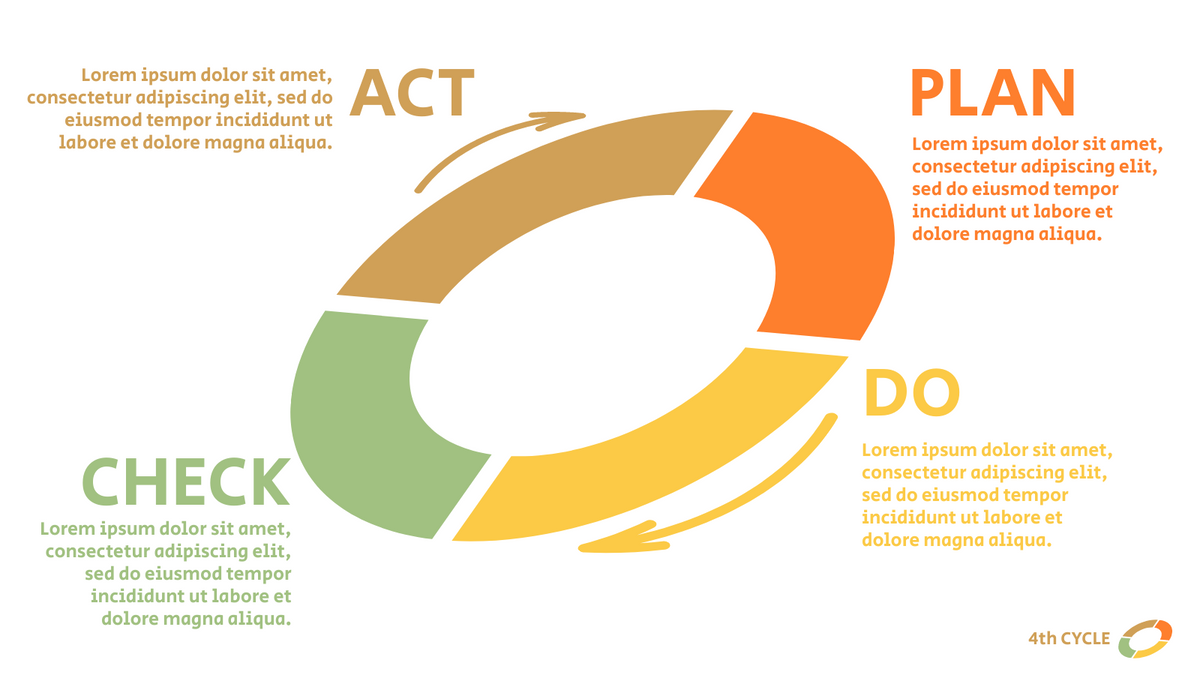

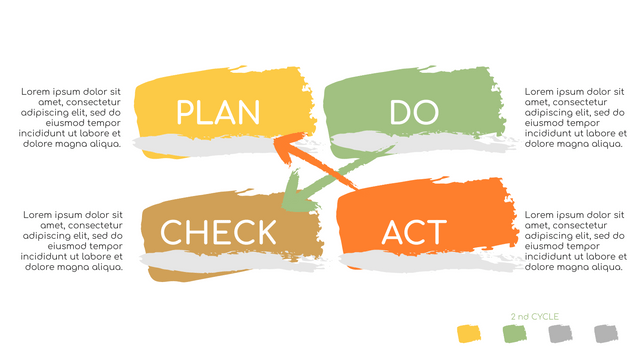

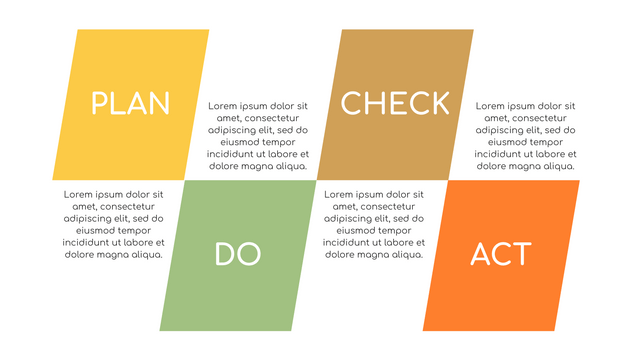

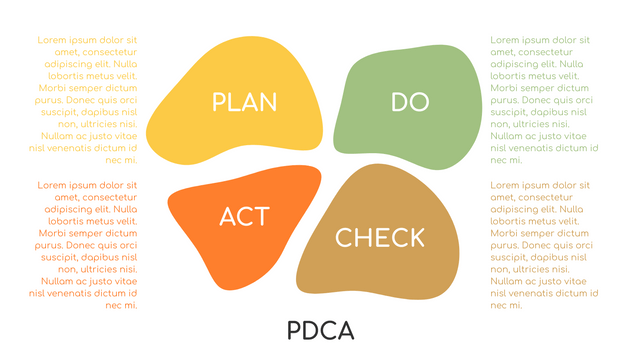

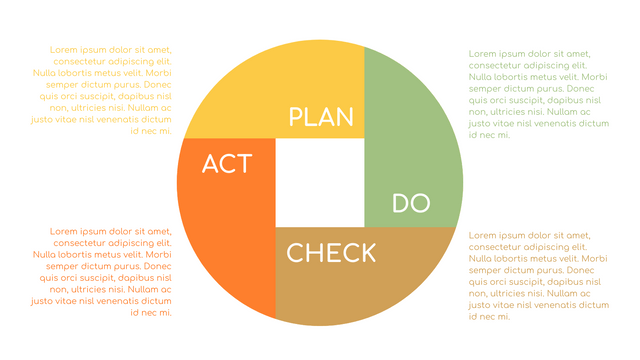

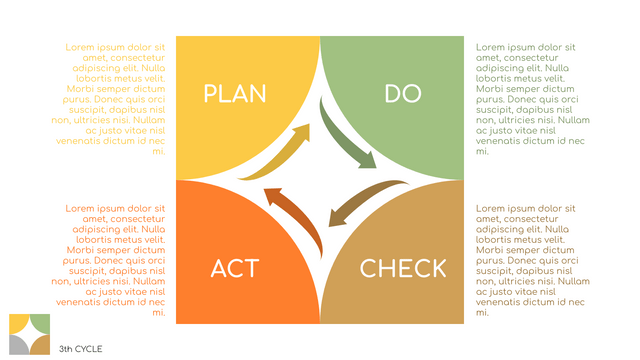

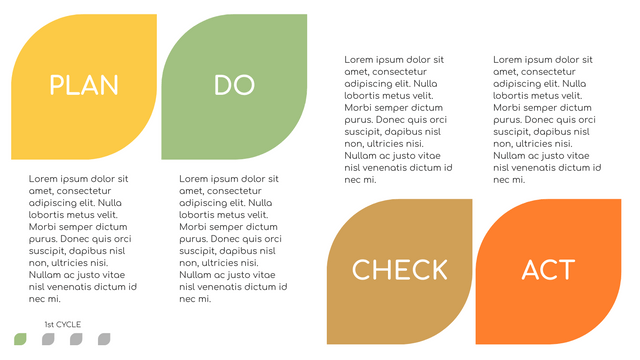

