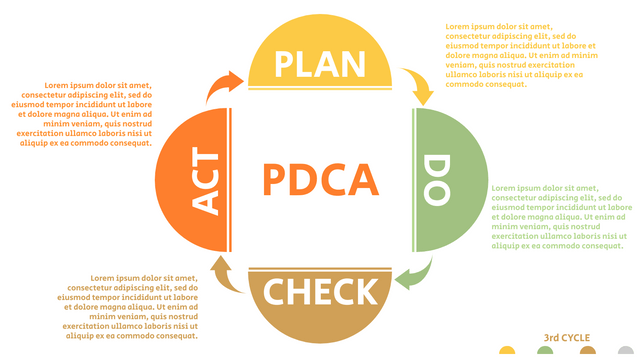

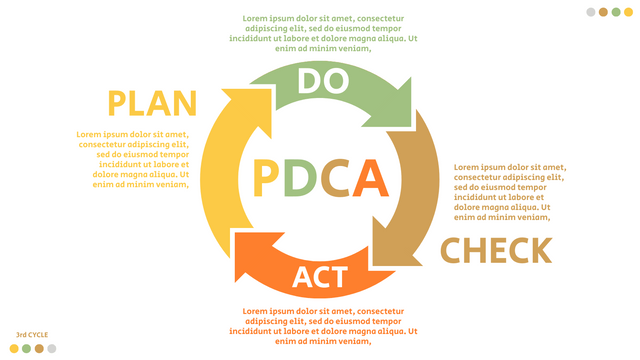

Analyzing quality and trying to improve it may be the main purpose behind improving business processes. Deming's goal is to apply scientific methods to business processes. He actually proposed this model through the so-called Deming cycle (PDCA), or also known as Deming Cycle or Deming Wheel).

The Deming Wheel

Deming's background as an engineer gave him a thorough understanding of industrial processes and a serious attempt to regulate operations to ensure large-scale operations. By studying mathematical physics, he was able to contribute to the development of statistical science. For example, the U.S. Census Bureau and the Bureau of Labor Statistics still use Deming's sampling technique.

What is the Deming Cycle?

