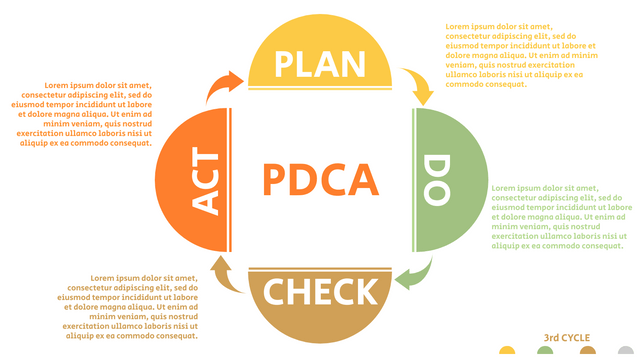

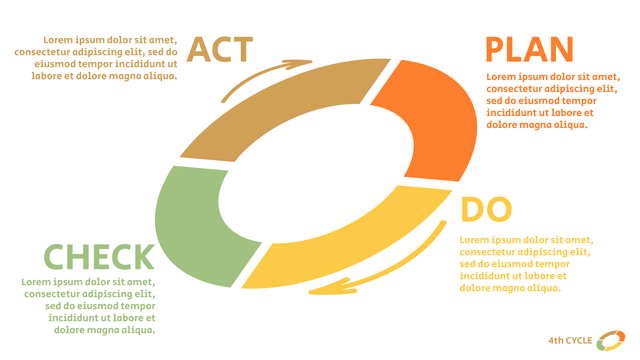

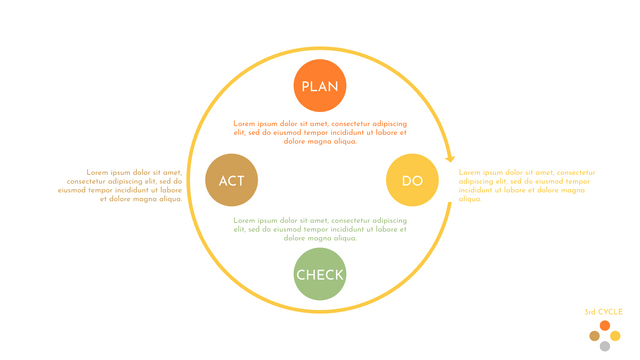

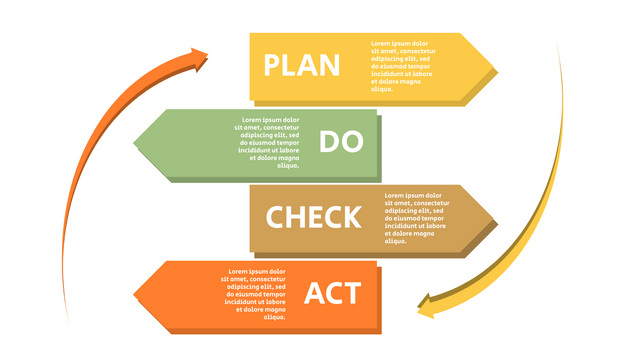

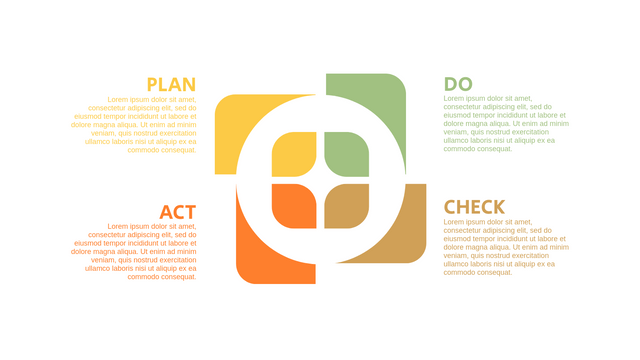

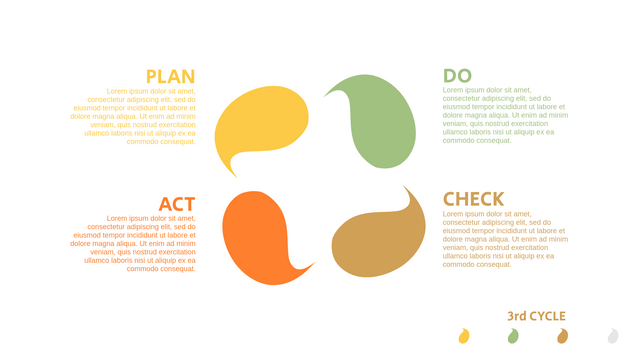

The PDCA cycle describes an iterative process in which ideas are planned, implemented, analyzed and measures are derived. It is particularly suitable for new development and improvement of products and processes. Instead of a complicated method, you can view PDCA as a logical way of thinking: If you want to try something new, you first come up with a concept, try it out, learn from it and derive measures.

Purpose of PDCA Cycle

In PDCA, we should first tested our ideas in a small scale instead of being rolled out directly on a large scale. PDCA cycle is suitable for a wide variety of domains for different industries, which includes:

Improvement of any product or process

Support with the introduction of Total Quality Management (TQM) or Six Sigma projects

Trying out various possible solutions before they are rolled out across the board