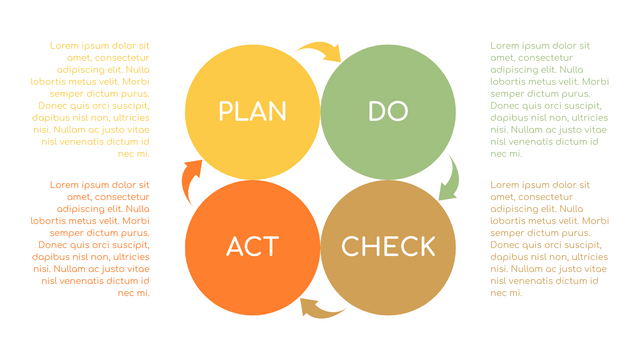

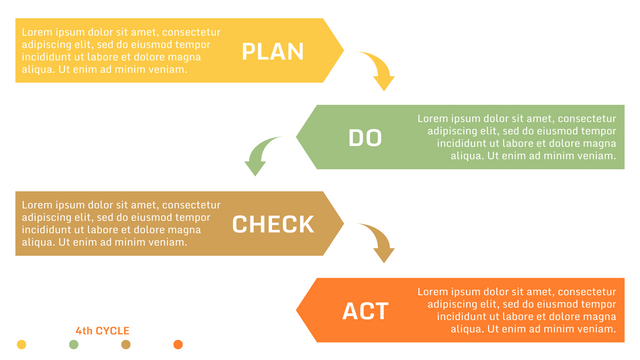

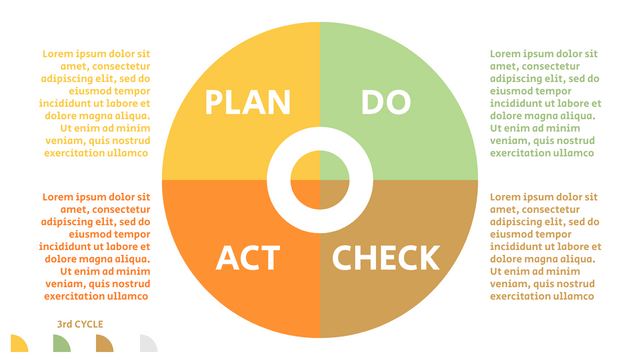

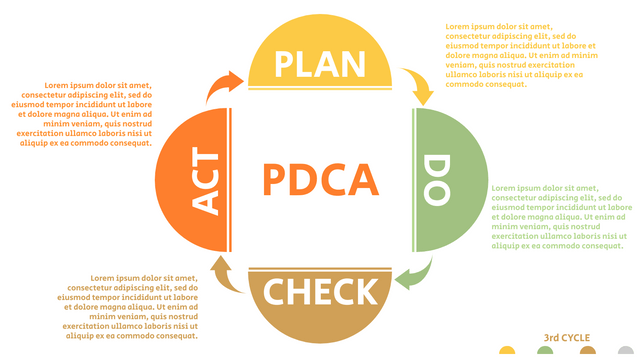

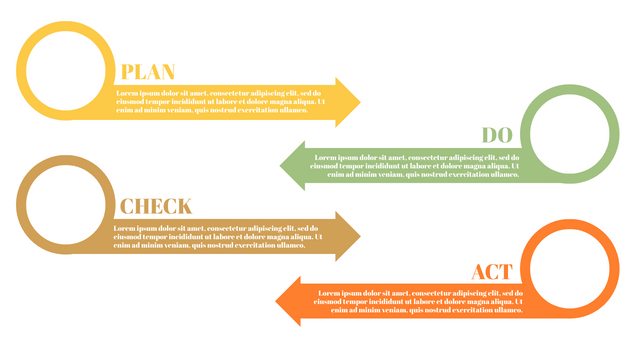

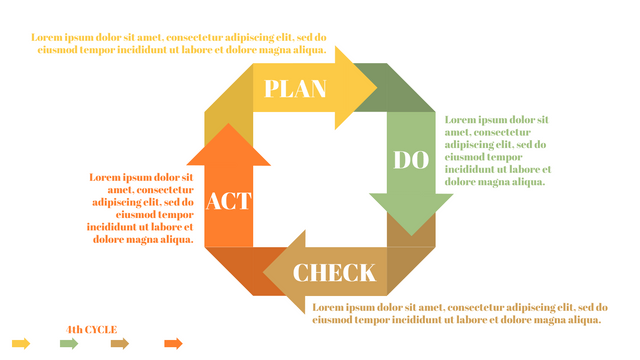