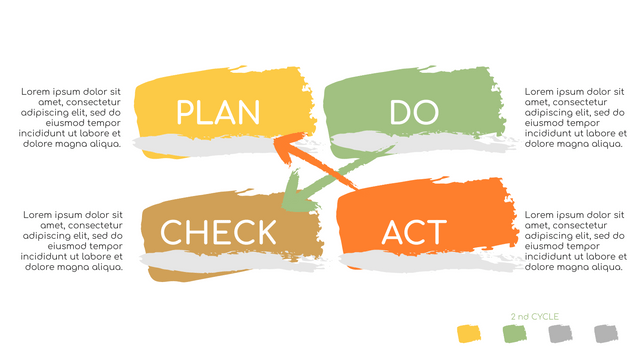

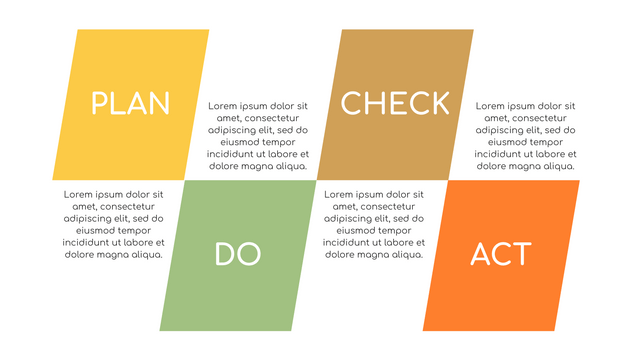

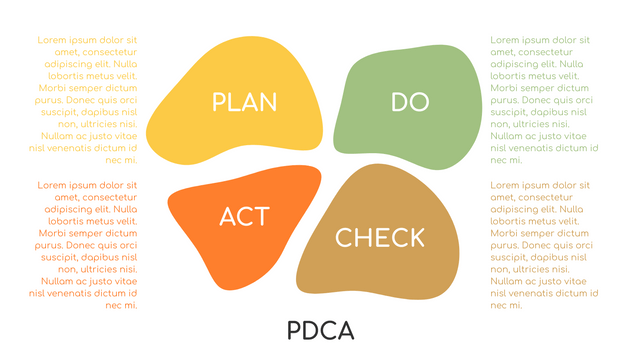

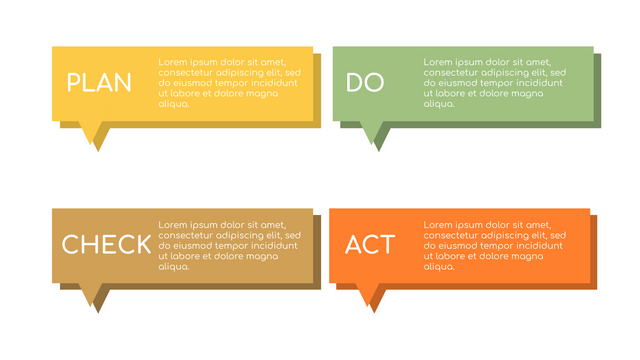

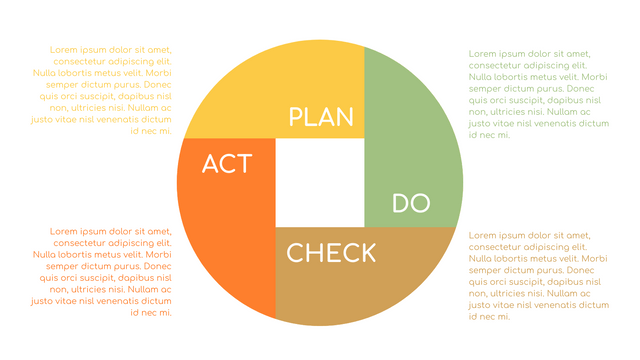

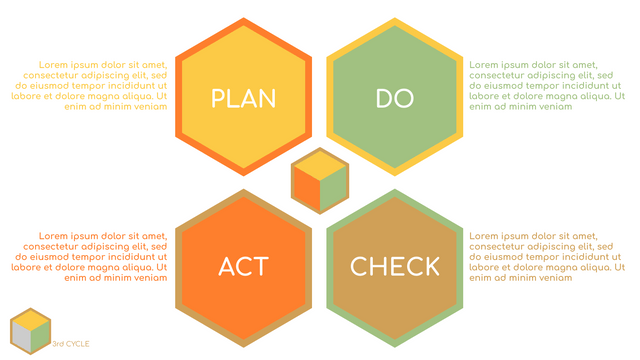

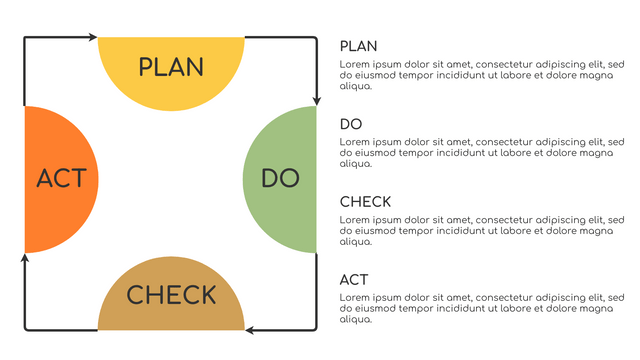

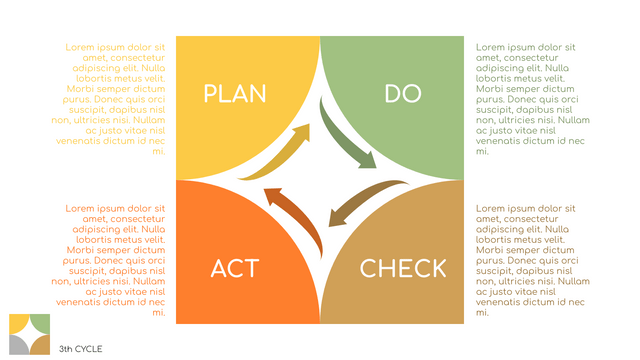

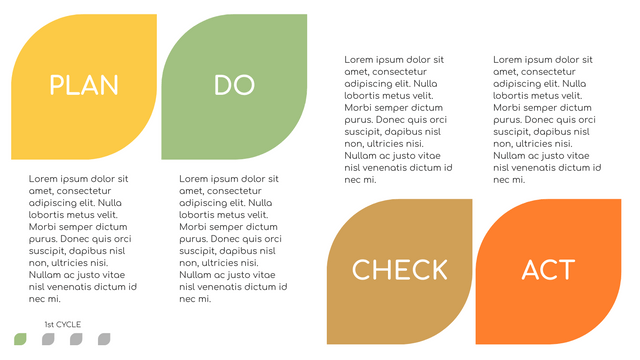

