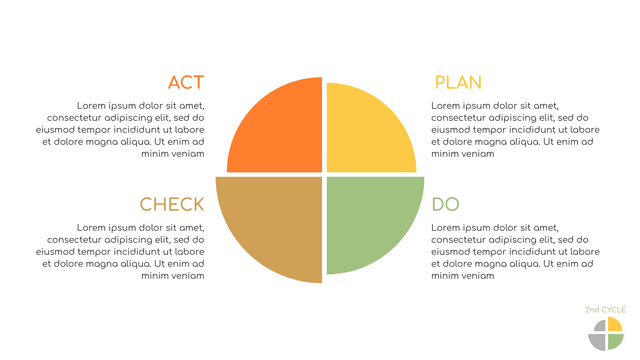

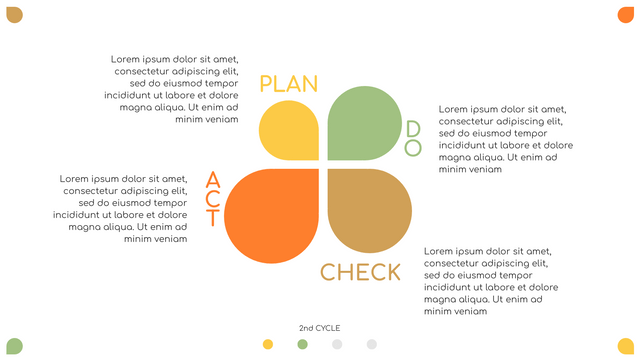

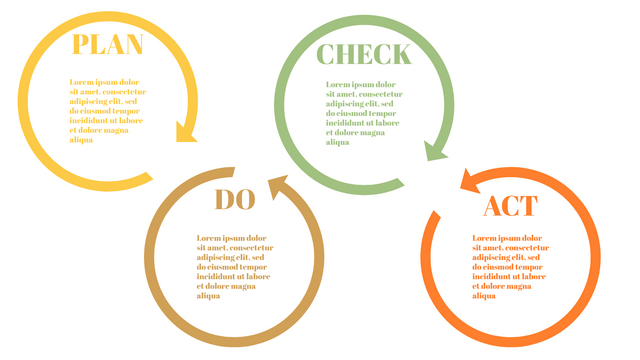

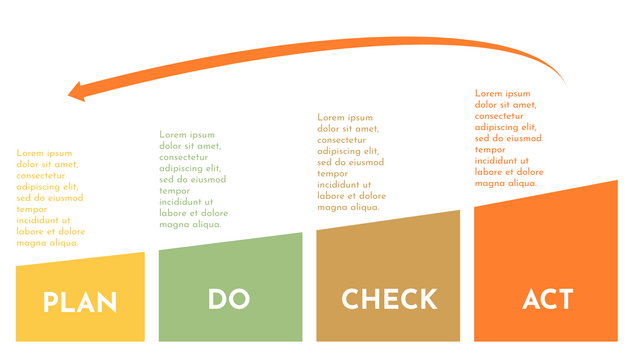

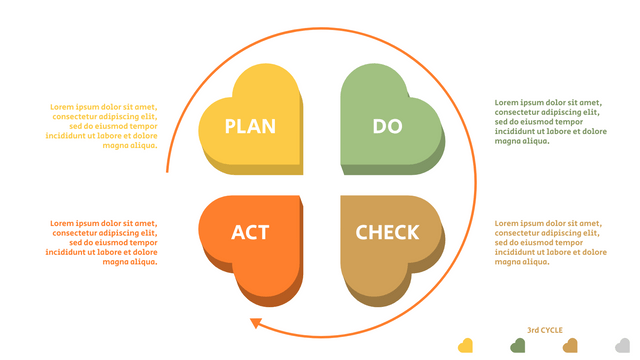

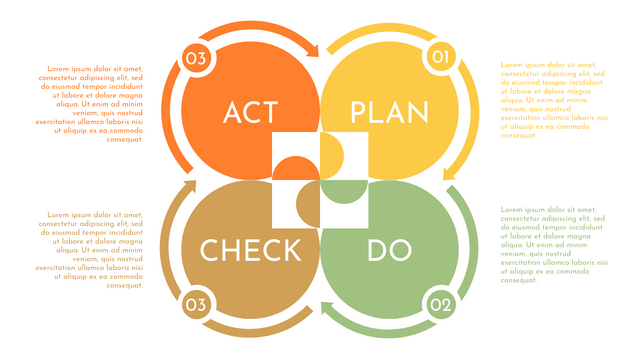

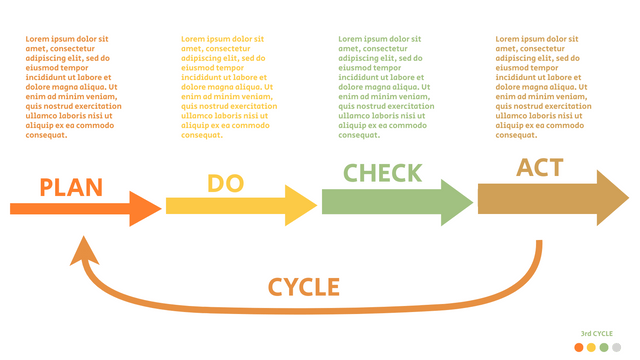

The PDCA cycle (Plan-Do-Check-Action) is an iterative, four-stage management approach for continuous improvement of processes, products, or services to solve problems. As part of a never-ending continuous improvement process of constant learning and development, the four stages that form the PDCA cycle can be repeated over and over.

