PDCA cycle is also called "Deming cycle". PDCA stands for plan, do, check and adjust. William Edwards Deming is an expert of quality management in America, but he is famous in Japan. With his help, Toyota has achieved great success. Mr. Toyoda said: Deming is the core of our management. Japan even set up Deming award, the highest national award in the field of quality management.

"If Japan can, why can't we?"?

- Deming, documentary NBC broadcast, 1980

Deming believes that high quality does not come from product inspection based on results, but from continuous improvement based on process. Later, the concept was not only used in quality management, but also widely used in the field of enterprise management.

What is PDCA Cycle?

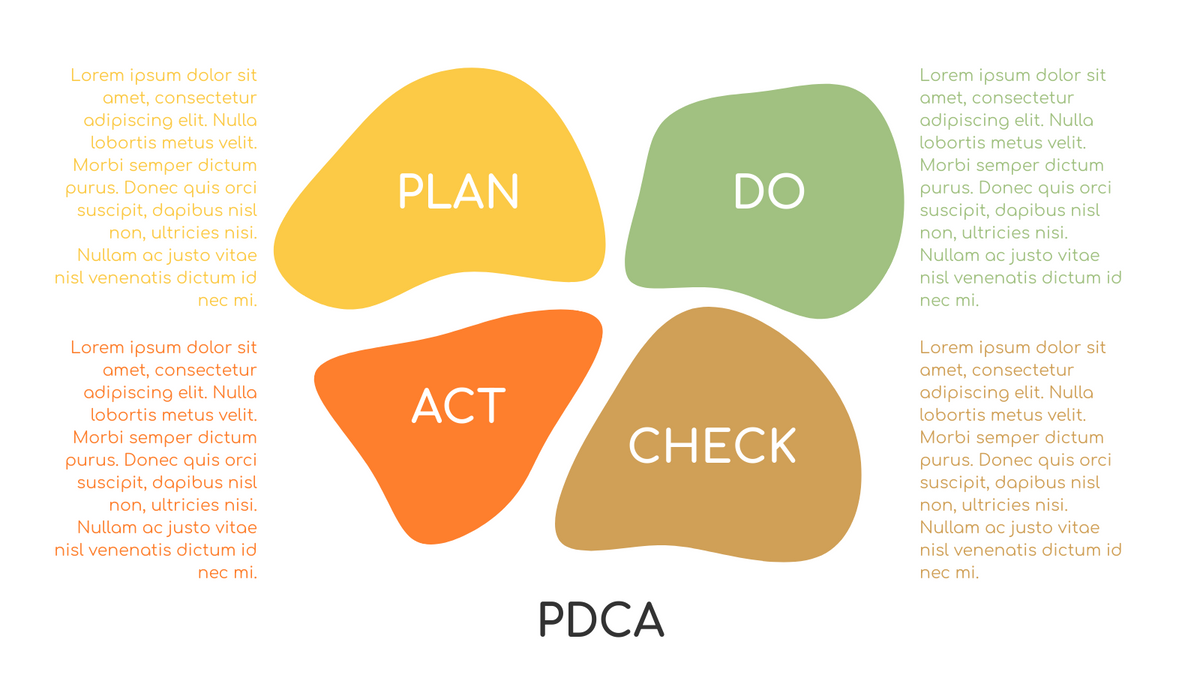

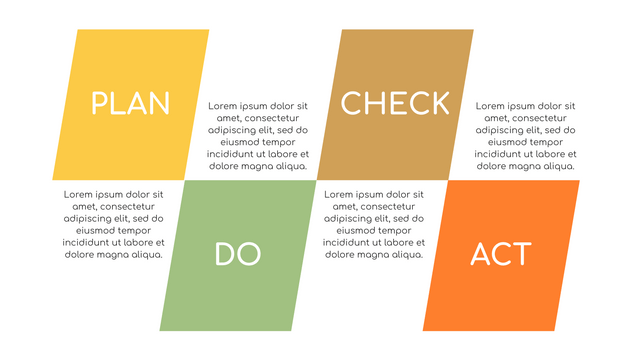

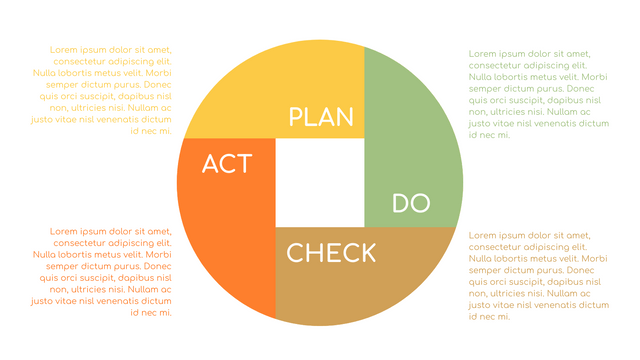