Development of new products

Introduction of new company processes

Improvement of supplier management

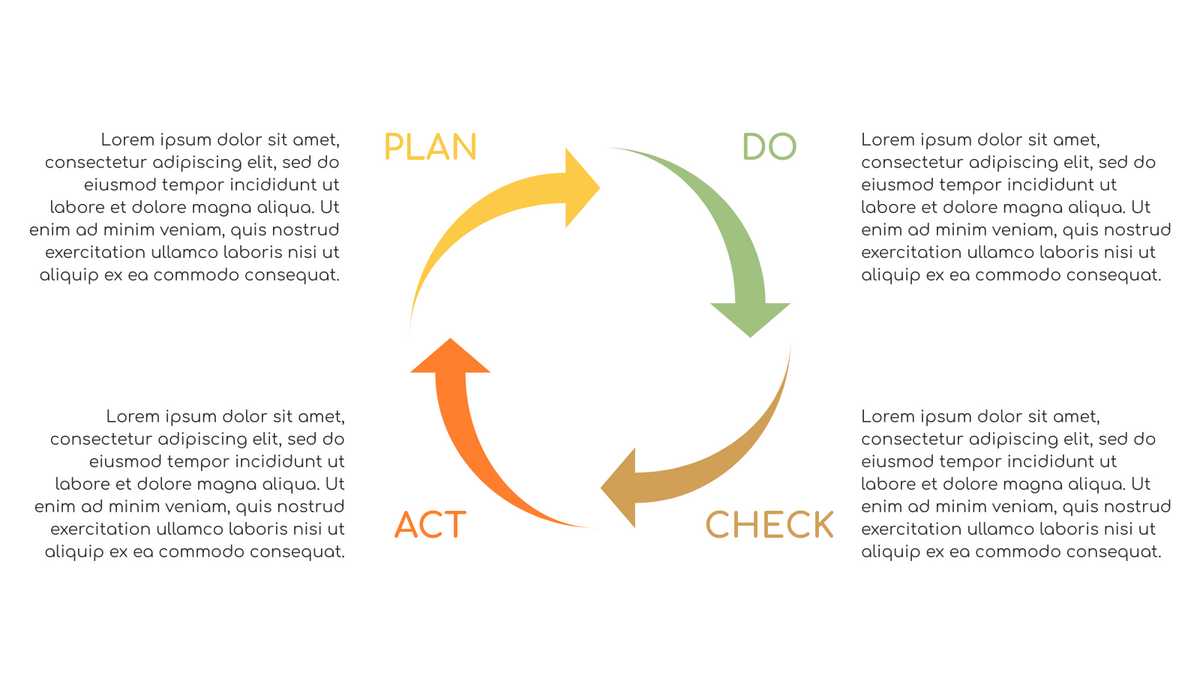

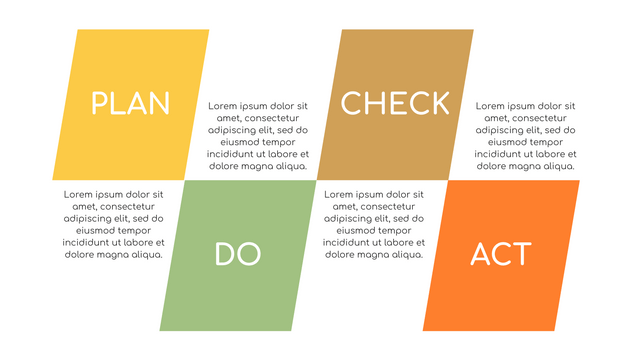

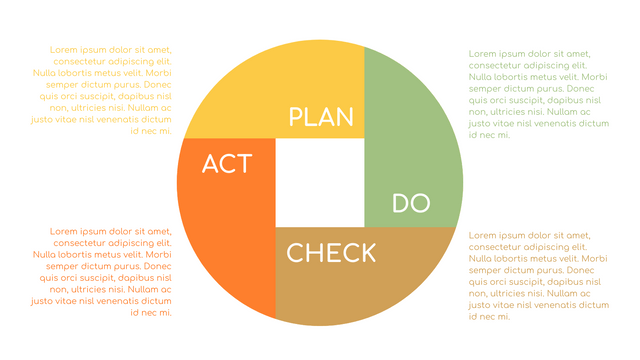

