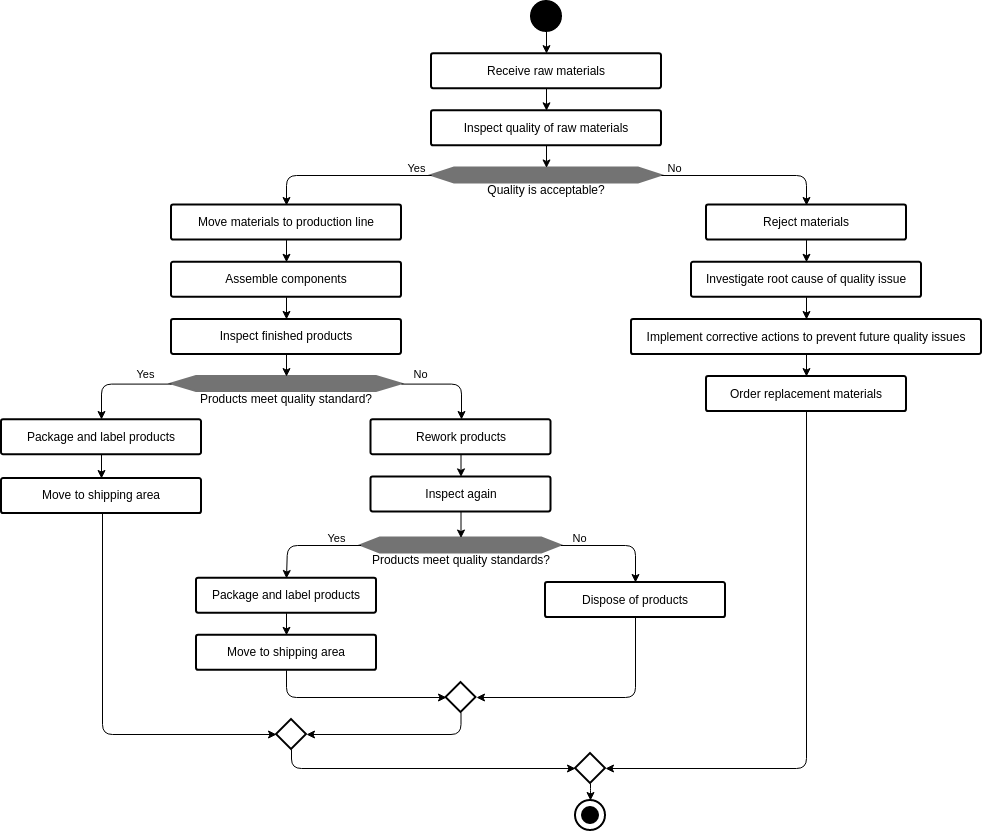

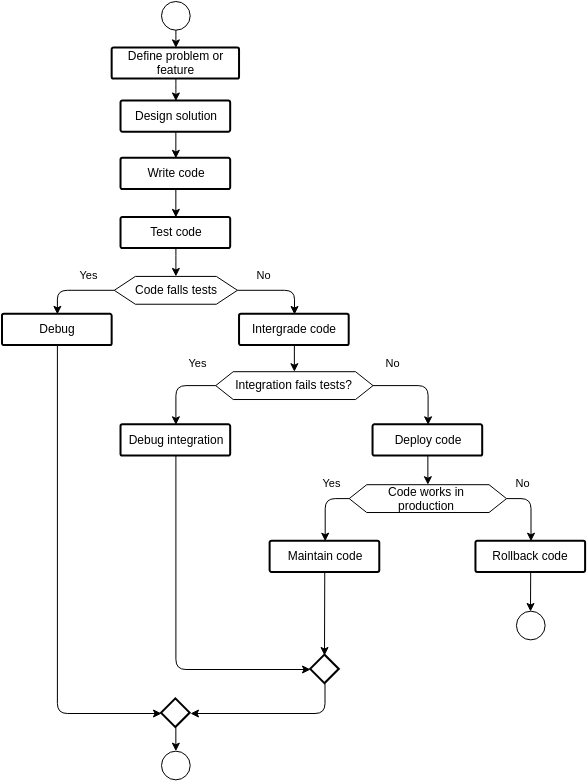

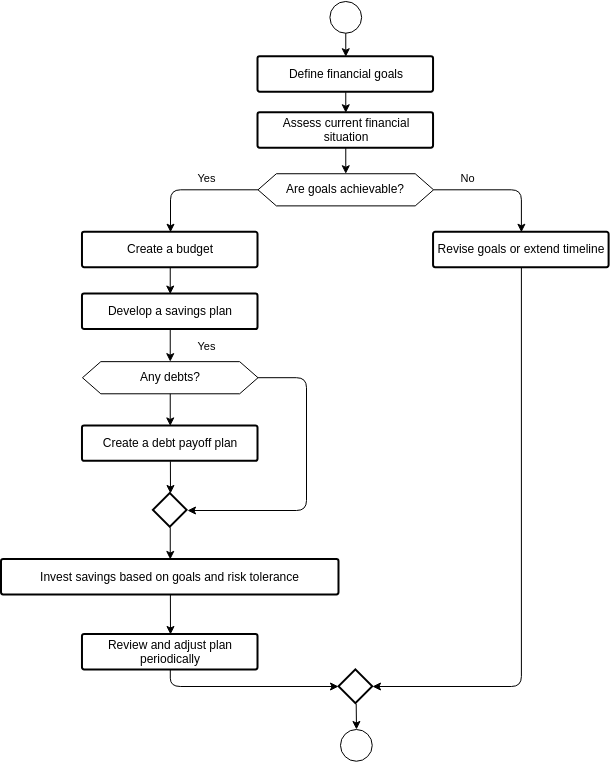

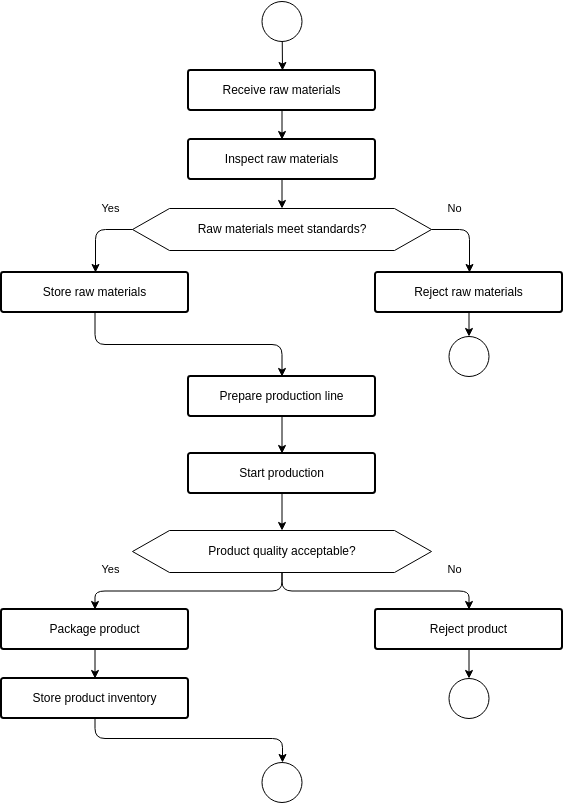

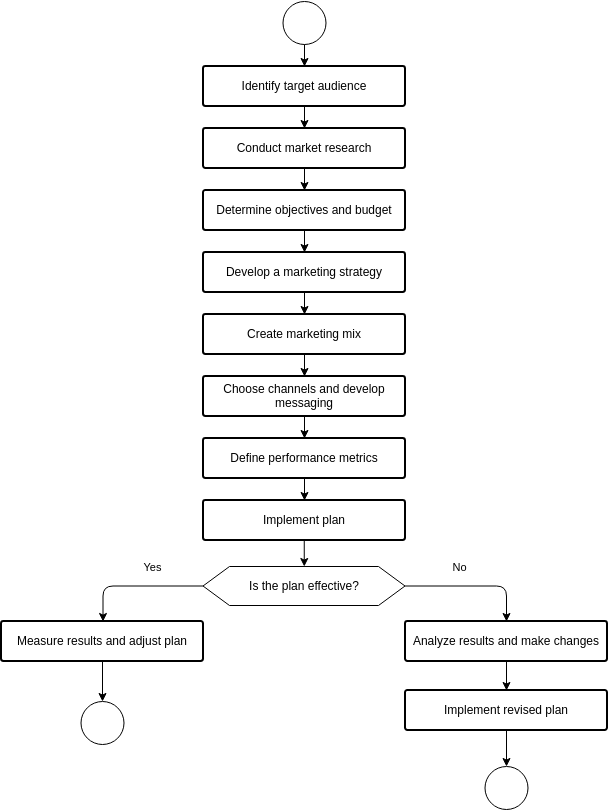

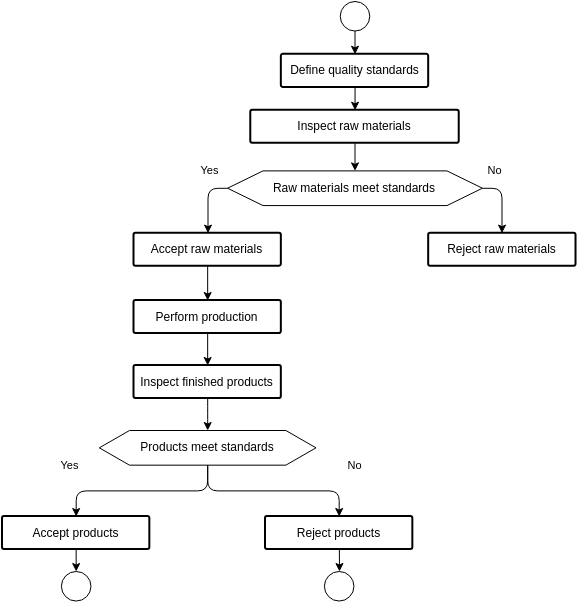

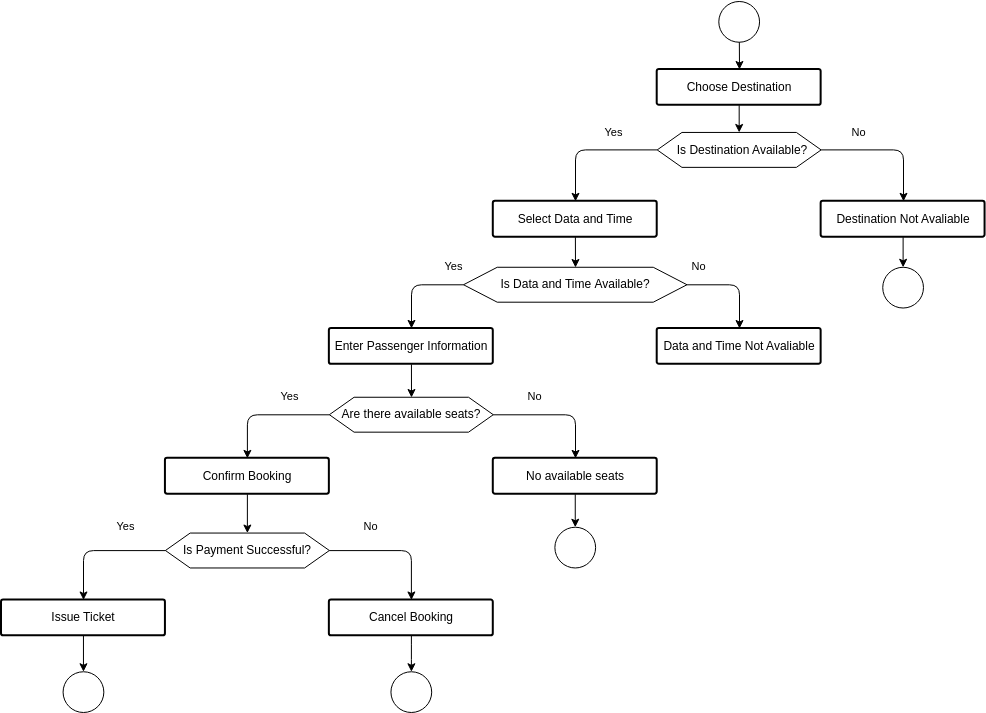

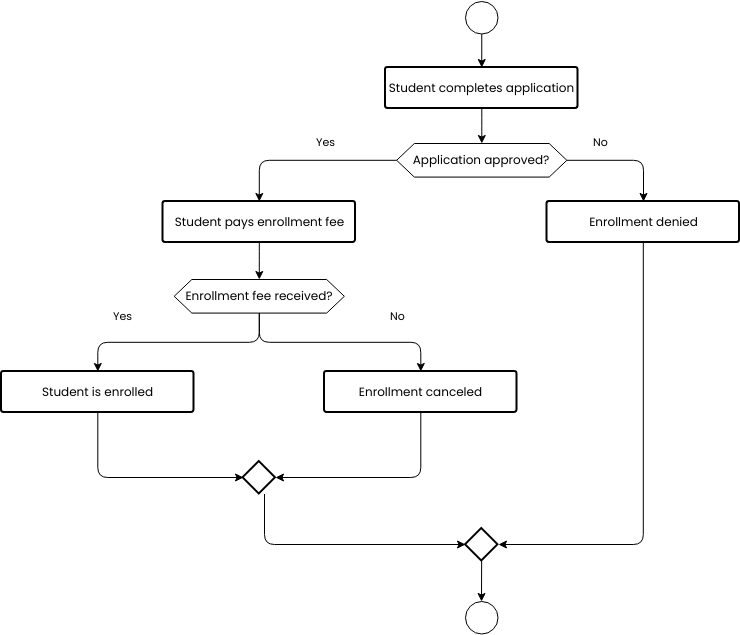