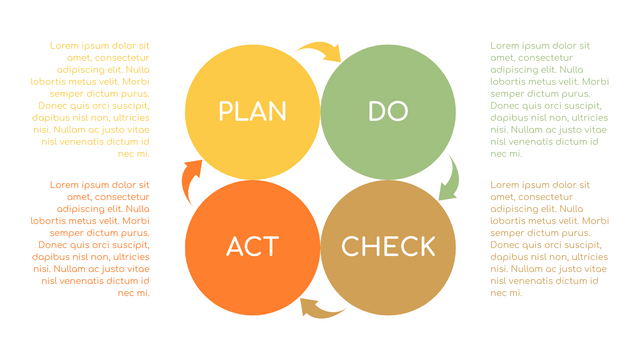

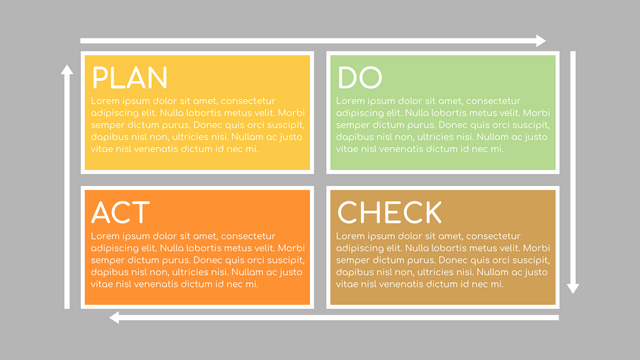

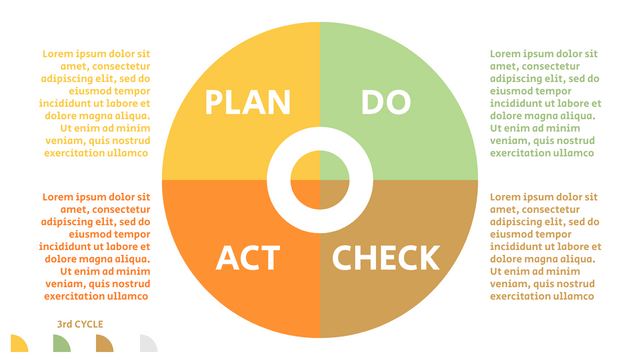

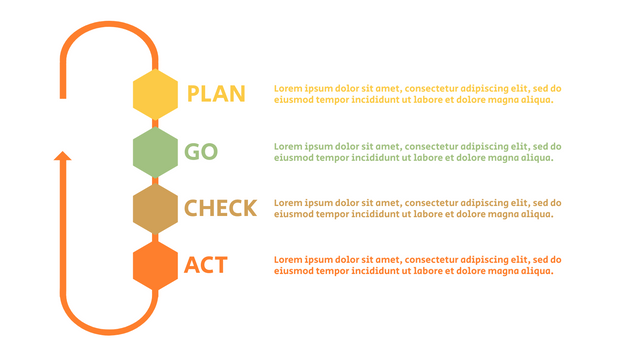

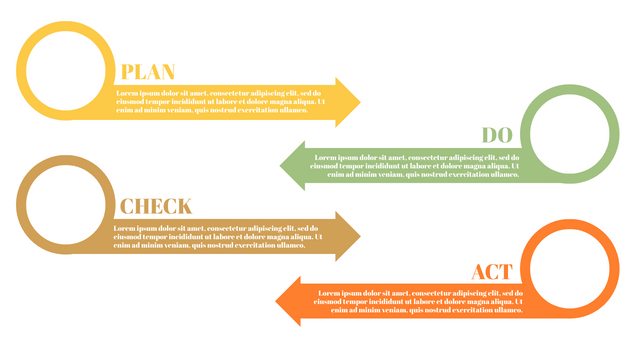

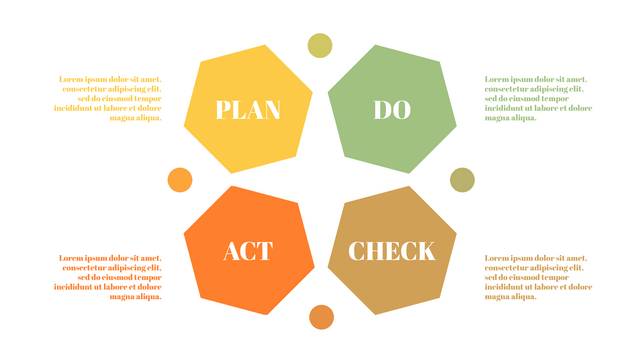

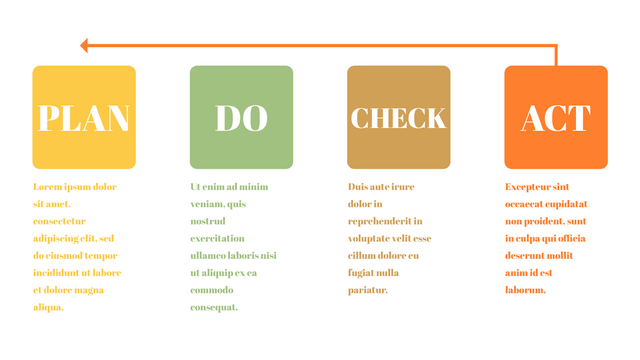

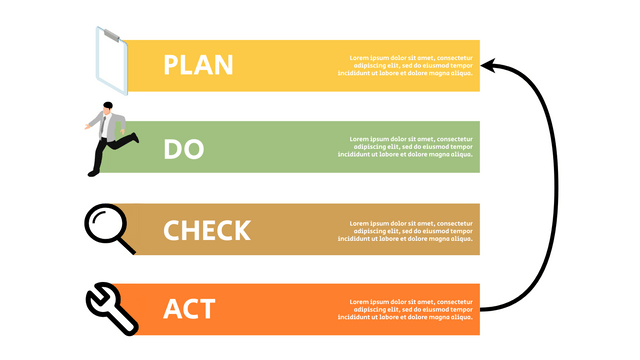

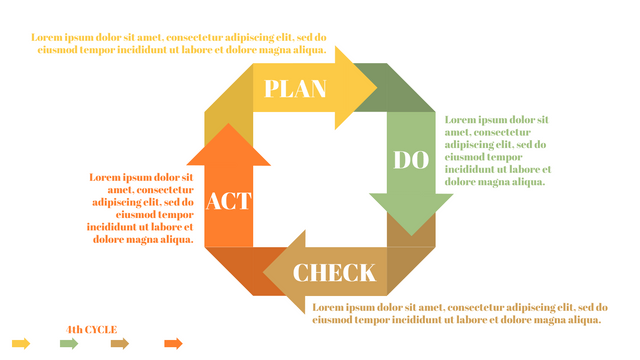