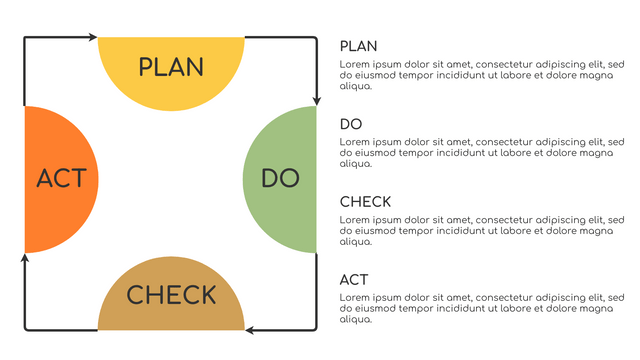

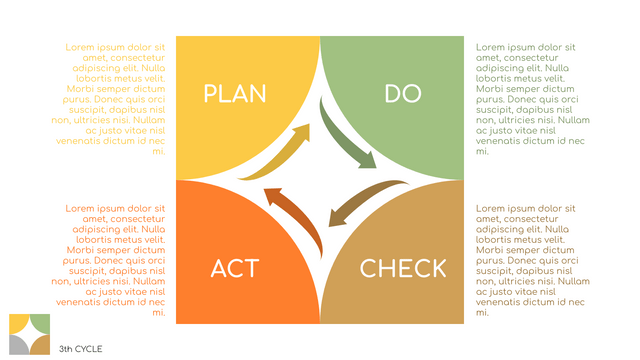

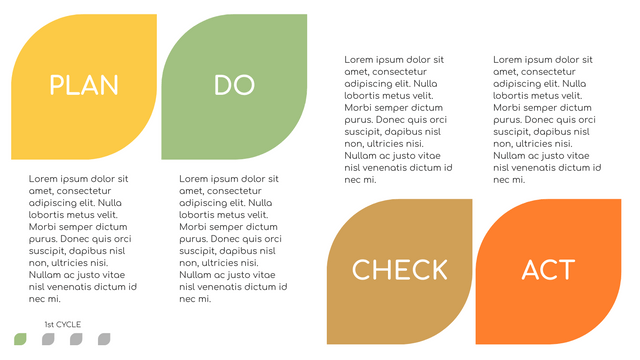

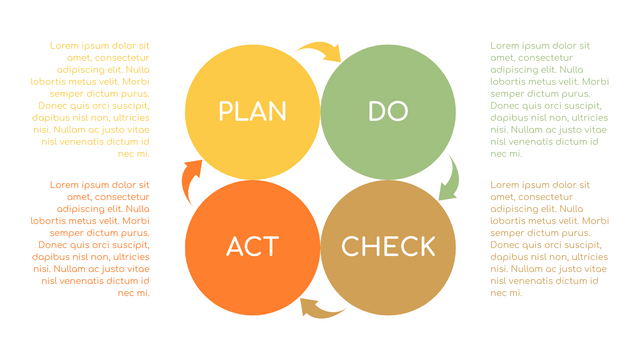

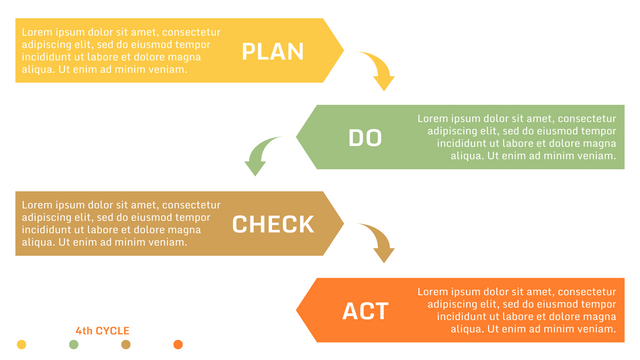

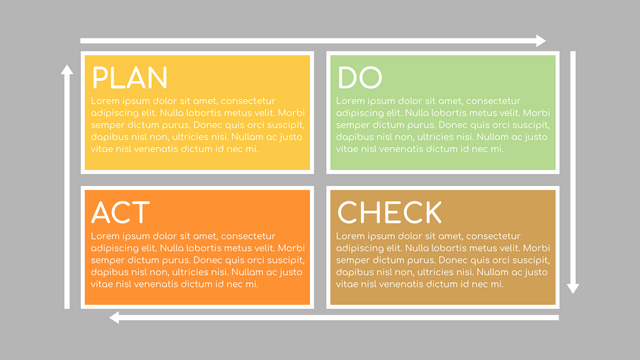

