This elementary and often effective approach to problem-solving promotes deep thinking through questioning, and can be adapted quickly and applied to most problems. For example, asking “Why?” may be a favorite technique of your three-year-old child in driving you crazy, but it could teach you a valuable problem-solving technique.

“If you don’t ask the right questions, you don’t get the right answers. A question asked in the right way often points to its answer. Asking questions is the ABC of diagnosis. Only the inquiring mind solves problems.” – Edward Hodnett

The “5 Whys” is a simple problem-solving technique that helps you to get to the root of a problem quickly, which was originally developed by Sakichi Toyota. It was used within the Toyota Motor Corporation during the evolution of its manufacturing methodologies. It is a critical component of problem-solving training, delivered as part of the induction into the Toyota Production System.

How to Conduct 5 Whys Analysis?

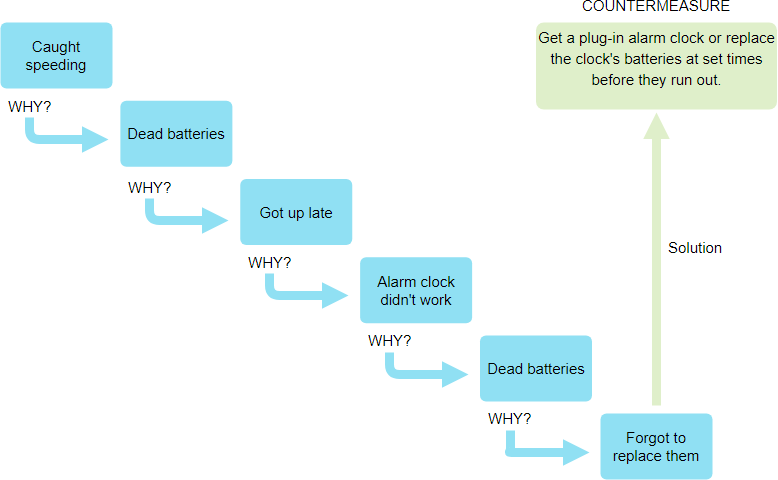

When you’re looking to solve a problem, start at the result and work backward (toward the root cause), continually asking: “Why?” You’ll need to repeat this over and over until the root cause of the problem becomes apparent.

The 5 Whys strategy involves looking at any problem and asking: “Why?” and “What caused this problem?” Very often, the answer to the first “why” will prompt another “why” and the answer to the second “why” will prompt another and so on; hence the name the 5 Whys strategy.

The 5 Whys exercise is vastly improved when applied by a team and there are five basic steps to conducting it:

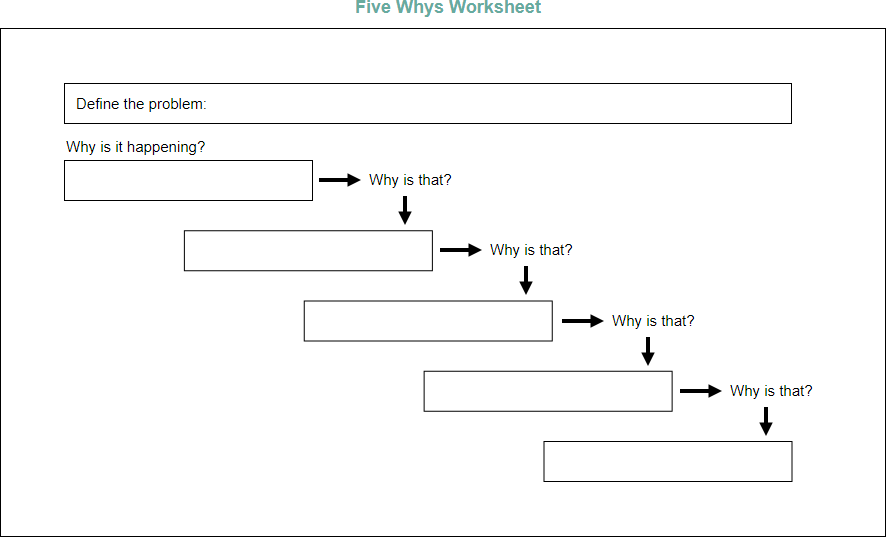

- Write down the specific problem. Writing the issue helps you formalize the problem and describe it completely. It also helps a team focus on the same problem.

- Ask “Why” the problem happens and write the answer down below the problem.

- If the answer you just provided doesn’t identify the root cause of the problem that you wrote down in Step 1, ask “Why” again and write that answer down.

- Loopback to step 3 until the team is in agreement that the problem’s root cause is identified. Again, this may take fewer or more times than five Whys.

- After settling on the most probable root cause of the problem and obtaining confirmation of the logic behind the analysis, develop appropriate corrective actions to remove the root cause from the system.

5 Whys Example

The vehicle will not start. (The problem)

- Why? – The battery is dead. (First why)

- Why? – The alternator is not functioning. (Second why)

- Why? – The alternator belt has broken. (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

Note: A 5 Whys analysis sometime could be taken further to a sixth, seventh, or higher level, but five iterations of asking why are generally sufficient to get to a root cause.

5-Whys Criticisms

Here are each of the criticisms as listed on the Wikipedia:

- Stopping at symptoms, not the root cause

- Limited by the investigator’s knowledge.

- Not asking the right Why questions.

- Not repeatable – Different people build different 5 Whys.

- The tendency to isolate a single root cause