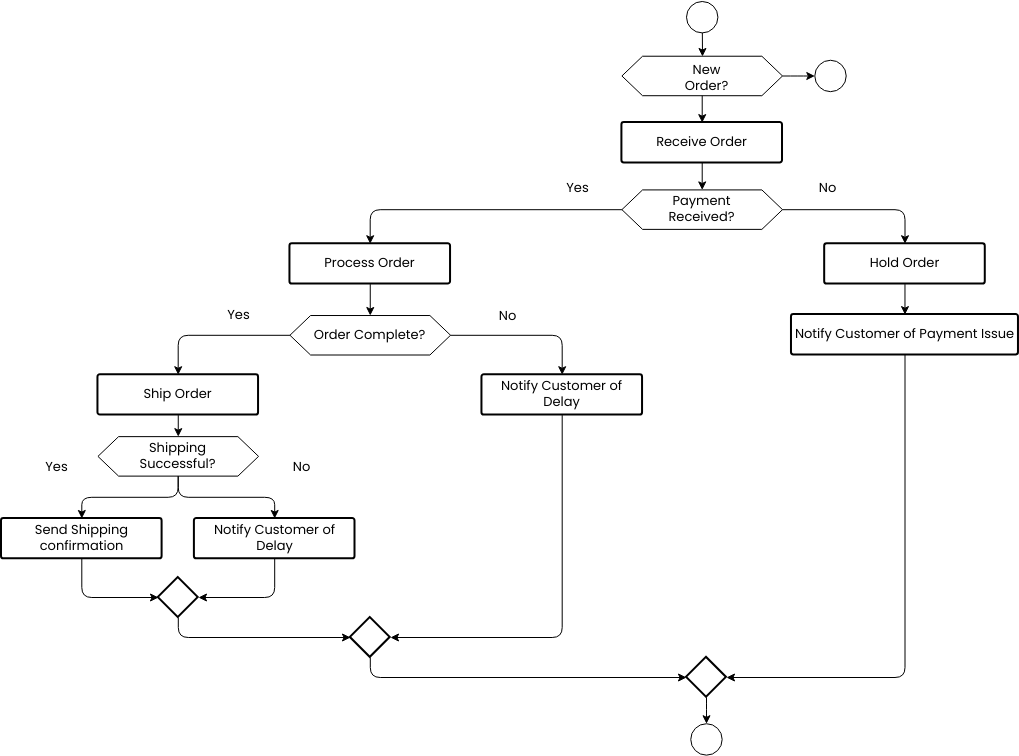

The Improved Process Flowchart outlines the steps involved in the production of a product, starting from the receipt of raw materials to the shipping of finished products. The first step in the process is to receive raw materials. This step involves receiving the raw materials from suppliers and