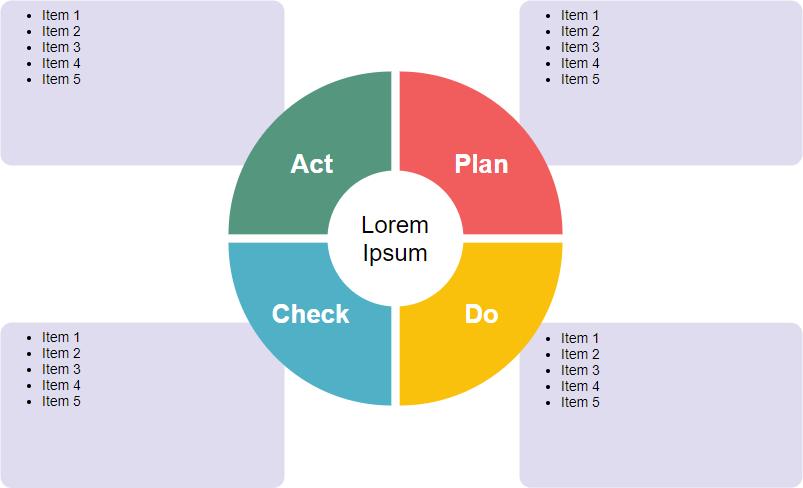

A PDCA cycle based on the scientific method of proposing a change in a process, implementing the change, measuring the results, and taking appropriate action. It also is known as the Deming Cycle or Deming Wheel after W. Edwards Deming, who introduced the concept in Japan in the 1950s. PDCA cycle is a four-stage model providing a framework for developing, testing and implementing changes leading to quality improvement.

Plan: Determine goals for a process and needed changes to achieve them.

Do: Implement the changes.

Check: Evaluate the results in terms of performance.

Act: Standardize and stabilize the change or begin the cycle again, depending on the results.

PDCA is an approach that emphasizes, once improvements have been identified and implemented, we should then seek out additional ways of making further improvements and that this process should be continuous.

When can we use the PDCA cycle?

- When starting a new Quality Improvement project

- When implementing change

- When improving or developing a new design for a process or service

- As a model for continuous improvement

- When planning data collection to verify and prioritize problems or root causes

- It is essential to know what you want to achieve, how you will measure improvement and be explicit about the idea to be tested.

Edwards Deming’s 14 Points

In addition to the PDCA cycle, Deming had also offered 14 key principles for management for transforming business effectiveness published in his book “Out of the Crisis” in 1982.

- Create constancy of purpose for improving products and services.

- Adopt the new philosophy.

- Cease dependence on inspection to achieve quality.

- End the practice of awarding business on price alone; instead, minimize total cost by working with a single supplier.

- Improve constantly and forever every process for planning, production, and service.

- Institute training on the job.

- Adopt and institute leadership.

- Drive out fear.

- Break down barriers between staff areas.

- Eliminate slogans, exhortations, and targets for the workforce.

- Eliminate numerical quotas for the workforce and numerical goals for management.

- Remove barriers that rob people of pride of workmanship, and eliminate the annual rating or merit system.

- Institute a vigorous program of education and self-improvement for everyone.

- Put everybody in the company to work accomplishing the transformation.