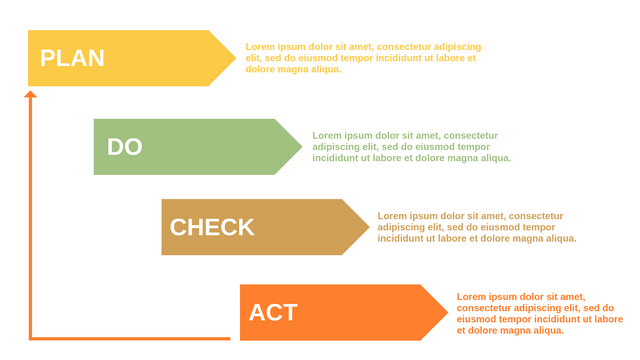

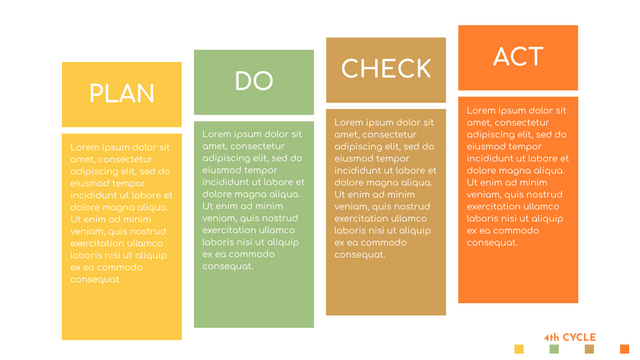

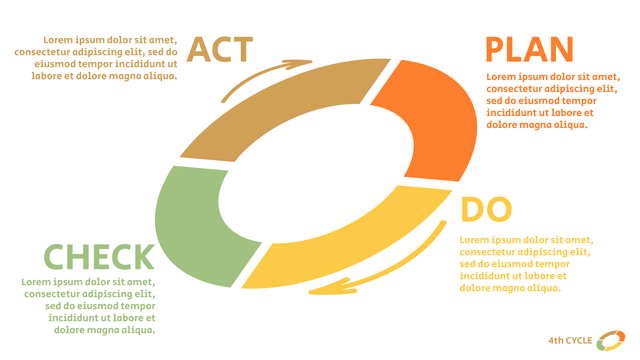

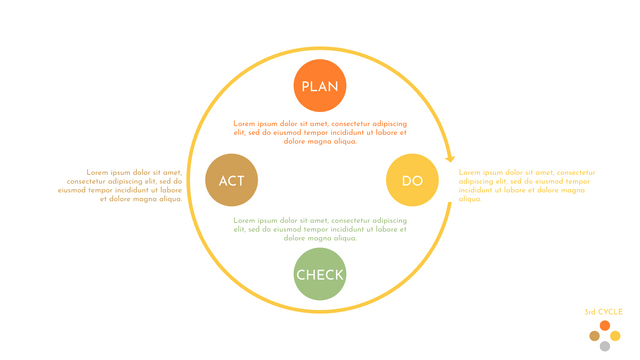

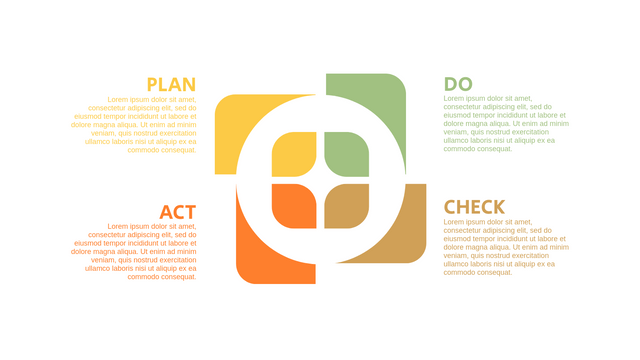

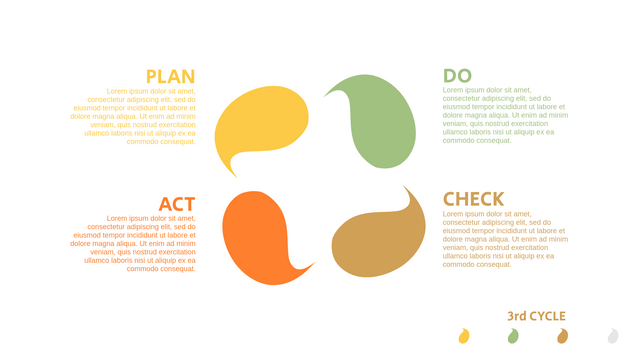

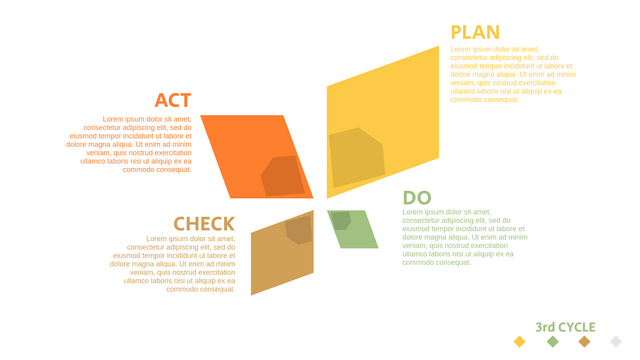

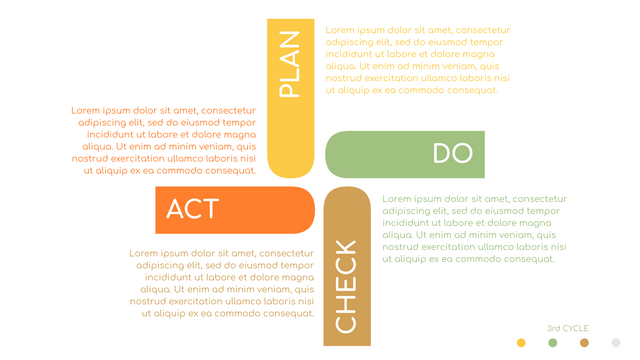

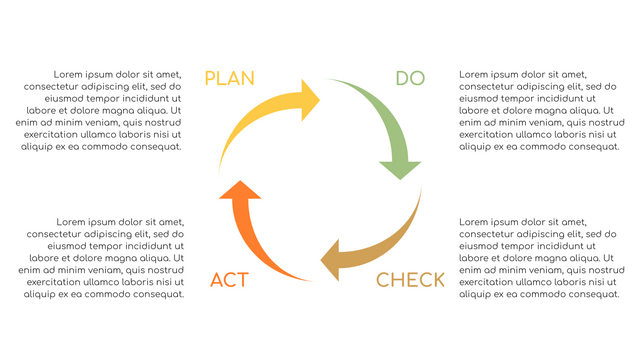