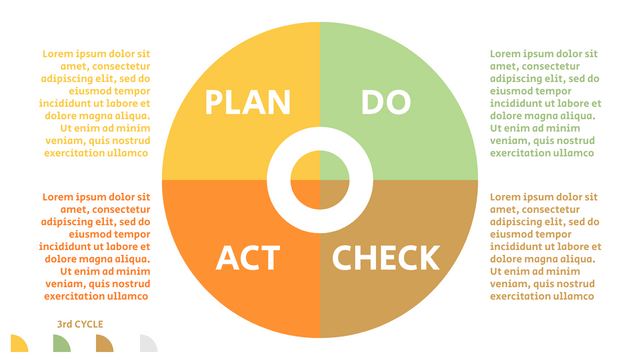

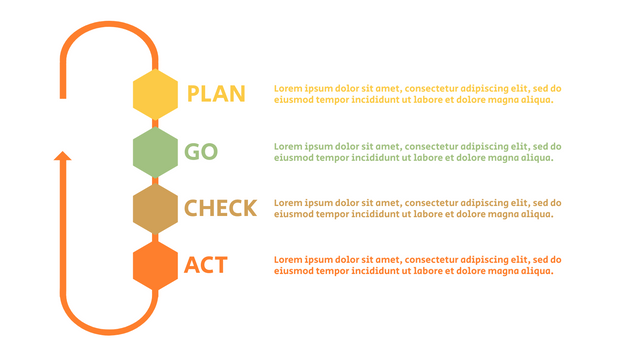

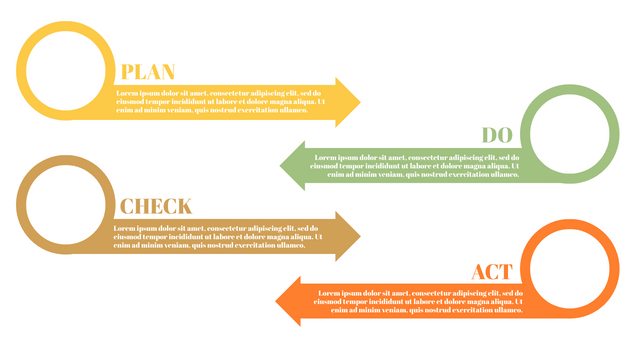

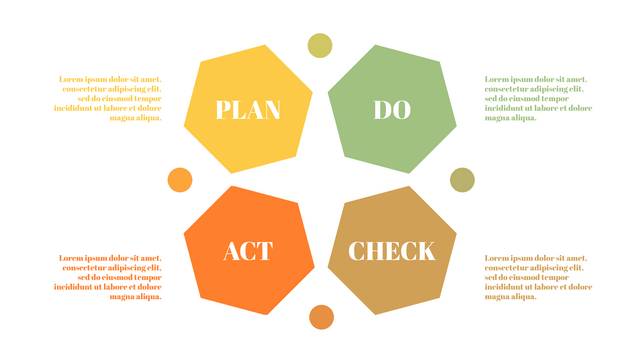

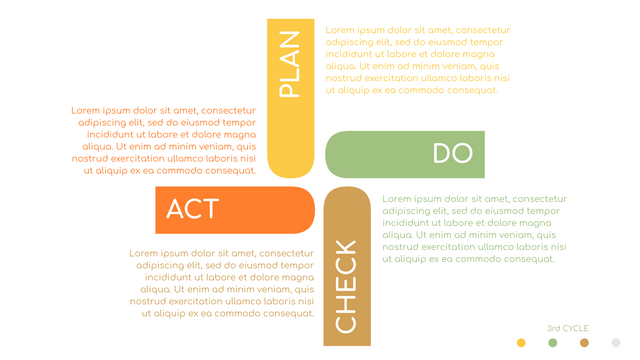

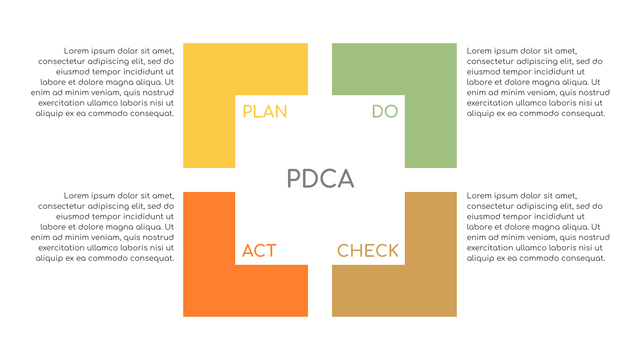