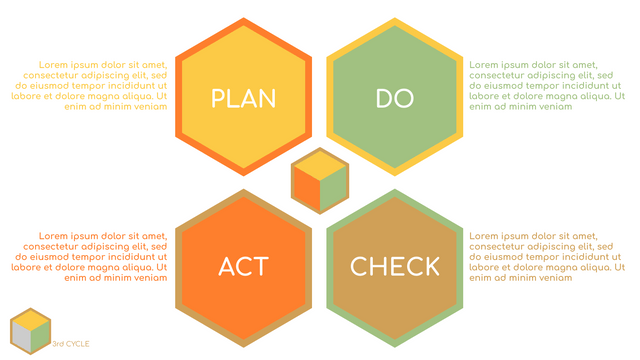

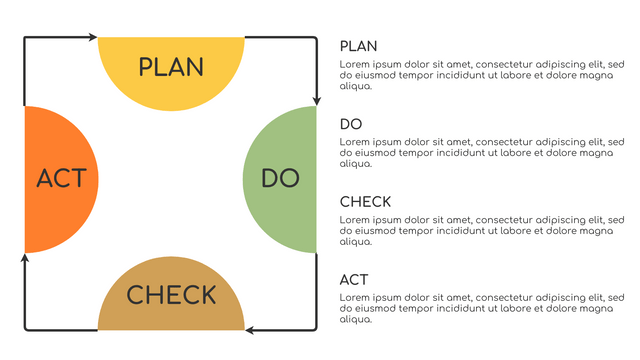

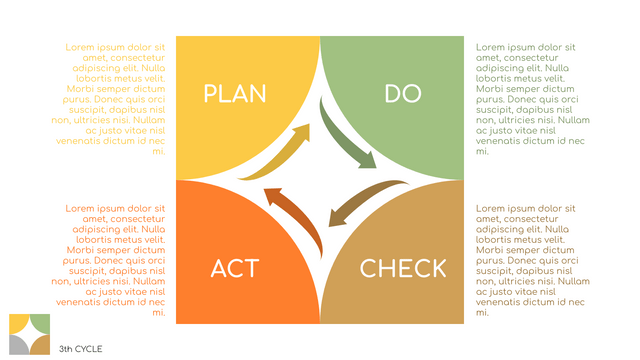

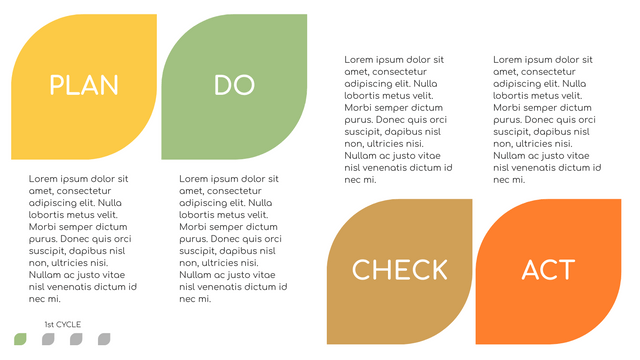

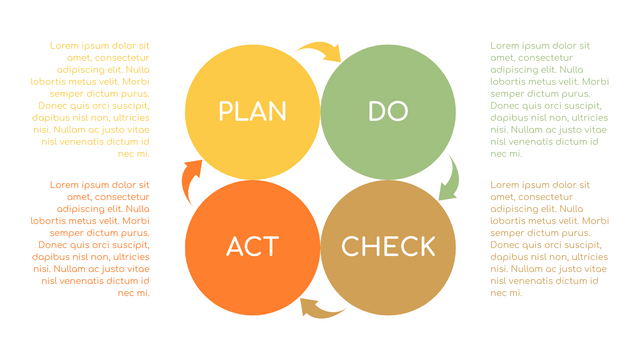

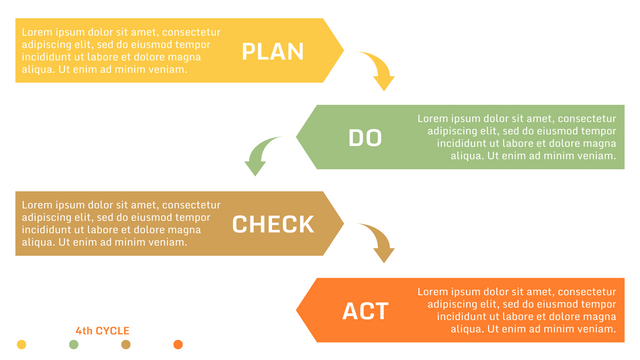

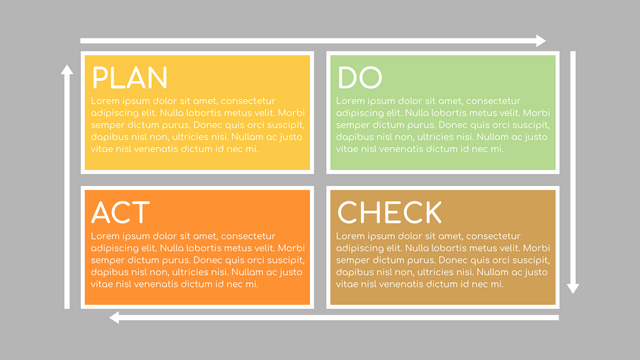

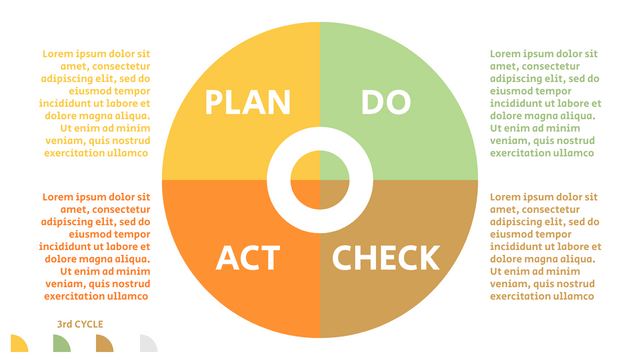

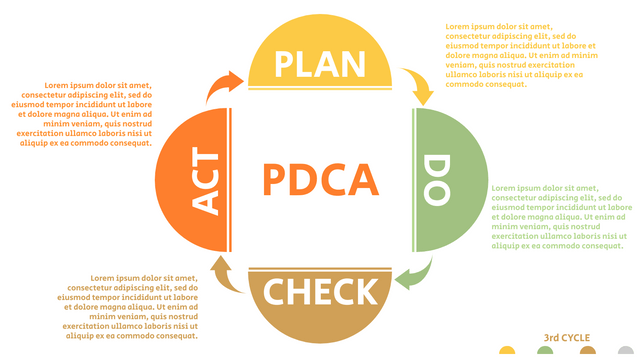

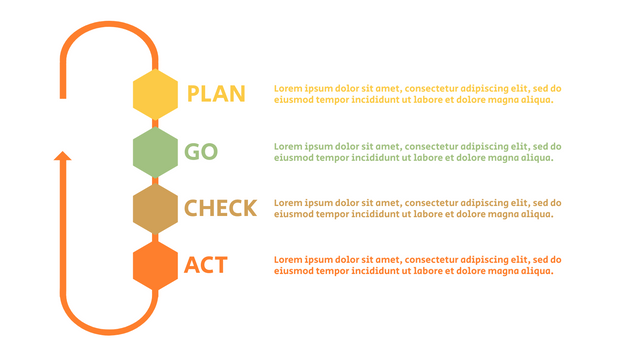