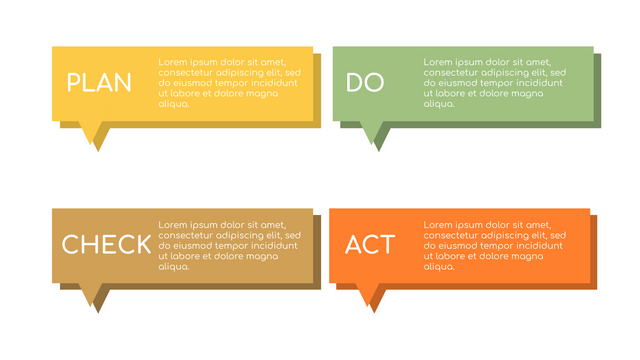

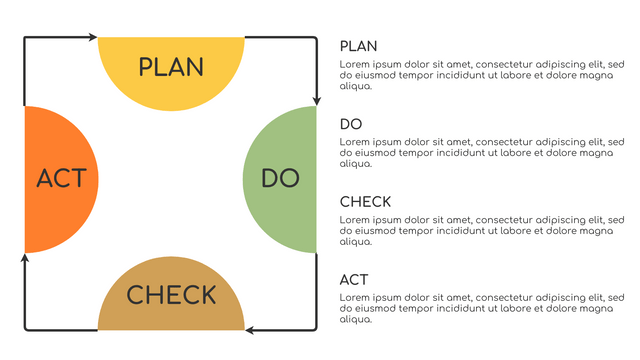

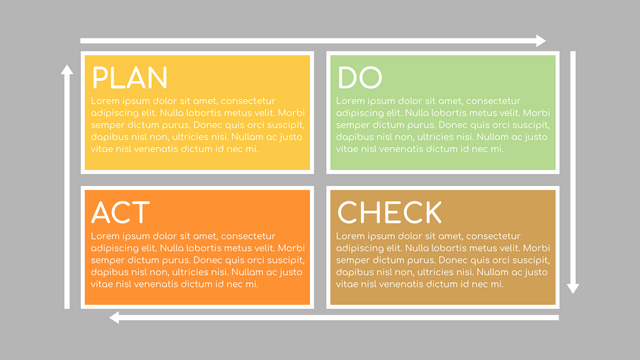

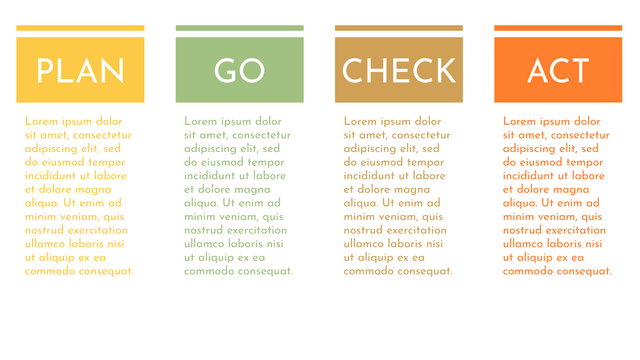

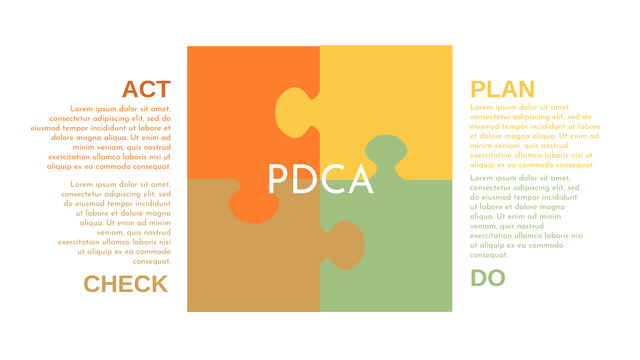

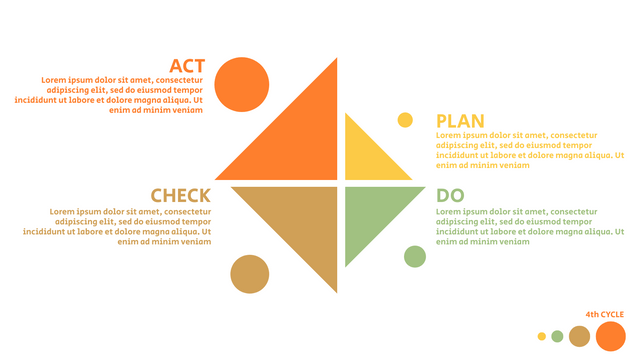

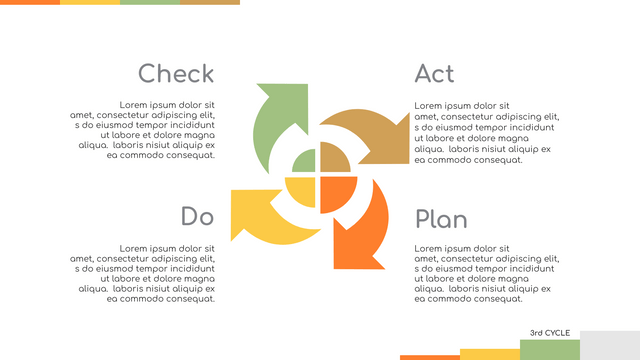

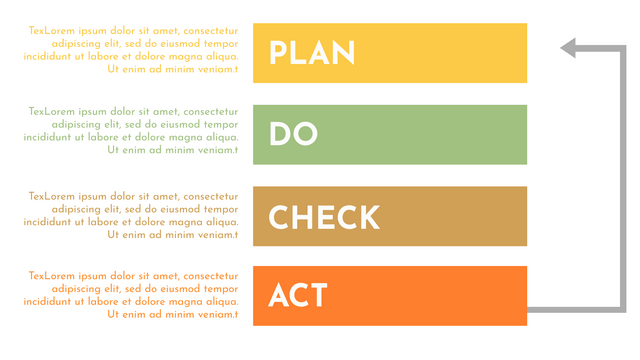

The 4 Stages of the PDCA are:

Plan - Think about where you are now and where you need to be. Identify opportunities and plan for change - Record the plan.

Do - Implement changes in small scale research as a pilot project.

Check - Look at the tests, review and analyze the results and determine what you learned.

Act - Take action based on what you learned in the learning steps: If the change doesn't work, cycle with a different plan again. If successful, incorporate what you learned from the test into the broader changes. Use what you learn to plan for new improvements and restart the cycle.