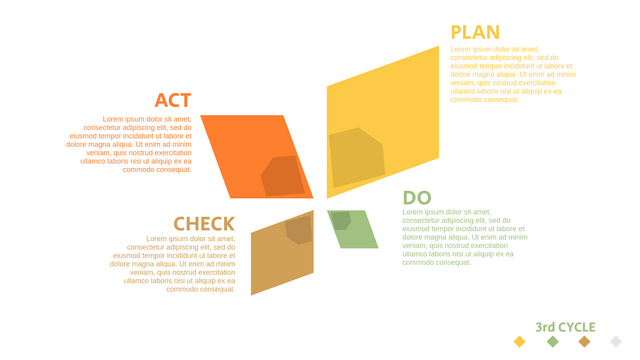

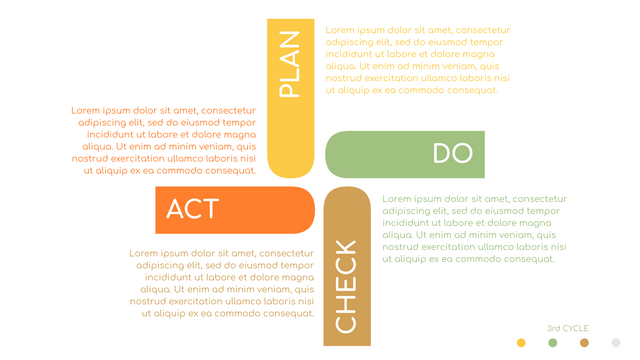

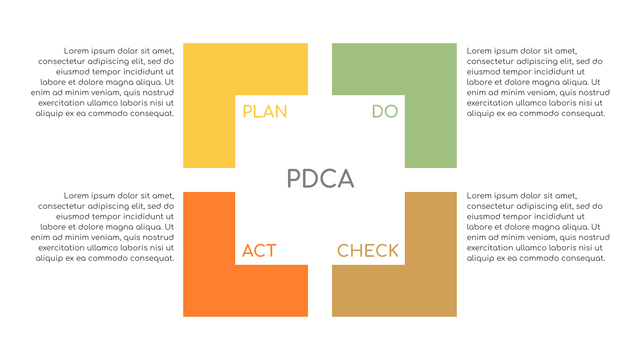

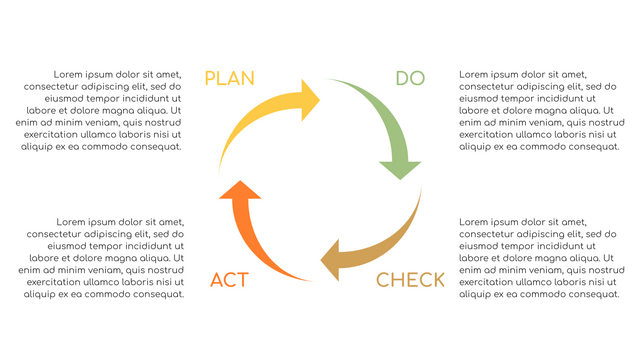

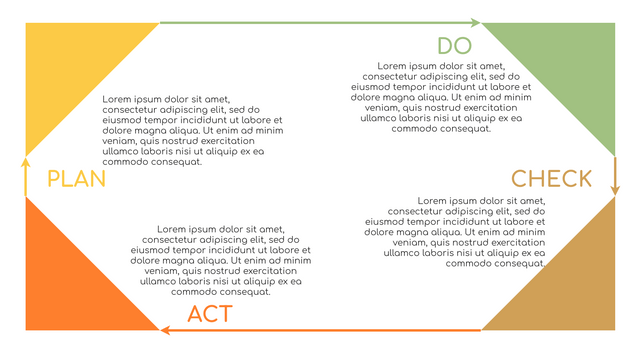

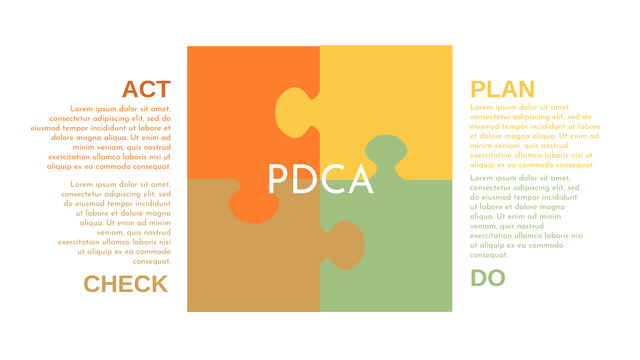

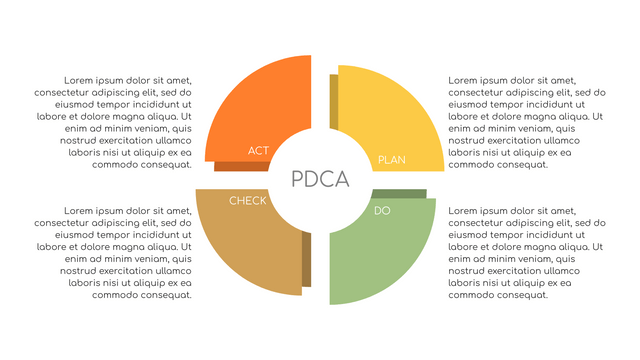