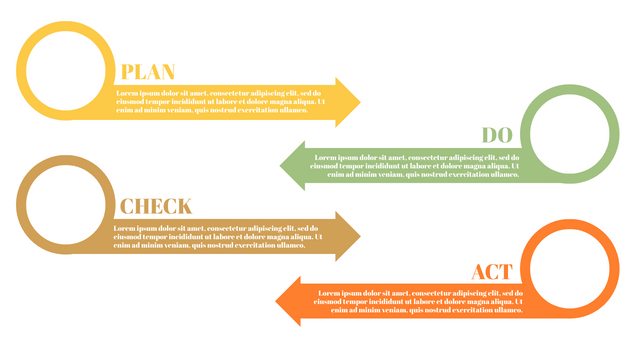

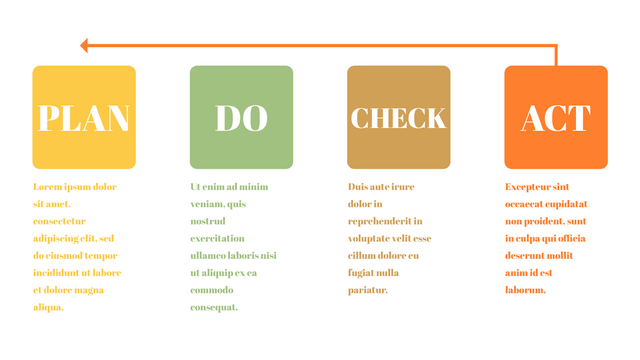

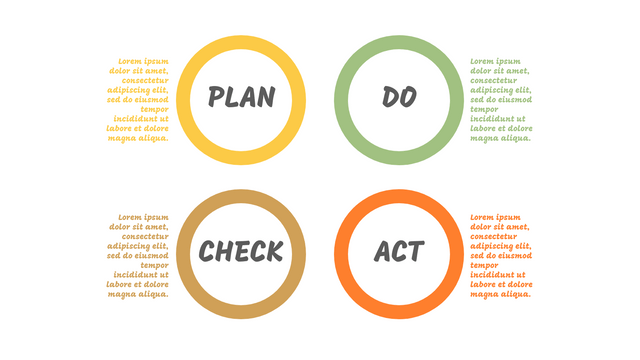

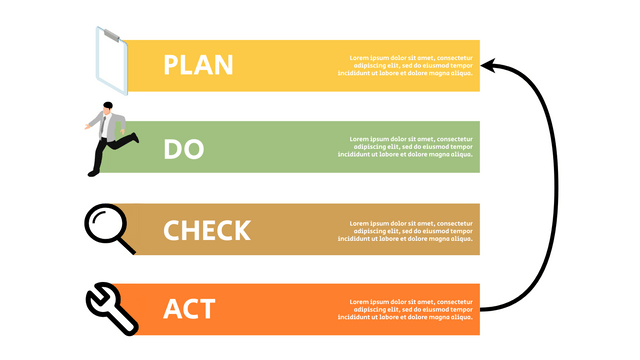

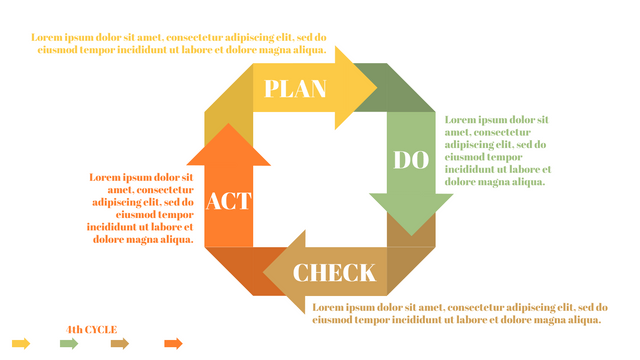

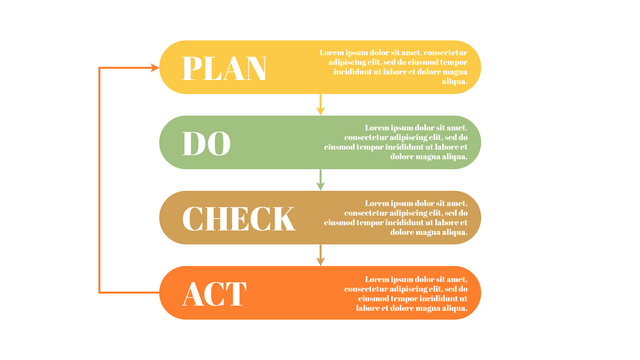

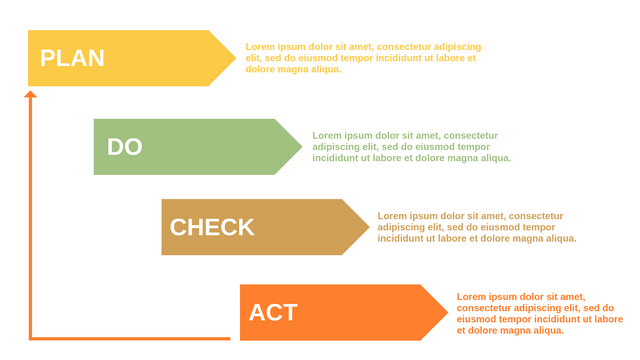

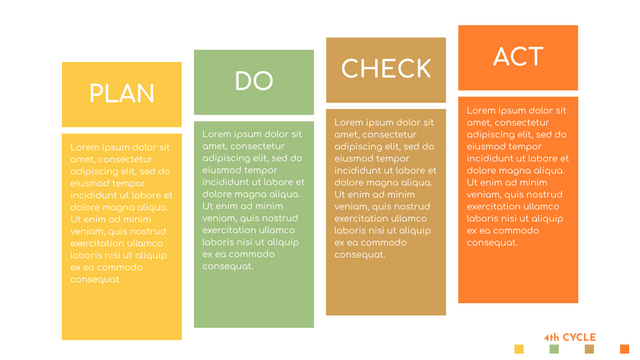

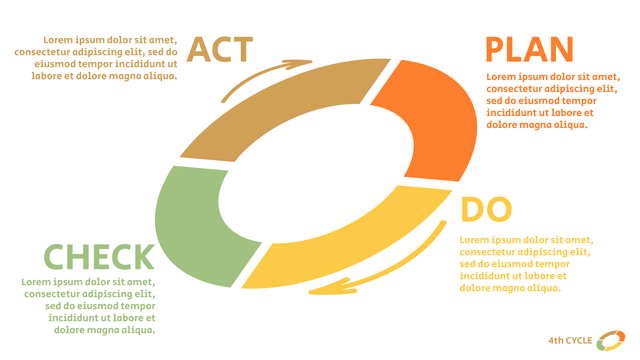

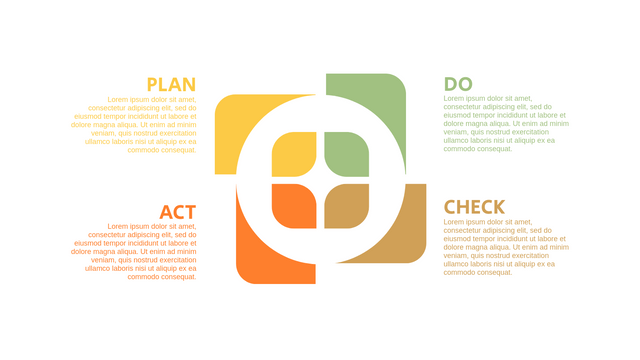

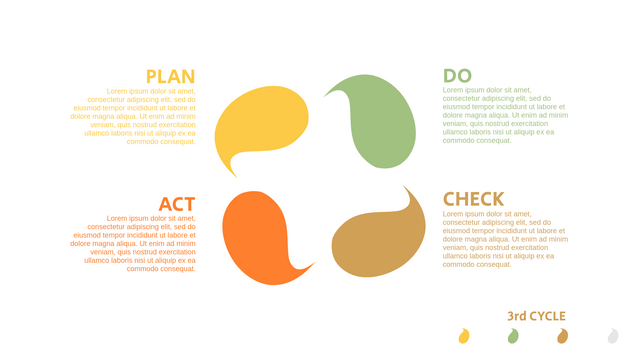