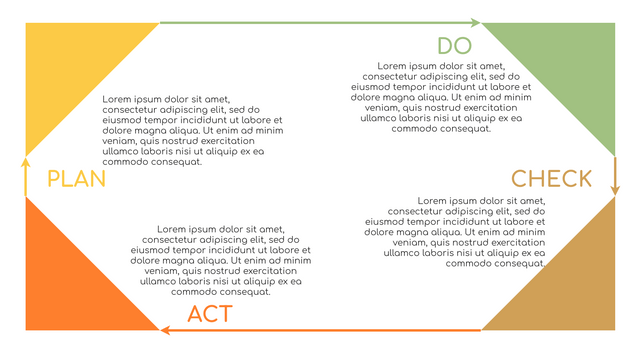

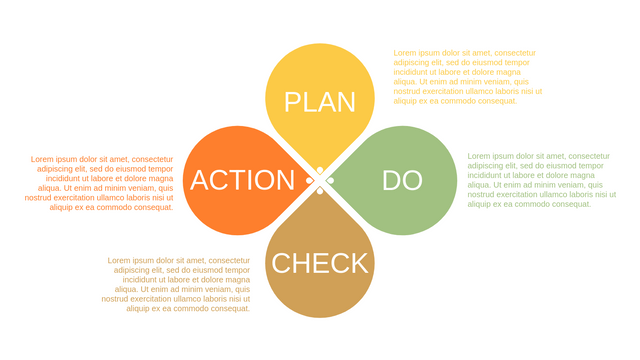

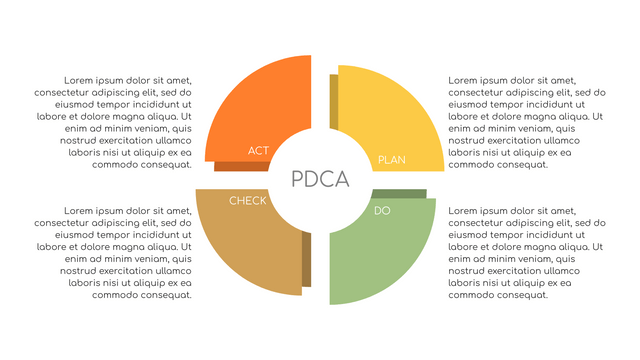

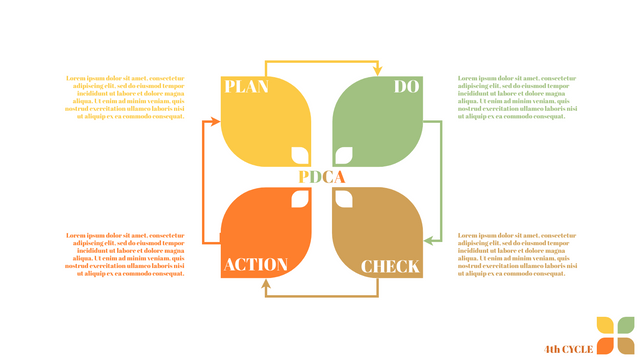

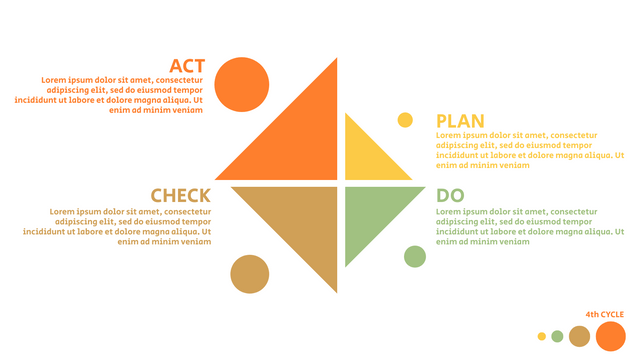

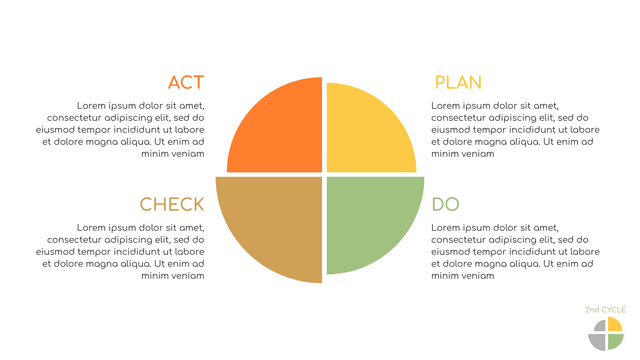