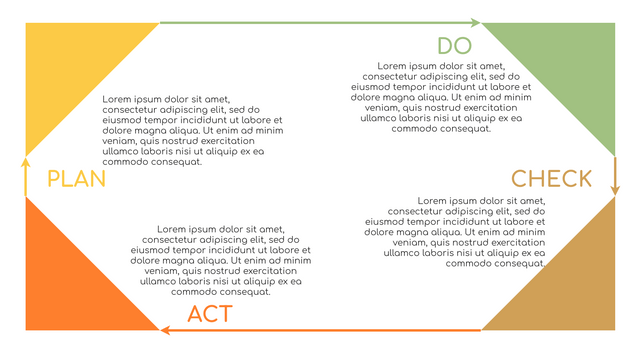

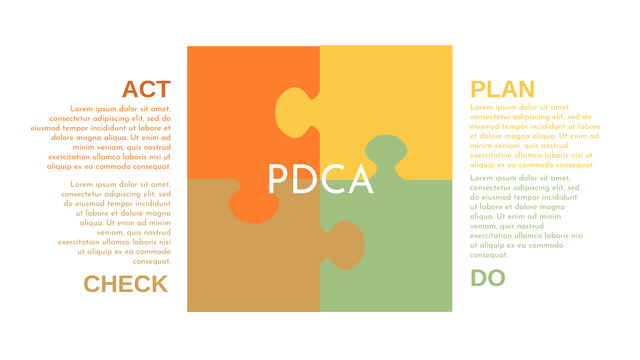

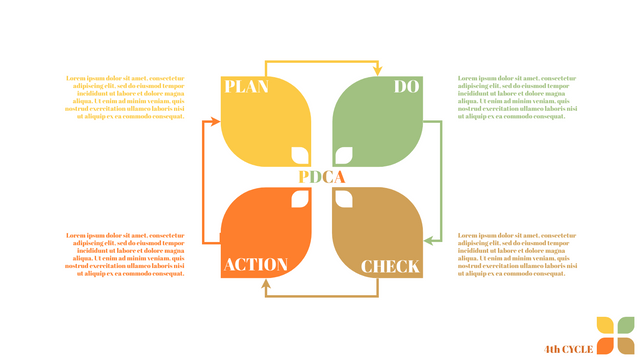

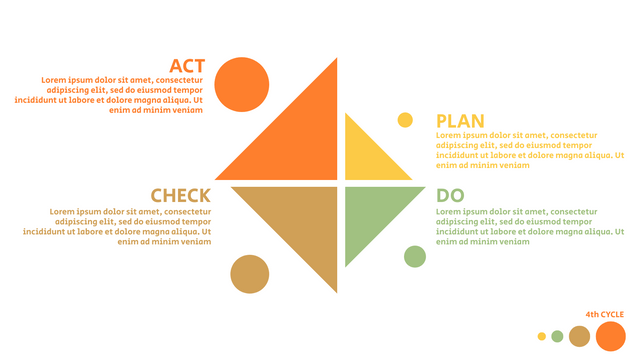

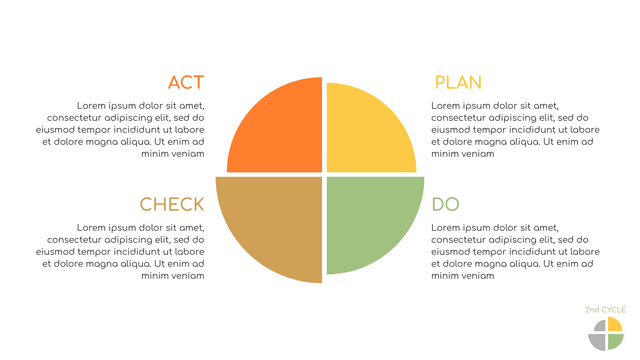

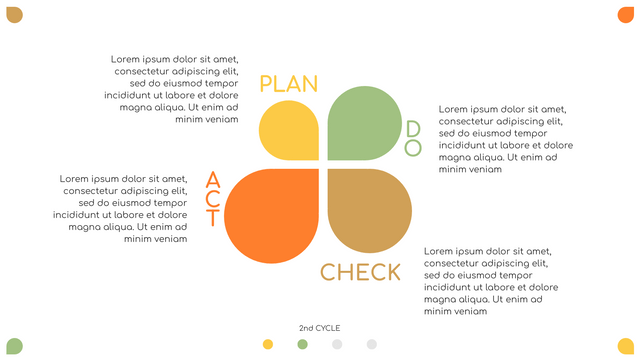

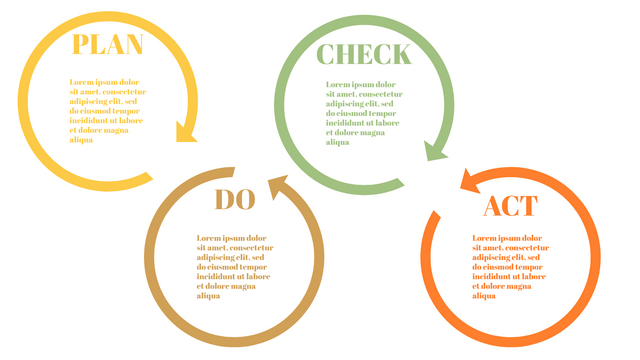

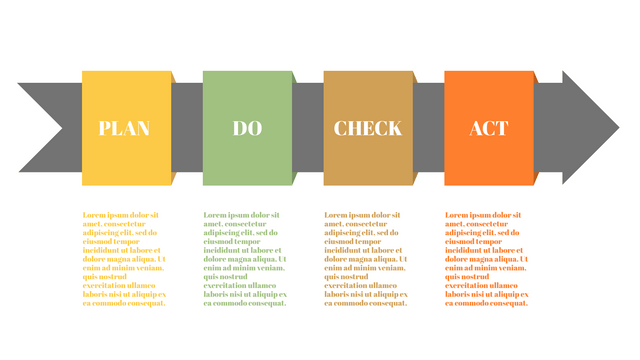

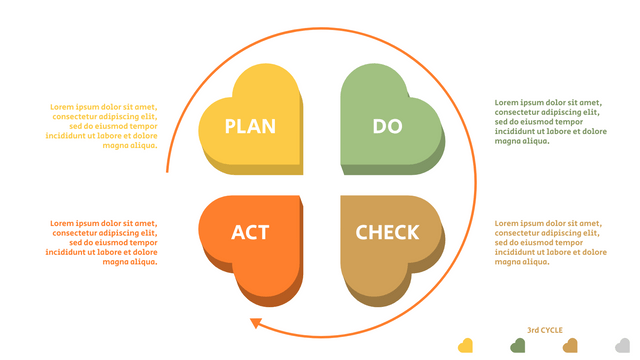