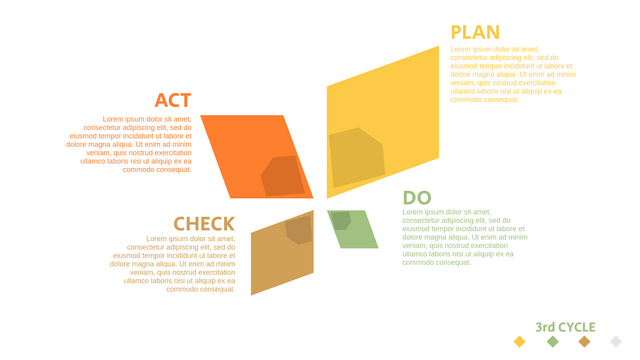

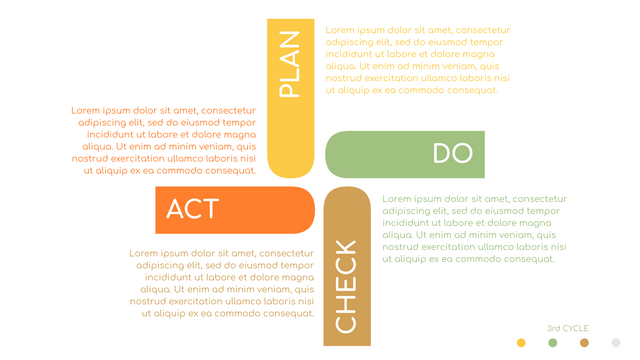

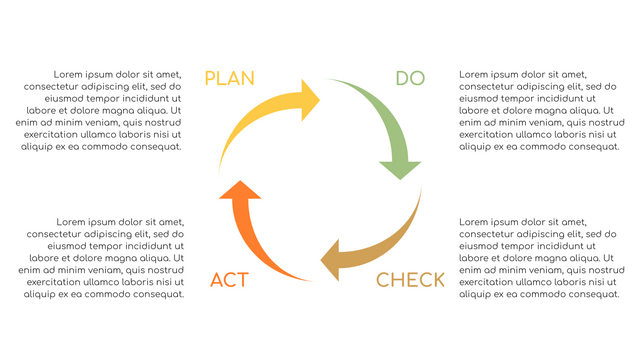

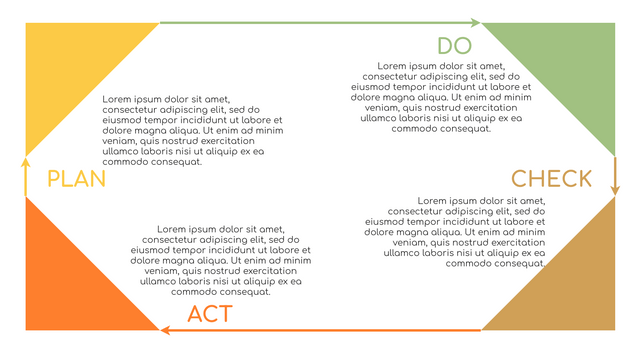

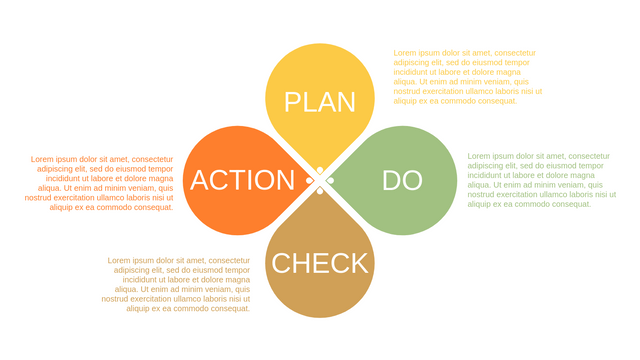

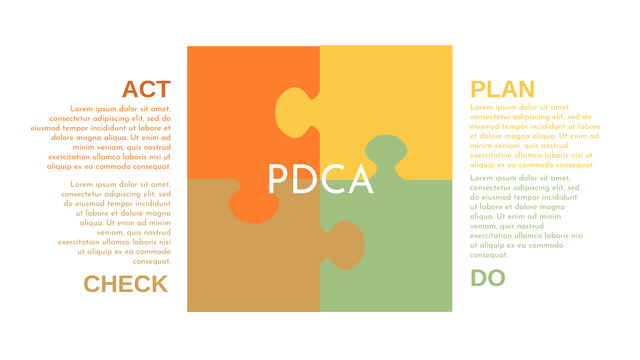

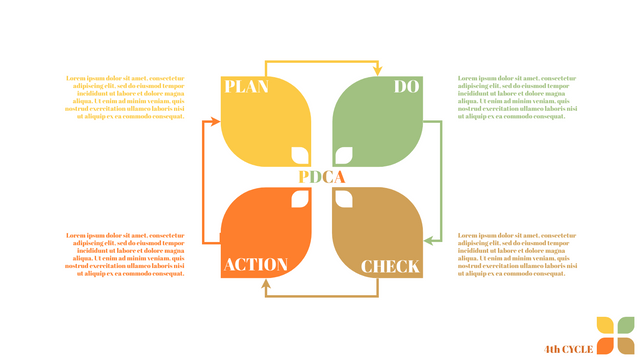

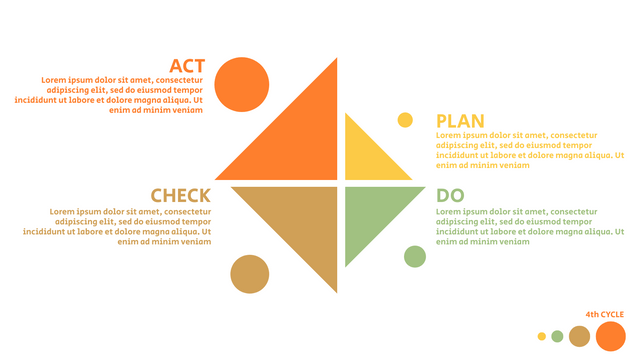

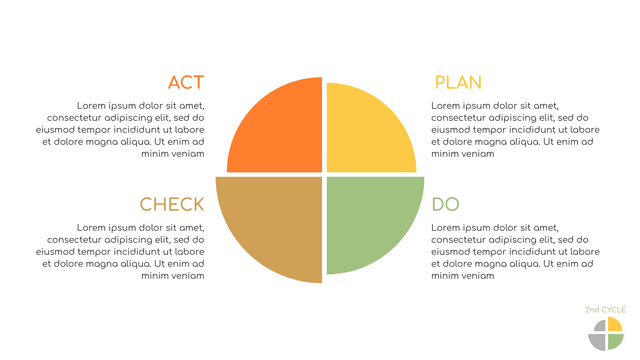

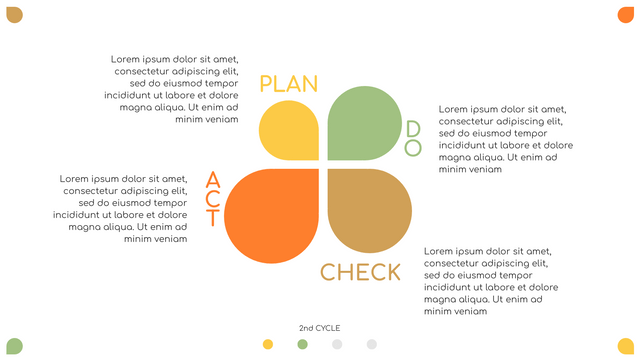