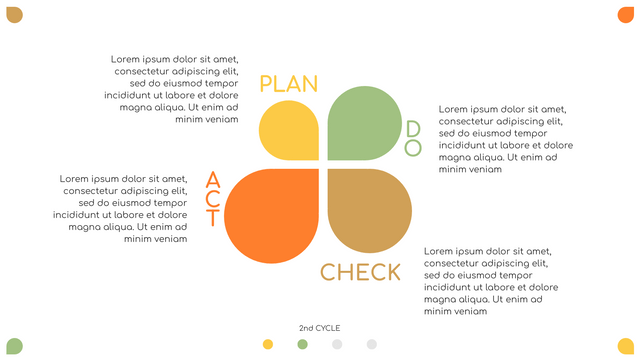

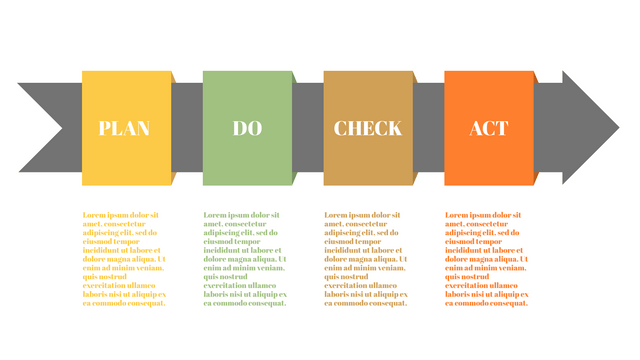

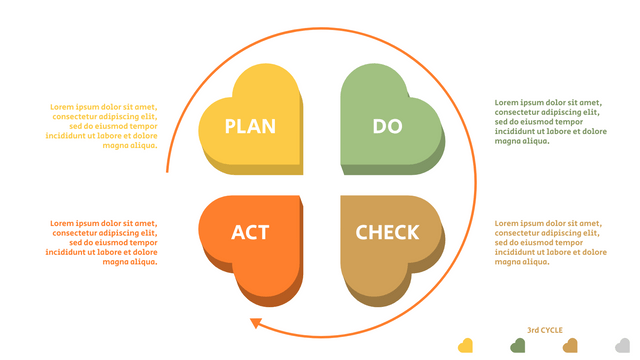

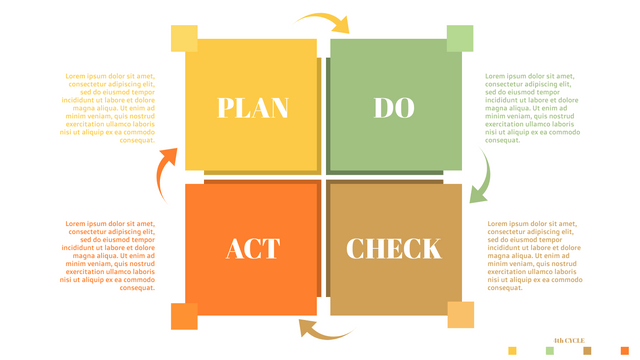

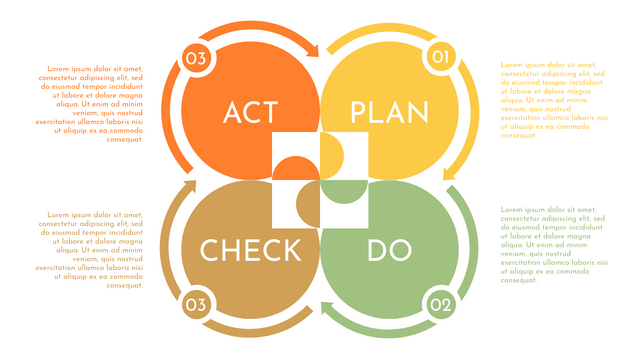

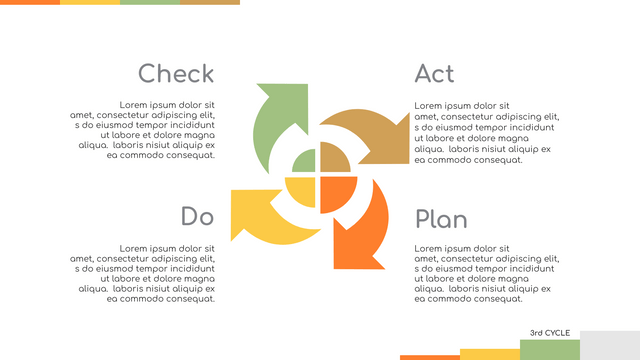

P (Plan) - This stage is to find out the user's requirements for product quality through market surveys, user visits, national plan instructions, etc., and determine the quality policy, quality goals, and quality plans.