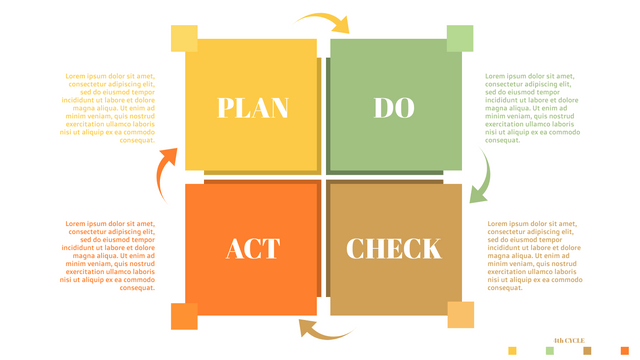

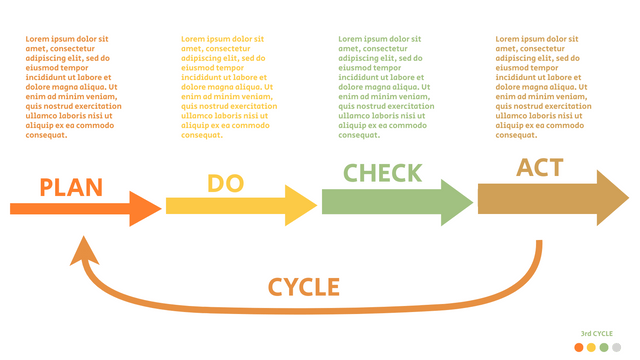

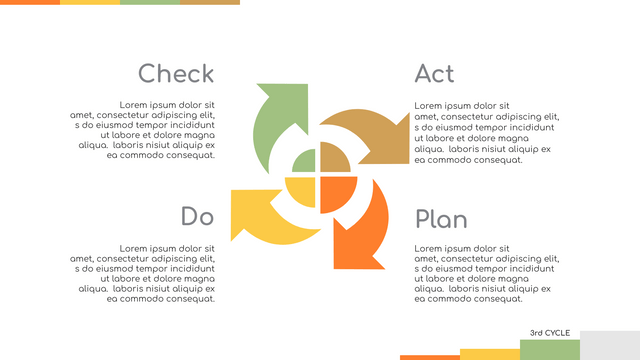

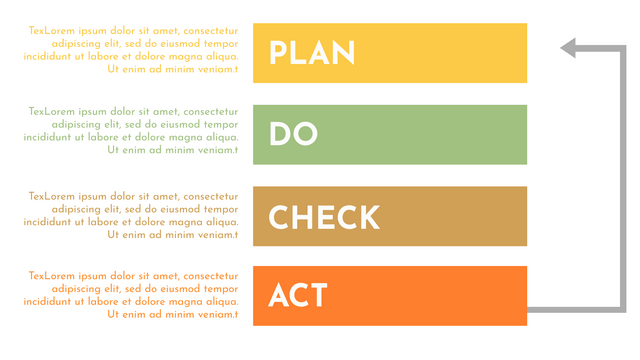

The Deming cycle is a model for continuous quality improvement, consisting of a logical sequence of four key stages:

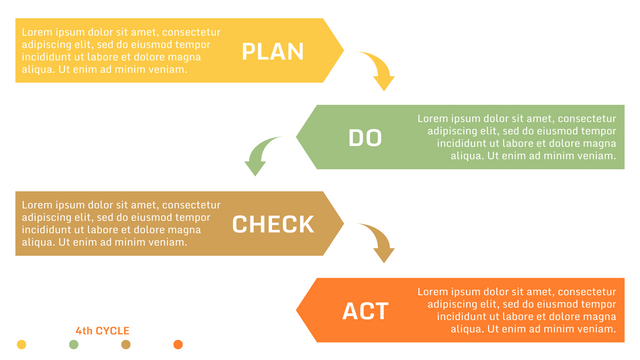

Plan Stage

Identify needs and opportunities

Set your expectations

Determine the basic plan to meet your needs and opportunities

Determine financial and personnel requirements and schedules

Do Stage

Identify responsible and affected persons

Develop procedures and tools to achieve goals and meet plans

Develop and provide training related to the program and personnel

Follow procedures, processes and tools

Check Stage

Evaluate your performance

Determine if you are meeting our goals and targets

Are things going as planned and expected

Find any "root cause" and determine corrective actions

Action Phase

Determine what needs to be changed (if any)

Determine specific adjustments

Decide if we stick to your current plan or if you want to do something else