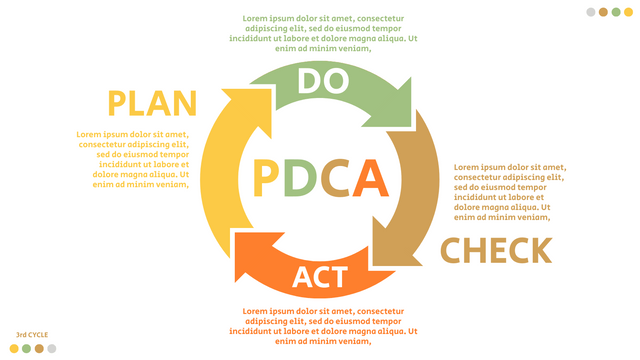

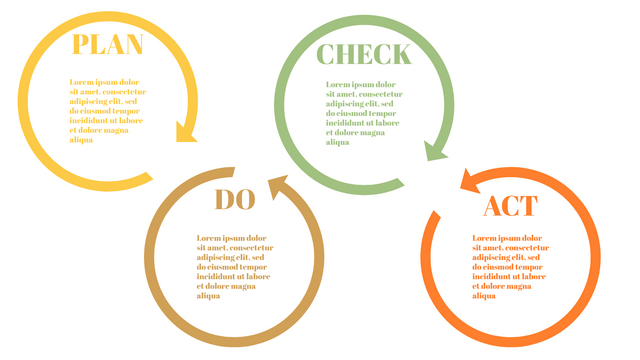

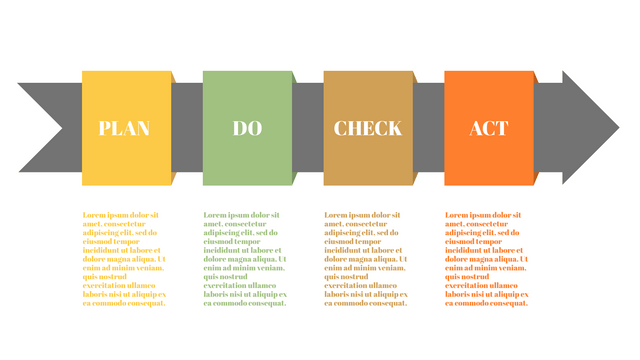

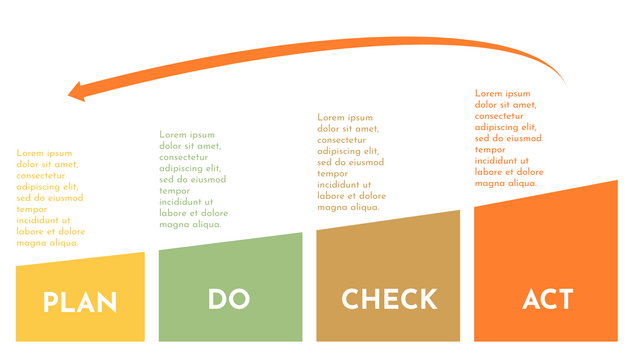

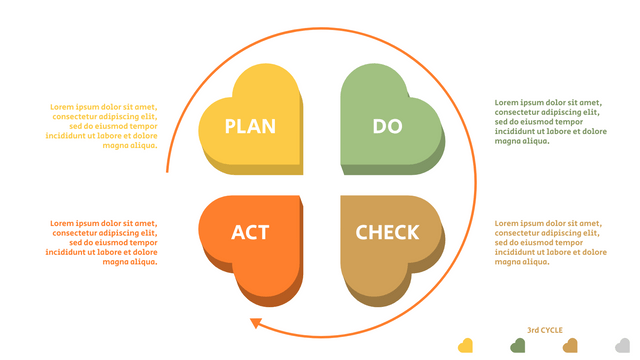

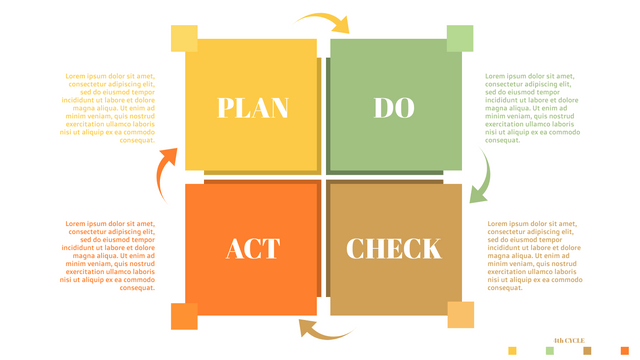

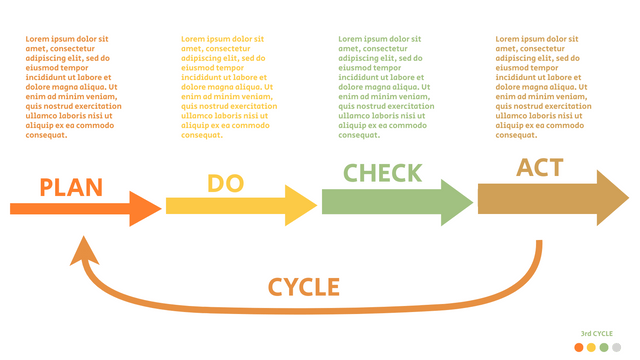

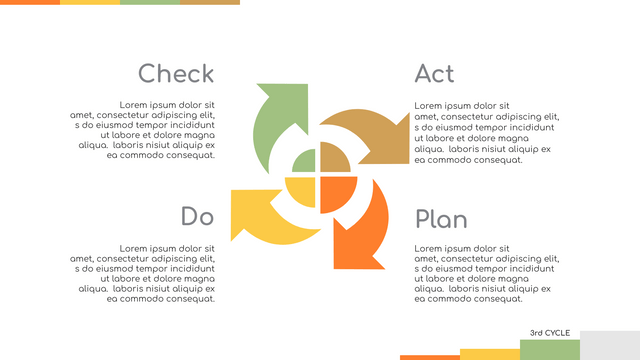

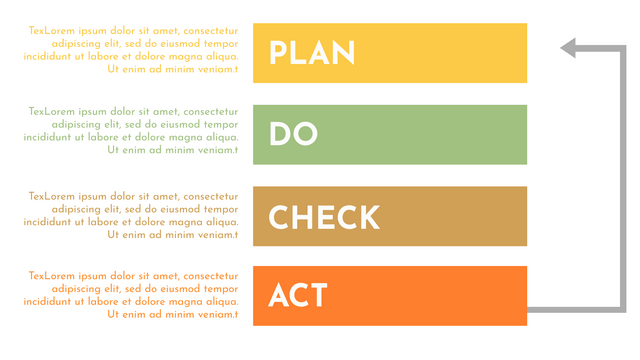