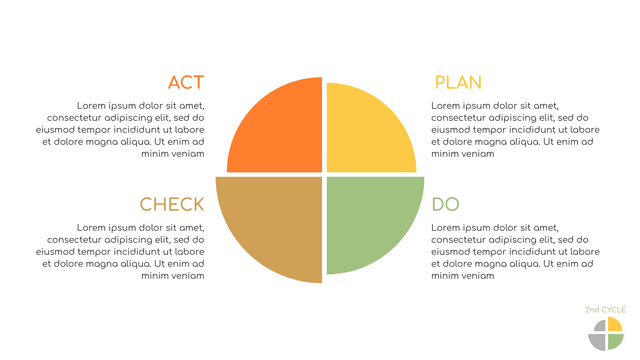

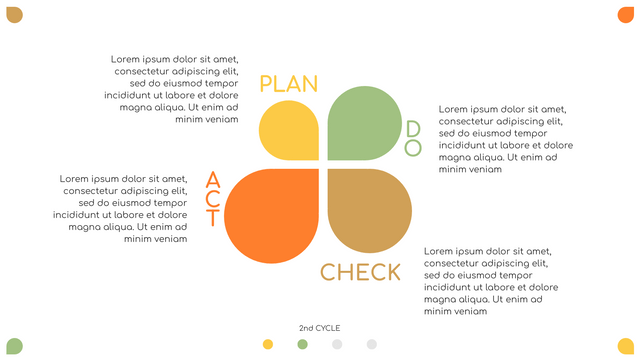

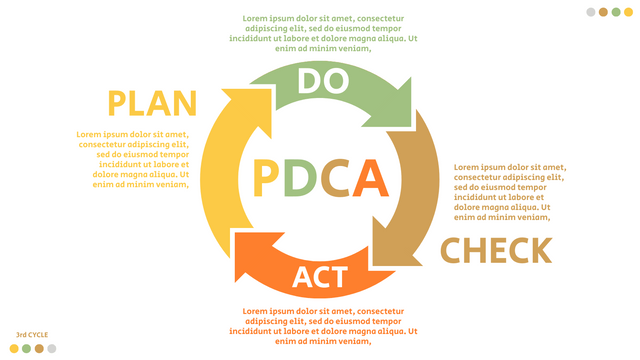

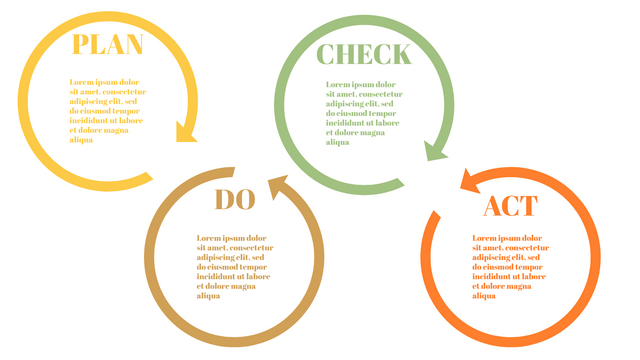

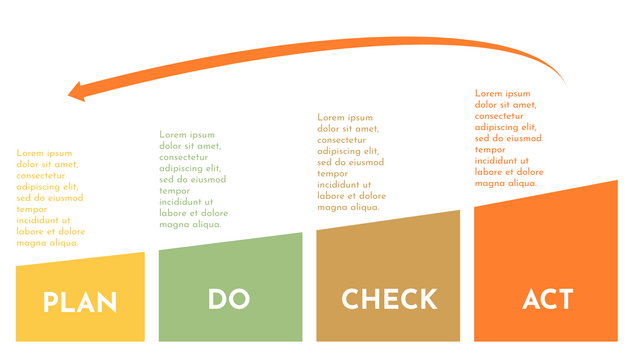

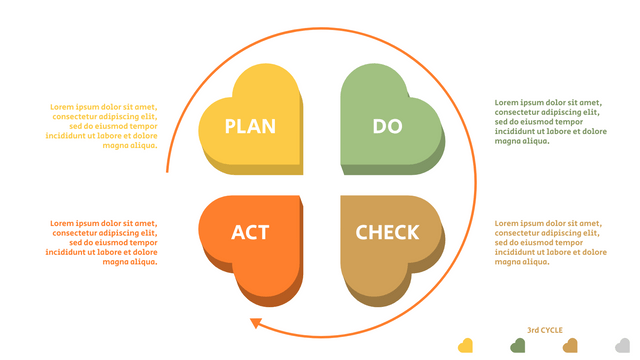

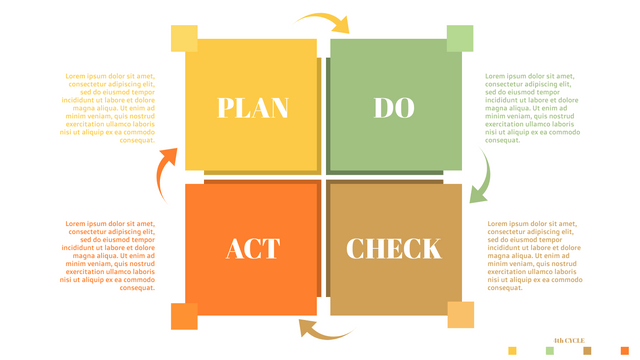