verifying that the materials received match the order placed. Any discrepancies are reported to the supplier and the materials are inspected for quality.

The next step is to move the raw materials to the production line. This step involves transporting the raw materials to the production area and ensuring that they are stored in the correct location. Once the materials are in the production area, the components are assembled as per the production plan. This step involves following the production plan to assemble the components into finished products.

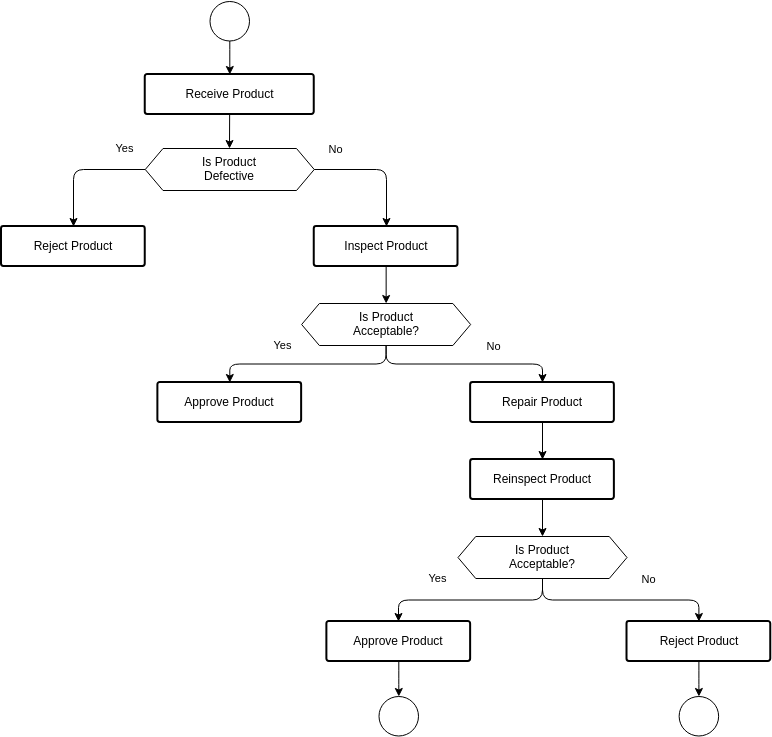

The assembled products are then inspected for quality. This step involves verifying that the components have been assembled correctly and that the finished products meet the required quality standards. If any defects are found, the products are reworked to correct the issue. Once the defects have been corrected, the finished products are inspected again to ensure that they meet the required quality standards.