PDCA cycle is a logical working procedure for any activity to be carried out effectively, especially in quality management. The PDCA cycle consists of four important parts:

P (plan): determine the policy and objective, determine the activity plan

D (do) implementation: do it on the spot to realize the contents of the plan

C (check): check the effect, compare the actual work result with the expected goal, and check the implementation of the plan

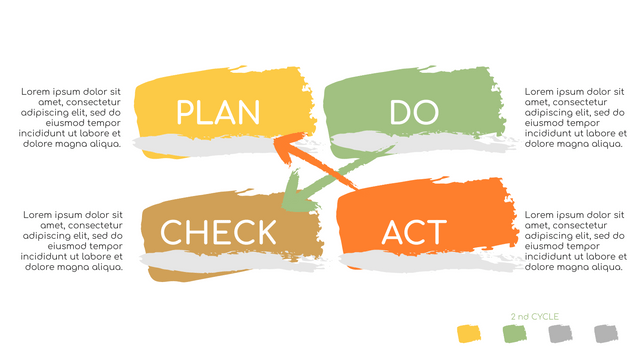

A (action) processing: the results of the summary inspection are processed, and the successful experience is affirmed and appropriately promoted and standardized; the lessons of failure are summarized to avoid recurrence; the unsolved problems are put into the next PDCA cycle.

The four parts constitute a complete, unified and continuous PDCA cycle. The above four processes do not end in one run, but go on round and round.