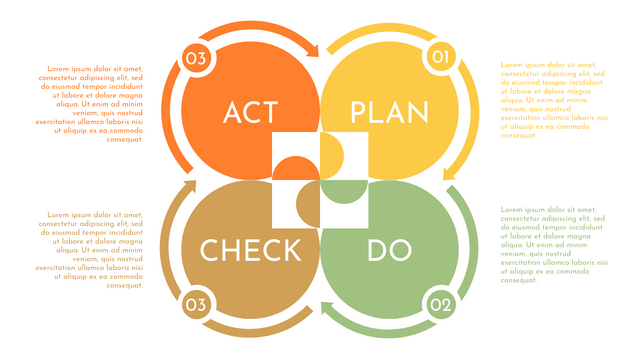

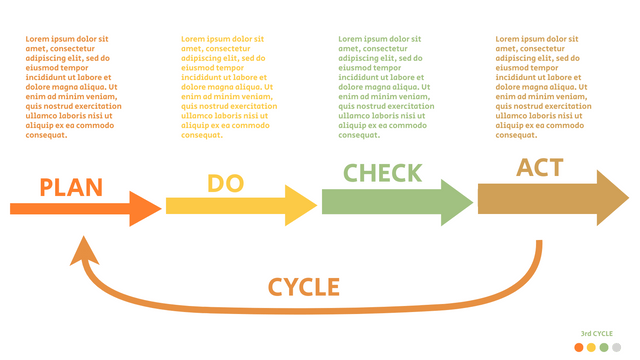

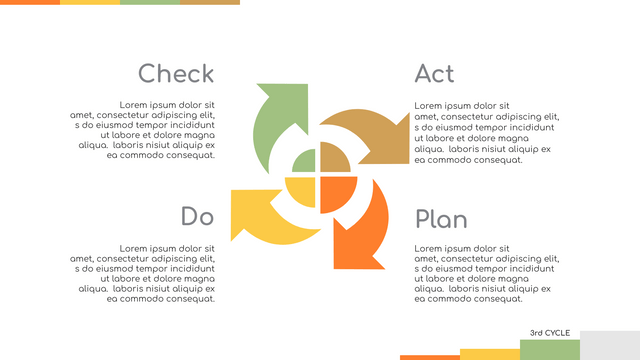

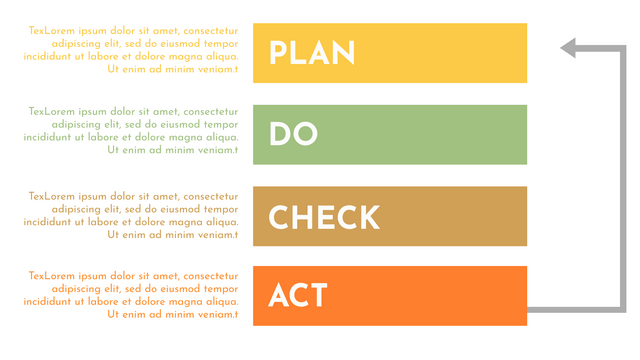

PDCA is a common way to implement a project or any other work. That is, before you can do anything, you must have a thorough plan (plan) under which to perform, check that the task has been completed as planned (check), and take corrective or improvement action if necessary (action). Then move on to the next cycle of PDCA, continuous improvement iteratively and incrementally.