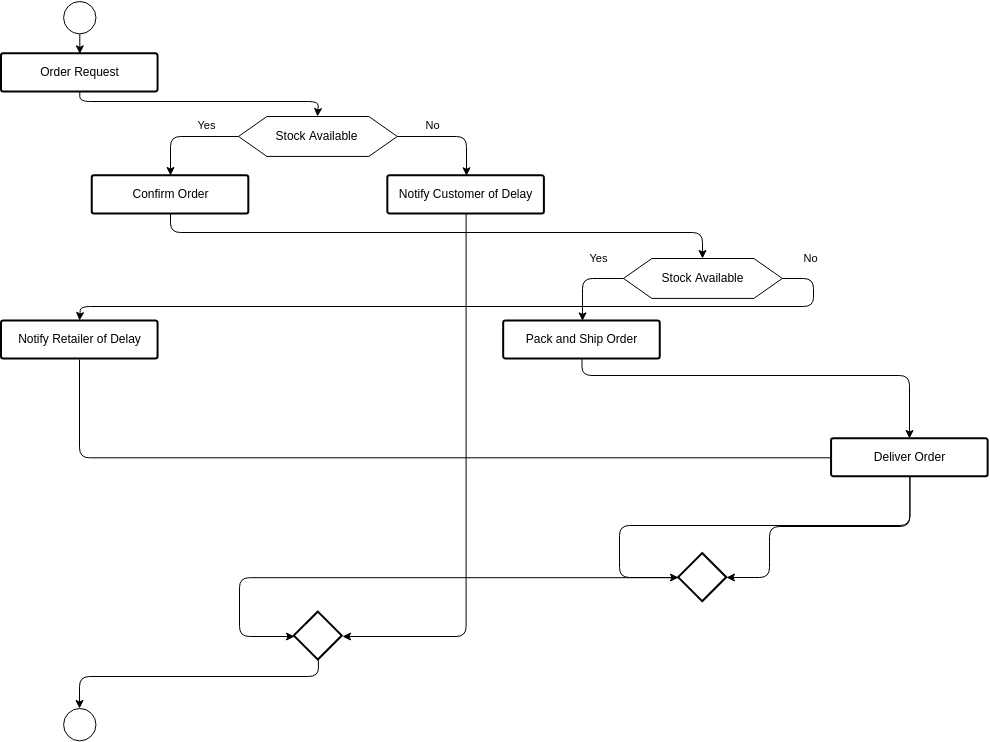

After the products have been inspected and approved, they are packaged and labeled. This step involves packaging the finished products in the appropriate packaging material and labeling them according to the product specifications. Once the products have been packaged and labeled, they are moved to the shipping area. This step involves transporting the finished products to the shipping area where they are prepared for shipment to customers.

Importance of creating improved process flowchart

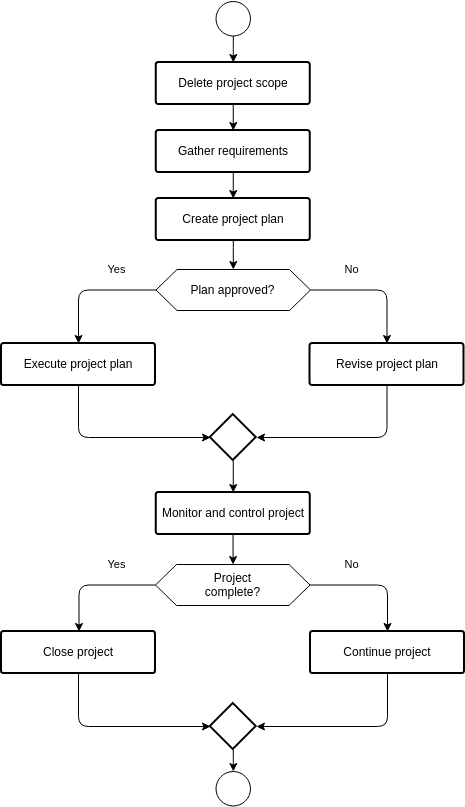

Creating an Improved Process Flowchart is important for a company for several reasons. Firstly, it helps to standardize the process of production. By following a standardized process, the production team can ensure that products are consistently produced to the required quality standards. This helps to reduce the likelihood of errors or defects in the products, which can lead to customer complaints and product recalls. The flowchart can also serve as a reference tool for staff members, allowing them to quickly access information about the correct procedures to follow. This helps to reduce the learning curve for new staff members and ensures that everyone is following the same process.

Secondly, the flowchart can help to improve the efficiency of the production process. By clearly outlining the steps involved in the production process, the flowchart can help to identify any bottlenecks or inefficiencies in the process. This information can then be used to make improvements to the process, such as automating certain steps or reallocating staff resources. Streamlining the production process can help to reduce the time it takes to produce products, which can help to improve delivery times to customers and reduce costs.

Do you need templates for flowchart design? Right away, go to Visual Paradigm Online to look at some of your favorite customizable templates.