D (Do) - This stage is to implement the content specified in the P stage, such as product design, trial production, and testing according to quality standards, including personnel training before the implementation of the plan.

C (Check) - This stage is mainly to check for the plan during and after the execution, and whether it meets the expected results of the plan.

A (Action) - It is mainly based on the inspection results to take corresponding measures and formulate improvement action for the next cycle.

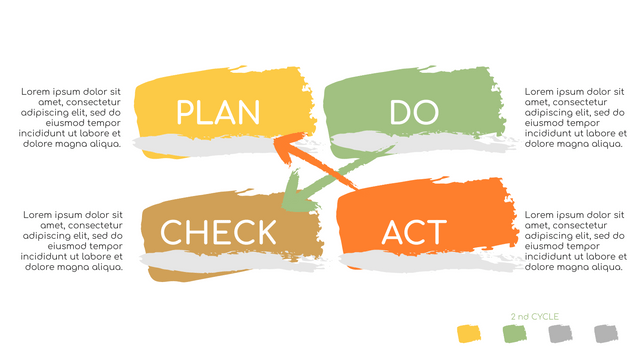

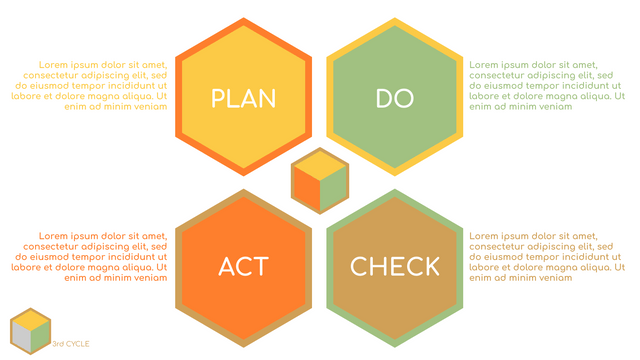

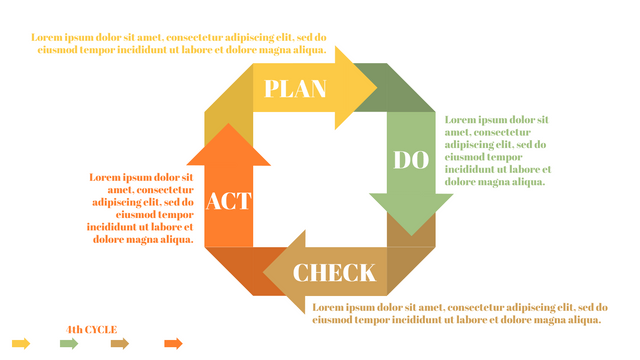

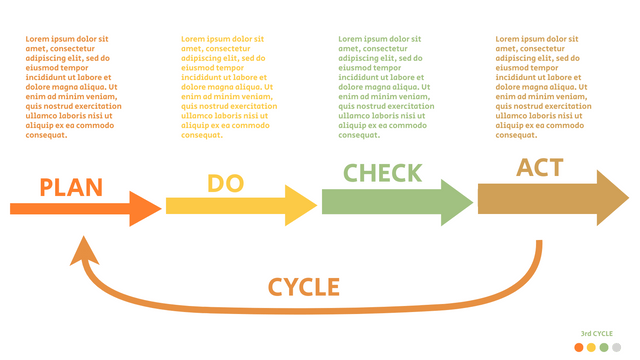

The above four processes do not end after running once, but are carried out over and over again for continuous improvement. When one cycle is over, some problems are solved, and the unresolved problems enter the next cycle, which rises step by step.

The PDCA cycle is actually a logical work procedure for effectively performing any work. In quality management, some people call it the basic method of quality management.