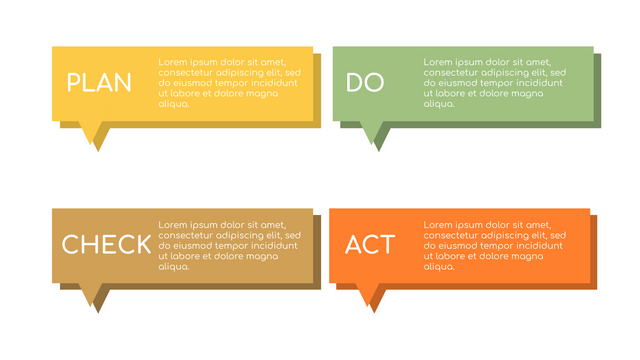

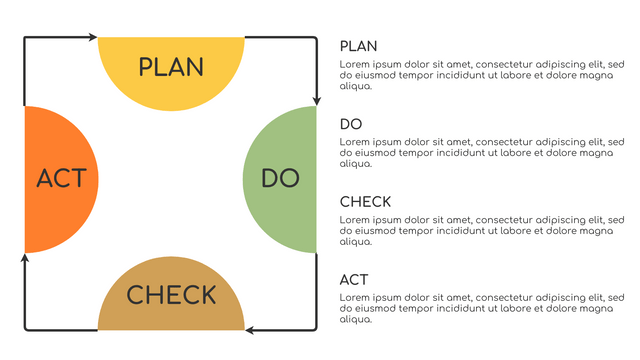

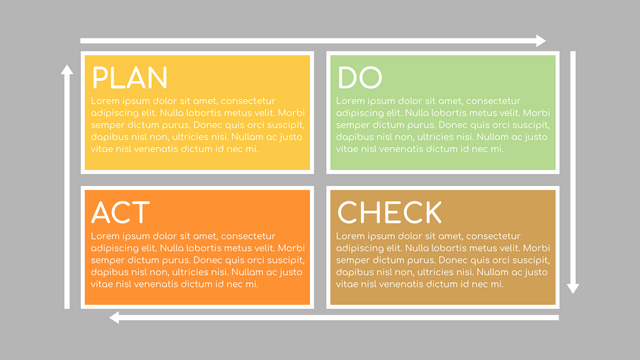

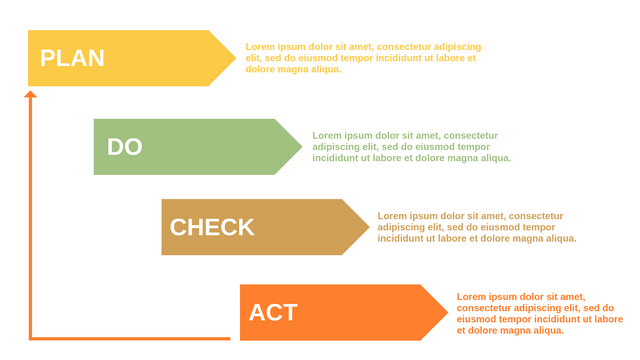

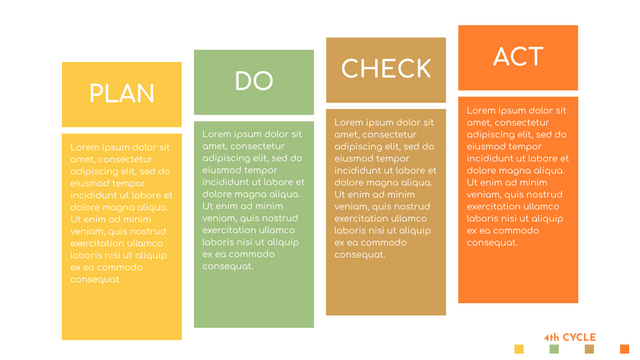

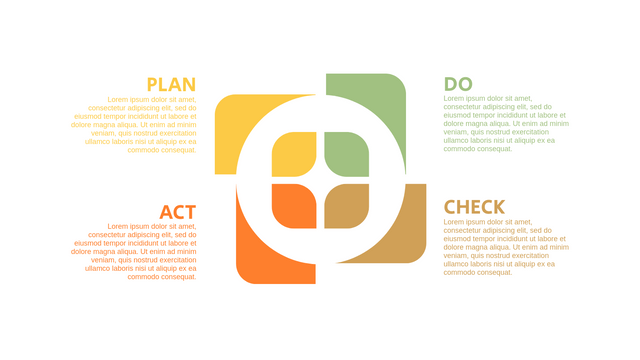

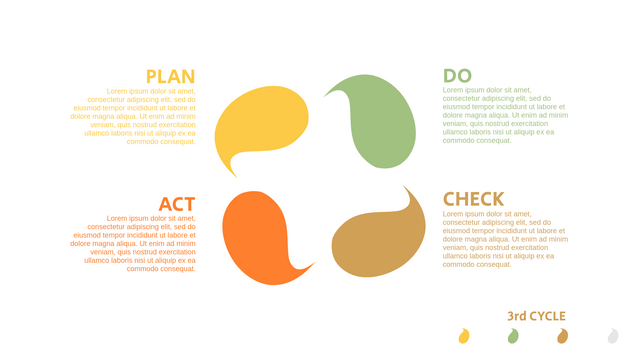

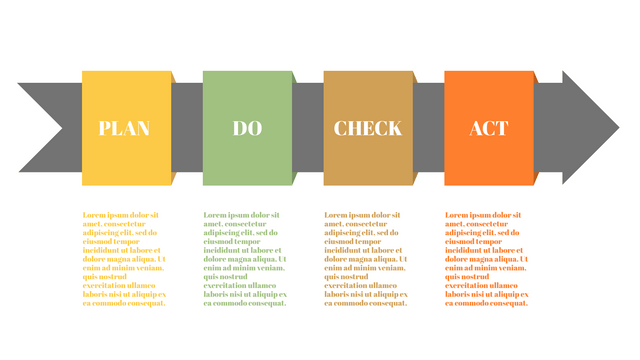

The PDCA model can be briefly described as follows:

Plan (Planning): According to customer requirements and organizational policy, establish the necessary goals and processes for providing results.

Do (implementation): implementation process.

Check (Inspection): Monitor and measure the process and products according to the policies, objectives and product requirements, and report the results.

Act (Disposal): Take measures to continuously improve process performance.

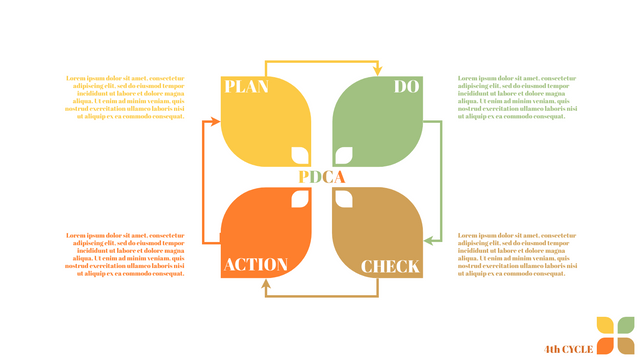

Guideline of the Deming Cycle (or known as Deming Wheel)

Deming's theory reflects the comprehensiveness of quality management, showing that quality management and improvement are not the matter of individual departments, but need the leadership and promotion of top managers to be effective.

The core of Deming's theory can be summarized as 7 guidelines as follows:

The determination and participation of senior management;

Team spirit of teamwork;

Improve quality awareness through education;

Technical training for quality improvement;

Develop standards for measuring quality;

Understanding of the analysis table of quality cost; continuous improvement campaign;

The participation of employees at all levels.